Handheld Grain Sucker

Handheld Grain Sucker

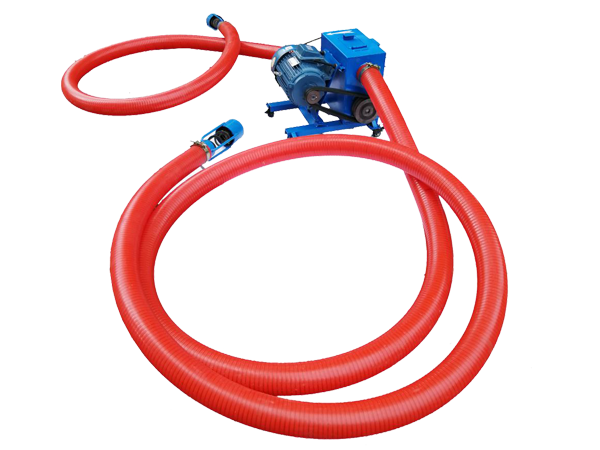

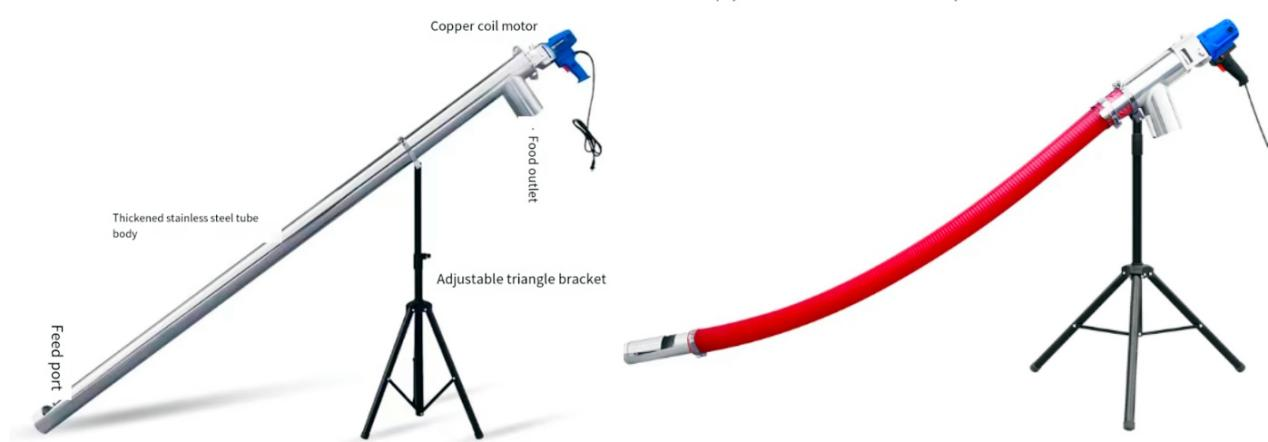

Handheld Grain Sucker is a portable pneumatic pipeline equipment designed for fast conveying and cleaning of small-scale grain, seeds or other pellets. It is transported through vacuum or pressure pipelines and is suitable for conveying dry, fluid materials with a sieve size of 20-200 (such as wheat, corn, beans). The handheld design is easy to operate and is suitable for cleaning, installation and unloading tasks in farms, granaries or small processing plants.

Delivery capacity: about 0.5-3t/h

Pipeline distance: nearly 10-50 meters

sucker: up to 4000-6500Pa

Applicable materials: corn, wheat, soybeans, rice, sorghum, pellet feed, etc.

What is handheld grain sucker?

Handheld Grain Sucker, also known as a portable grain sucker, is a portable device used to transport grain over short distances. Its suction nozzle is made of a special flexible material that not only fits tightly to the grain but also does not damage it, ensuring its integrity. The suction machine has strong suction power and can easily suck up a variety of common grains such as wheat, rice, and corn. The single-time suction capacity can reach 0.5-1 kg. It is suitable for grain handling and sorting in farms, granaries, and other places, greatly reducing the labor burden.

-

What is the purpose of a handheld grain sucker ?

