Flexible Screw Conveyors

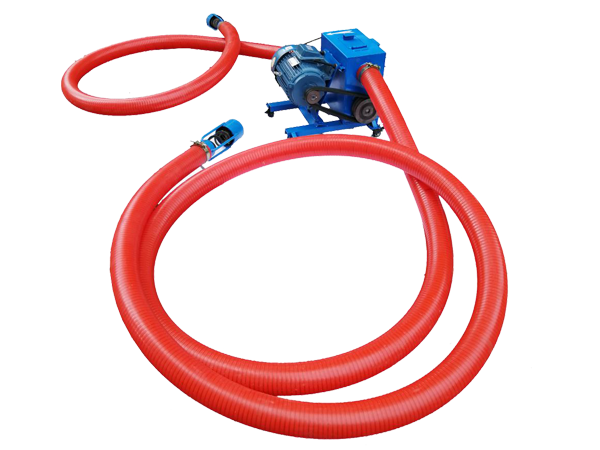

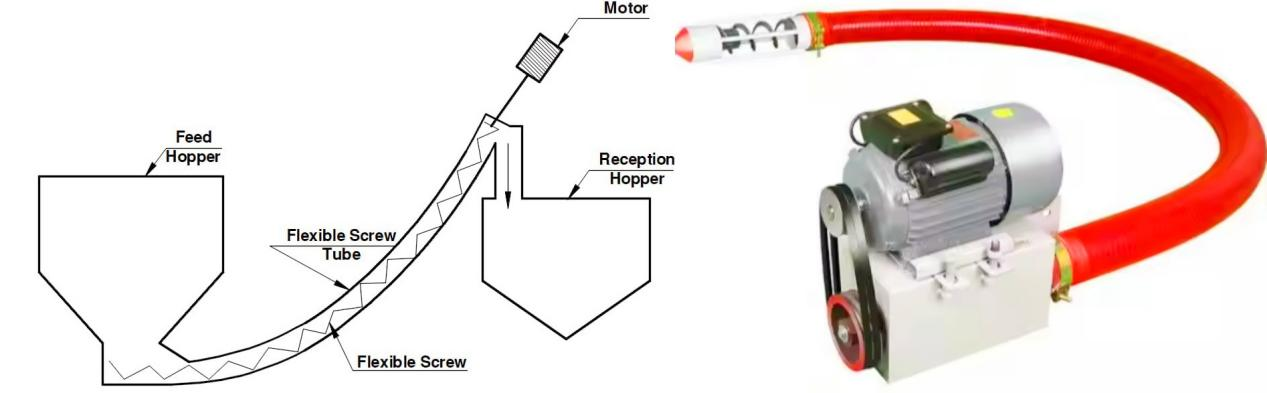

Flexible screw conveyor is a continuous conveying equipment that uses a combination of polymer wear-resistant hose and spiral spring core, suitable for long-distance, multi-angle conveying of powder, granular and mixed materials. Its core advantage is that it can flexibly adapt to vertical, horizontal or curved conveying paths. At the same time, it is equipped with a screening module and supports 20-200 mesh multi-level screen configuration to meet the precise grading needs of materials of different particle sizes.

Conveying capacity: up to 0.5-20m³/h

Conveying distance: up to 30 meters

Tilt angle: support 0-90°free adjustment

Application: widely used in food, medicine, building materials and other industries

What is a flexible screw conveyors?

Flexible screw conveyors are suitable for enclosed conveying of powdery or small granular materials, and can be used to screen materials from 20 mesh to 200 mesh. Their maximum conveying capacity can reach 110 tons per hour. Common pipe diameters include Φ50, Φ75, Φ90, Φ114, Φ120, Φ130, and Φ140 mm. Conveying lengths can be customized, up to 30 meters. They can be equipped with various power sources such as electric motors, diesel engines, Mazda engines, and speed reducers. The screw can be made of carbon steel or 304/316 stainless steel, and the drive motor power ranges from 0.75 to 5.5 kW. The entire machine can be configured with control systems and other functional modules to meet the conveying needs under different working conditions.

-

Advantages of flexible screw conveyors

Flexible screw conveyors can transport materials vertically, at an angle, or horizontally, offering versatility for conveying bags, silos, trucks, and more. They boast long conveying distances, excellent sealing during operation, wide material adaptability, and are easy to clean and maintain.

High flexibility: It can be conveyed in a straight line or in a curved manner. It can easily bypass obstacles or pass through walls through small openings, allowing users to flexibly arrange equipment according to actual site and process requirements.

Easy to clean and maintain: The structure is simple and easy to disassemble. One person can disassemble the conveyor for cleaning in just a few minutes, and the motor can be reversed to empty the residual material in the conveying pipe, and then rinse it with water or cleaning fluid.

Wide range of applicable materials: Suitable for conveying various powdered, granular, spherical, flaky and other materials, including free-flowing and non-free-flowing materials and mixtures.

Good sealing performance: It can achieve closed conveying, effectively prevent material leakage and dust flying, keep the working environment clean, and other equipment such as filters can also be installed in the conveying system.

Considerable conveying distance: A single flexible screw conveyor can convey materials up to a vertical height of 10 meters or even higher, and a horizontal distance of about 15 meters. If multiple conveyors are connected in series, they can be conveyed farther and higher.

Accurate metering and conveying: With a spiral structure, the flow rate can be adjusted by adjusting the motor speed, and the accuracy and repeatability can reach less than 1%. It is often used in production processes with metering devices to meet the requirements for accurate material transportation.

Related parameters of flexible screw conveyors

|

Parameter name |

Typical value |

range |

Description and selection basis |

|

Structural parameters |

Pipe diameter |

50-300mm |

Determine the conveying volume, which needs to be selected according to the material particle size (usually 3-5 times the maximum particle size) |

|

Conveying length |

1-30m (single unit) |

Multi-stage series connection is required for ultra-long distances, and mobile equipment is usually ≤10m |

|

|

Spiral diameter |

40-250mm |

Related to the pipe diameter, usually 0.8-0.9 times the pipe diameter |

|

|

Pitch |

0.8-1.2 times the spiral diameter |

Small pitch for powder (to prevent dust), large pitch for granular materials (to improve efficiency) |

|

|

Performance parameters |

Speed range |

20-200rpm |

Powder Low speed (20-80rpm) is recommended, and high speed (80-200rpm) is recommended for granular materials |

|

Power requirements |

0.75-15kW |

Adjust according to the conveying distance, material density and inclination angle. Vertical conveying requires 30%-50% more power |

|

|

Maximum inclination angle |

No limit for horizontal conveying, vertical ≤90° |

When the inclination angle is greater than 30°, the speed needs to be reduced by 20%-30% to prevent the material from falling back |

|

|

Material parameters |

Pipe material |

Stainless steel (304/316L), carbon steel, plastic, rubber |

Food/pharmaceuticals choose 304/316L, chemical industry chooses PTFE lining, wear-resistant chooses rubber, and lightweight materials choose plastic |

|

Spiral blade material |

Stainless steel, carbon steel, wear-resistant alloy Highly abrasive materials (such as quartz sand) |

Need to spray tungsten carbide or ceramic coating |

|

|

Drive parameters |

Drive mode |

Electric (conventional), hydraulic (explosion-proof), pneumatic (no electric spark) |

Select hydraulic/pneumatic in explosion-proof environment, and electric + inverter in ordinary scenes |

|

Installation parameters |

Installation mode |

Fixed, mobile (with casters) |

Select mobile for temporary construction or storage and transportation, and select fixed for production line integration |