The main purpose of a handheld grain sucker is to achieve the rapid transfer and cleaning of small-scale, flexible grain and grain warehouses. The specific uses include:

Loading and unloading: suck grains (such as wheat, corn, rice, beans) from trucks, grain piles or warehouses and transfer them to designated warehouses to reduce manual handling.

Warehouse management: clean up the residual grains at the bottom of the granary or adjust the stacks, keep the warehouse clean, and prevent the warehouse from mildew.

Small-scale processing: Storage pipelines provided for small grain processing plants, connecting screening, efficient packaging and other operations, suitable for loading and unloading of particles with a screening quantity of 20-200.

Emergency cleaning: Quickly clean up scattered grains or deal with emergencies, suitable for farms, docks and other scenes.

Seed protection: Low transportation rate (≤0.2%), suitable for high-value seeds or fragile docks to ensure quality.

Technical parameters of handheld grain sucker

|

Host type |

length (m) |

pipe diameter (inch) |

efficiency (hour/ton) |

motor power (kW) |

lifting height (m) |

machine weight (kg) |

|

220V~380V single power |

3m |

3.5 |

5-6 |

2.2 |

2 |

60 |

|

220V~380V single power |

4m |

3.5 |

5-6 |

3.0 |

2.5 |

64 |

|

220V~380V single power |

5m |

3.5 |

5-6 |

3.0 |

3.0 |

67 |

|

220V~380 V single power |

6 meters |

3.5 |

5-6 |

3.0 |

3.5 |

70 |

|

220V~380V single power |

7 meters |

3.5 |

5-6 |

3.0 |

3.5 |

73 |

|

220V~380V single power |

8 meters |

3.5 |

5-6 |

3.0 enlarged motor |

3.5 |

82 |

|

220V~380V single power |

9 meters |

3.5 |

5-6 |

3.0 enlarged motor |

3.0 |

85 |

|

220V~380V single power |

10 meters |

3.5 |

4-5 |

3.0 enlarged motor |

3.0 |

88 |

|

220V~380V single power |

11 meters |

3.5 |

4-5 |

3.0 enlarged motor |

3.0 |

92 |

|

220V~380V single power |

12 meters |

3.5 |

4-5 |

3.0 enlarged motor |

3.0 |

95 |

|

220V~380V single power |

3 meters |

4 |

7-8 |

3.0 |

2.0 |

65 |

|

220V~380V single power |

4 meters |

4 |

7-8 |

3.0 |

2.5 |

68 |

|

220V~380V single power |

5 meters |

4 |

7-8 |

3.0 |

3 .5 |

71 |

|

220V~380V single power |

6 meters |

4 |

7-8 |

3.0 |

3.5 |

75 |

|

220V~380V single power |

7 meters |

4 |

7-8 |

3.0 enlarged motor |

3.0 |

80 |

|

220V~380V single power |

8 meters |

4 |

7-8 |

3.0 enlarged motor |

3.5 |

83 |

What are the advantages of handheld grain sucker ?

The Handheld Grain Sucker can reduce damage to grains during use and has a strong suction force. Compared with other devices, it reduces the range of contact between the human body and grains and is suitable for all kinds of grains.

Protect grains: Suitable for dry granular feed (such as wheat and corn) with a screening mesh of 20-200. The flexible pipe can bypass obstacles and adapt to complex environments. The sucker nozzle is made of flexible material, which can fit tightly when adsorbing grains, while avoiding damage such as squeezing and scratching the grains, maintaining the integrity and quality of the grains, especially suitable for scenes with high requirements for grain quality.

High efficiency and energy saving: Built-in small vacuum pump with strong sucker force can quickly suck up grains, and the single grain sucker amount can reach 0.5-1 kg, which can effectively improve the efficiency of grain handling and sorting. Compared with some large mechanical equipment, it has lower energy consumption, which helps to selectively select specific grains (for example, damaged, infected or foreign objects) from larger samples.

Widely used: It can absorb all kinds of common grains such as wheat, rice, corn, etc. Whether it is large-grain corn or small-grain wheat, it can be stably adsorbed, with a wide range of applications, and can meet the processing needs of different grain varieties.