|

Diameter |

Length |

Voltage |

Power |

Capacity |

Weight |

|

100mm |

3m |

220V |

3KW |

5-6T |

43kg |

|

100mm |

4m |

220V |

3KW |

5-6T |

47kg |

|

100mm |

5m |

220V |

3KW |

5-6T |

51kg |

|

100mm |

6m |

220V |

3KW |

5-6T |

55kg |

|

100mm |

7m |

220V |

3KW |

5-6T |

62kg |

|

100mm |

8m |

220V |

3KW |

5-6T |

66kg |

|

100mm |

9m |

220V |

3KW |

5-6T |

70kg |

|

100mm |

10m |

220V |

4KW |

5-6T |

74kg |

|

100mm |

11m |

380V |

4KW |

5-6T |

82kg |

|

100mm |

12m |

380V |

4KW |

5-6T |

86kg |

|

120mm |

3m |

220V |

3KW |

7-8T |

48kg |

|

120mm |

4m |

220V |

3KW |

7-8T |

52kg |

|

120mm |

5m |

220V |

3KW |

7-8T |

56kg |

|

120mm |

6m |

220V |

3KW |

7-8T |

60kg |

|

120mm |

7m |

220V |

4KW |

7-8T |

60kg |

|

120mm |

8m |

220V |

4KW |

7-8T |

71kg |

|

120mm |

9m |

220V |

4KW |

7-8T |

75kg |

|

120mm |

10m |

220V |

4KW |

7-8T |

79kg |

|

120mm |

11m |

380V |

4KW |

7-8T |

89kg |

|

120mm |

12m |

220V |

4KW |

7-8T |

93kg |

|

100mm |

20m |

380V |

7.5KW |

5-6T |

150kg |

|

100mm |

25m |

380V |

7.5KW |

5-6T |

170kg |

|

120mm |

20m |

380V |

7.5KW |

6-7T |

180kg |

|

120mm |

22m |

380V |

7.5KW |

6-7T |

200kg |

Types of flexible screw conveyors

|

Classification method |

picture |

Specific types |

Features |

Applicable scenarios |

|

By driving mode |

|

Electric flexible screw conveyor |

Strong power, stable operation, the conveying speed can be accurately controlled by the motor speed regulator |

Applicable to material conveying scenarios of various sizes |

|

|

Manual flexible screw conveyor |

Simple structure, low cost |

Applicable to small batch and short distance material transportation, often used in some small workshops or laboratories and other places |

|

|

By conveying pipe material |

|

Plastic conveying pipe flexible screw conveyor |

Has the advantages of light weight, corrosion resistance, wear resistance, good insulation performance, etc., and the price is relatively low |

Applicable to conveying some materials with high hygiene requirements and non-abrasive materials, such as food, medicine, chemical raw materials, etc. |

|

|

Metal conveying pipe flexible screw conveyor |

High strength, good rigidity, high temperature resistance, wear resistance, can adapt to harsh working environment |

Can be used to convey abrasive and high temperature materials, such as ore, slag, etc. |

|

Scene Type |

Image Parameters |

Typical Conveying Distance |

Typical Conveying Capacity |

Brief Application Scene Description |

|

Diesel Type |

|

5-25 m |

1-8 t/h |

No-power environment, temporary or field operations |

|

Handheld Type |

|

1-3 m |

0.1-0.5 t/h |

Small batch, short distance, manual operation |

|

Power Type |

|

3-20 m |

0.5-15 t/h |

Regular industrial continuous conveying |

|

Intermediate Shaft Type |

|

10-40 m |

5-30 t/h |

Long-distance or multi-channel conveying |

|

Mazda-driven Type |

|

5-30 m |

2-20 t/h |

High reliability, continuous heavy-duty operation (refer to Mazda technical standards) |

|

Ordinary Motor Type |

|

3-15 m |

0.5-10 t/h |

Cost priority, standard working conditions |

Video of flexible screw conveyors

Flexible screw conveyors design

Flexible screw conveyors is a continuous conveying equipment that uses the rotation of spiral blades to push the material along the flexible tubular trough. It is widely used in the horizontal, inclined or vertical conveying of powder, granular and small pieces of materials.

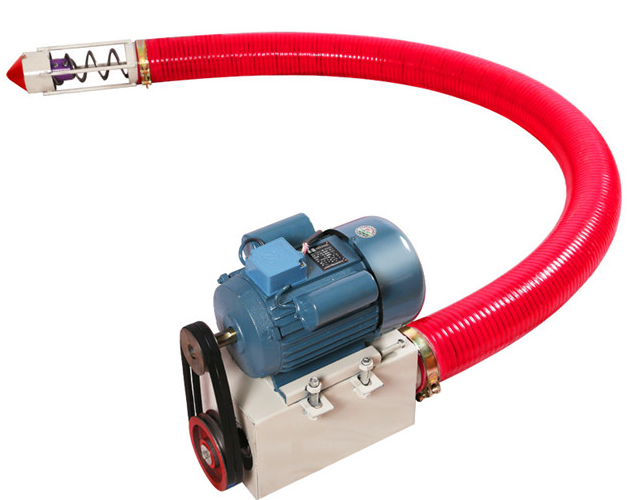

Flexible spiral body: Made of spring steel wire or flexible steel belt, the surface is covered with wear-resistant materials (such as nylon, rubber), which can be bent to form a U-shaped or tubular channel. The spiral pitch is adjustable to adapt to different material properties (such as fluidity, particle size).

Drive device: The motor and the speed machine drive the spiral shaft to rotate, the speed range is usually 20-200rpm, and frequency conversion speed regulation is supported.

Feed/discharge port: The inlet can be equipped with a vibrating feeder or a screw feeder, and the outlet can be connected to a valve or a material distributor.

Support structure: The flexible pipe is fixed by a hanging device or bracket, and a certain angle of bending is allowed (usually ≤90°).

What is the working principle of flexible screw conveyors?

The material enters the flexible conveying pipe through the feed port, moves forward along the conveying pipe under the push of the rotating spiral blade, and finally is discharged from the discharge port. Due to the flexibility of the conveying pipe, the conveying path can be arranged in three dimensions as needed to achieve horizontal, inclined or even vertical conveying.

What are the types of applicable materials for flexible screw conveyors?

Due to its unique structural design, the flexible screw conveyor is suitable for conveying materials in various forms, but it has certain requirements for the physical properties of the materials (such as particle size, humidity, viscosity, etc.). The following is a detailed description of its applicable materials and precautions:

Powdered materials include flour, powdered sugar, milk powder, starch, cement, PVC resin, and pharmaceutical powders. They require good flowability, a particle size not exceeding 0.5mm, and a moisture content not exceeding 5% to prevent clumping.

Granular materials include plastic granules, grains, fertilizer granules, pharmaceutical tablets, feed pellets, and seeds. They typically require a particle size between 1-10mm and moderate hardness to prevent sharp edges from abrading the pipe.

Small lump materials include small pieces of coal, ore fragments, small pieces of dry matter from food, and ceramic fragments. The required blockage diameter should not exceed 1/3 of the pipe diameter to prevent clogging of the spiral blades.

What are the applications of Flexible Screw Conveyors?

Flexible screw conveyors, due to their unique advantages, have demonstrated their strengths in scenarios such as workshop material preparation, warehousing and transportation, space-constrained factories, and production lines requiring multi-point material input. Here are some specific applications:

Food processing industry: In flour mills, rice mills and other grain processing enterprises, it can be used to transport raw grains such as wheat and rice from storage bins to processing equipment. In candy factories, it can transport various raw materials such as sugars and chocolate beans. In seasoning production workshops, it can accurately transport powdered additives such as salt, sugar, monosodium glutamate, and spices to achieve precise batching.

Chemical industry: In fertilizer plants, it can transport powdered fertilizer raw materials such as urea and ammonium chloride. In pigment plants, it can transport pigment powders of various colors. In plastic particle production enterprises, plastic particles can be transported from granulators to storage silos or packaging equipment. In activated carbon production plants, it is used to transport activated carbon particles.

Pharmaceutical industry: In pharmaceutical factories, Chinese herbal medicine powders, chemical synthetic drug raw materials, etc. can be transported to reactors, mixing equipment or preparation equipment. In capsule production workshops, drug particles can be transported to capsule filling machines. In tablet production, it is used to transport pressed tablets to packaging equipment.

Building materials industry: In cement plants, cement can be transported from cement silos to concrete mixing plants or cement packaging machines. In gypsum board production plants, it is used to transport gypsum powder from storage silos to gypsum board forming equipment. In the production of architectural coatings, additives such as titanium dioxide and calcium carbonate can be transported to achieve precise batching and mixing.

Price of flexible screw conveyors

The price of flexible screw conveyor will fluctuate greatly according to the following main factors:

Conveying length: The longer the length, the higher the price. The price is lower within 3 meters

Pipe diameter/conveying capacity: Common pipe diameters are Φ50, Φ75, Φ90, Φ114 mm. The larger the diameter, the more expensive it is

Whether to have a level meter/electronic control: With automatic control system, level sensor and other accessories will increase the cost

Approximate market price reference (RMB):

|

Type |

Parameter example |

Price range (yuan) |

|

Small carbon steel type |

Φ50mm, 3 meters long, 0.75kW |

4000 ~ 7000 |

|

Standard stainless steel food grade |

Φ75mm, 4 meters long, 1.5kW |

8000 ~ 15000 |

|

Large high conveying capacity (Φ114) |

Φ114mm, 6 meters long, 3kW |

18000 ~ 30000 |

|

Multiple outlets, customized |

bend pipes, multiple outlets, PLC control, etc. |

25000 ~ 60000+ |

Additional information:

Second-hand machines: Cheaper, can be reduced by 30%~50%, but there are maintenance risks.

If you tell me your parameter requirements (such as conveying volume, material type, conveying length, etc.), Dahan Machinery can make a specific quotation based on the information you provide.

Flexible screw conveyors manufacturer

In the manufacture of flexible screw conveyors, our factory has developed a dual-mode design with and without shafts, taking into account the characteristics of the materials. This allows for efficient conveying of both fluid materials and fluid materials. For example, a custom tubular screw conveyor for a dairy company enables dust-free conveying of milk powder from the storage bin to the packaging line, increasing the product qualification rate to 99.8%. We are a trustworthy partner.