Precise processing, reducing pollution: It can accurately pick up and place individual grains, which is conducive to research, quality control and fine processing scenarios, minimizing direct contact between human body and grains, thereby potentially reducing the risk of contamination during sampling or transfer.

Application of handheld grain sucker

Handheld Grain Sucker is widely used in agriculture and grain processing due to its light and efficient design. The following are typical application scenarios and function analysis:

Post-harvest processing in the field:At the harvesting site, grains are often mixed with straw, soil or gravel. The handheld sucker with a 20-30 mesh screen can quickly absorb scattered grains directly in the field, and simultaneously screen out large impurities such as straw and broken leaves. The sucker force reaches 5-10kPa, and the processing capacity reaches 600-3000kg per hour, which greatly reduces the time of manual cleaning and reduces food waste.

Granary cleaning and bulk grain recovery:Scattered grains are easily accumulated in the corners and transportation gaps of the granary, and traditional cleaning is easy to mix with dust. The sucker uses a 10-40 mesh screen to filter in layers, which can accurately separate dust (below 60 mesh) and complete particles. It is combined with an anti-static hose to avoid the risk of dust explosion. It is especially suitable for dust-prone scenes such as wheat and rice, and the screening efficiency is ≥95%.

Pre-cleaning of the processing workshop:Before grain processing, hard impurities such as sand, gravel, and metal chips need to be removed. The sucker uses a 40-60 mesh stainless steel screen, which can absorb the raw materials on the production line and intercept foreign matter with a particle size of >0.3mm (such as crushed sand) to avoid damage to subsequent grinding machines or sorting equipment. If a metal detector is selected, it can also alarm the mixed iron filings in real time.

Farm feed preparation:Farms need to mix grains and additives, but the raw materials often contain moldy particles or lumps. The sucker uses a humidity sensor (detection range 5%-25%) to identify moist and agglomerated materials, and combines a 15-30 mesh screen to screen out deteriorated particles to ensure feed hygiene and safety, while avoiding clogging the feeding system.

Laboratory sample sorting:Agricultural research requires accurate acquisition of grain samples of specific particle sizes. The sucker is equipped with a 60-100 mesh precision screen, which can screen tiny impurities (such as insect eggs or disease particles) step by step, and is matched with a 1-5kg/min micro-flow mode to meet the laboratory's high-precision, small-batch sorting needs.

What is the working principle of the handheld grain sucker ?

The working process of a handheld grain sucker includes the following four stages. Through these stages, we can more clearly understand how the equipment sucks and transports grains, and in the later stage of use, we can know which stage has problems so that we can repair the equipment in time.

Start the power source (such as a motor or diesel engine): drive the centrifugal fan to run at high speed to generate strong negative and positive pressure airflow.

Negative pressure sucker stage: The fan forms a local vacuum at the sucker /sucker head through the grain sucker hose, and the external atmospheric pressure pushes the grain from the ground and the warehouse to be sucked into the sucker head.

Material airflow conveying stage: The inhaled grain is mixed in the high-speed airflow and transported to the discharge port through the sucker pipe. The material in the pipeline relies on the airflow to move and complete the pneumatic conveying process.

Discharge separation stage: Separate grains from gas at the collection barrel or cyclone separator, and the grains fall into the discharge port or grain storage container, and the gas is discharged through the exhaust port.

Manufacturer of Handheld Grain sucker

Dahan Vibration Machinery Co., Ltd. is a manufacturer specializing in the production of conveying and screening equipment, located in Xinxiang City, Henan Province, China. The following are the advantages of its handheld grain sucker :

Experienced: Dahan Machinery has many years of experience in the production of conveying equipment, exported to the United States, India, South Africa and other places.

Customized service: The pipe diameter, length and drive mode can be customized according to the distance between the dock and the pipeline and the on-site requirements. The design drawings will be provided within 72 hours and the customized production will be completed within 7 days.

Quality assurance: Provide 1 year free warranty, unconditional return due to quality problems within 10 days, and standard models will be shipped within 48 hours.

Customer evaluation: User feedback said that the equipment is easy to operate and saves manpower, and the Oxford cloth pipe is durable and does not harden due to low temperature.