High Temperature Screw Conveyor

High Temperature Screw Conveyor is a mechanical equipment specially used for conveying high temperature materials. It can operate stably in an environment with a temperature of 200℃ or even higher. It pushes the material forward through the rotation of the spiral blade to achieve continuous conveying.

Conveying length: 4-45m

Production capacity: 2.2-458m³/h

Screw diameter: 88-360mm

Applicable materials: flour, salt, monosodium glutamate, Chinese medicine powder, Western medicine powder, various feeds, etc.

What is a high temperature screw conveyor?

High temperature screw conveyor are designed for high-temperature environments, suitable for conveying granules, powders, liquids, and other materials at temperatures ranging from 200°C to 600°C. With a typical screening mesh size of 60 to 400 mesh, they are suitable for conveying a variety of fine and coarse materials. The superior performance of high-temperature screw conveyors makes them an ideal choice for continuous conveying of high-temperature materials, ensuring efficient and safe production processes.

Characteristics of high temperature screw conveyors

To cope with high temperatures, High Temperature Screw Conveyors are typically made of heat-resistant steel or special alloys to ensure they remain resistant to deformation and damage in high-temperature environments. Special insulation materials and structural designs eliminate the need for cooling devices, effectively reducing heat transfer and lowering energy consumption. They can transport large quantities of powdered, granular, lumpy, and mixed materials, with a single unit conveying distance of up to 20 meters, and flexible connections between multiple units can be extended as needed. They offer fully enclosed conveying to eliminate dust contamination. To prevent leakage of hot materials and the ingress of outside air, the equipment is typically equipped with highly sealed conveying ducts. High-temperature screw conveyors can operate stably under long-term high temperatures, minimizing failures and downtime, and ensuring production safety.

The high temperature screw conveyor can operate stably in extreme high-temperature environments ranging from 200°C to 900°C, meeting the conveying and feeding requirements of high-temperature materials. Its heat resistance ensures the durability of the equipment under long-term high-temperature exposure. Regarding specific conveying capacities, the equipment is professionally designed according to specific models, material characteristics, and operating conditions. Screw diameters range from 100mm to 150mm, with conveying capacities of 2 to 10 m³/h; screw diameters range from 200mm to 250mm, with conveying capacities of 10 to 30 m³/h; and screw diameters range from 500 to 600mm, with conveying capacities of 80 to 150 m³/h.

Classification of high temperature screw conveyors

|

Types |

Picture |

Features |

Applicable temperature range |

Typical application scenarios |

|

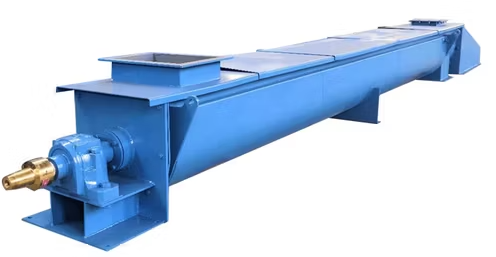

Horizontal screw conveyor |

|

Horizontal or slightly inclined installation, smooth conveying, suitable for medium and short distance conveying |

≤1000°C |

Conveying of high temperature materials such as metallurgy, chemical industry, and building materials |

|

Vertical screw conveyor |

|

Vertical or large-angle installation, small footprint, suitable for occasions with limited height |

≤600°C |

High temperature powder lifting (such as cement kilns, slag treatment) |

|

Inclined screw conveyor |

|

Adjustable inclination angle, with both horizontal and vertical conveying characteristics |

≤800°C |

Oblique conveying of high temperature materials (such as kiln inlet and outlet) |

Remarks:Different types of high-temperature spiral tube machines can be combined and used according to actual working conditions, such as tubular water-cooled spiral tube machines made of high-temperature resistant stainless steel. The specific selection needs to consider factors such as material particle size, viscosity, temperature, pipeline transportation, and environmental requirements.

Technical parameters of high temperature screw conveyor

|

LS type |

100 |

160 |

200 |

250 |

315 |

400 |

500 |

630 |

800 |

1000 |

1250 |

|

GX type |

|

|

200 |

250 |

300 |

400 |

500 |

|

|

|

|

|

Screw diameter (mm) |

100 |

160 |

200 |

250 |

315 |

400 |

500 |

630 |

800 |

1000 |

1250 |

|

Pitch (mm) |

100 |

160 |

200 |

250 |

315 |

355 |

400 |

450 |

500 |

560 |

630 |

|

Speed (r/min) |

140 |

120 |

90 |

90 |

75 |

75 |

60 |

60 |

45 |

35 |

30 |

|

Transport volume QΦ=0.33 (m3/h) |

2.2 |

7.6 |

11 |

22 |

36.4 |

66.1 |

93.1 |

160 |

223 |

304 |

458 |

|

Power Pd 1=10m (KW) |

1.1 |

1.5 |

2.2 |

2.4 |

3.2 |

5.1 |

4.1 |

8.6 |

12 |

16 |

24.4 |

|

Power Pd 1=30m (KW) |

1.6 |

2.8 |

3.2 |

5.3 |

8.4 |

11 |

15.3 |

25.9 |

36 |

48 |

73.3 |

|

Speed (r/min) |

120 |

90 |

75 |

75 |

60 |

60 |

45 |

45 |

35 |

30 |

20 |

|

Transportation volume QΦ=0.33 (m3/h) |

1.9 |

5.7 |

18 |

18 |

29.1 |

52.9 |

69.8 |

125 |

174 |

261 |

305 |

|

Power Pd 1=10m (KW) |

1.0 |

1.3 |

2.1 |

2.1 |

2.9 |

4.1 |

4.7 |

6.8 |

9.4 |

14.1 |

16.5 |

|

Power Pd 1=30m (KW) |

1.5 |

2.3 |

4.5 |

4.5 |

7 |

8.9 |

11.6 |

20.4 |

28.3 |

42.2 |

49.5 |

|

Speed (r/min) |

90 |

75 |

60 |

60 |

45 |

45 |

35 |

35 |

30 |

20 |

16 |

|

Transportation volume QΦ=0.33 (m3/h) |

1.4 |

4.8 |

15 |

15 |

21.8 |

39.6 |

54.3 |

97 |

149 |

174 |

244 |

|

Power Pd 1=10m (KW) |

0.9 |

1.2 |

1.9 |

1.9 |

2.5 |

3.4 |

4.3 |

5.4 |

8.1 |

9.5 |

13.3 |

|

Power Pd 1=30m (KW) |

1.2 |

2.2 |

3.8 |

3.8 |

5.4 |

6.8 |

9.2 |

16 |

24.4 |

28.6 |

39.9 |

|

Speed (r/min) |

75 |

60 |

45 |

45 |

35 |

35 |

30 |

30 |

20 |

16 |

13 |

|

Transportation volume QΦ=0.33 (m3/h) |

1.2 |

3.8 |

11 |

11 |

17 |

31.7 |

46.5 |

73.0 |

99.3 |

139 |

199 |

|

Power Pd 1=10m (KW) |

0.75 |

1.1 |

1.6 |

1.6 |

2.1 |

3.1 |

3.7 |

4.6 |

5.7 |

7.7 |

11 |

|

Power Pd 1=30m (KW) |

1.1 |

1.8 |

3.4 |

3.4 |

4.4 |

5.6 |

8 |

14 |

16.7 |

23.2 |

33 |

Video of high temperature screw conveyor

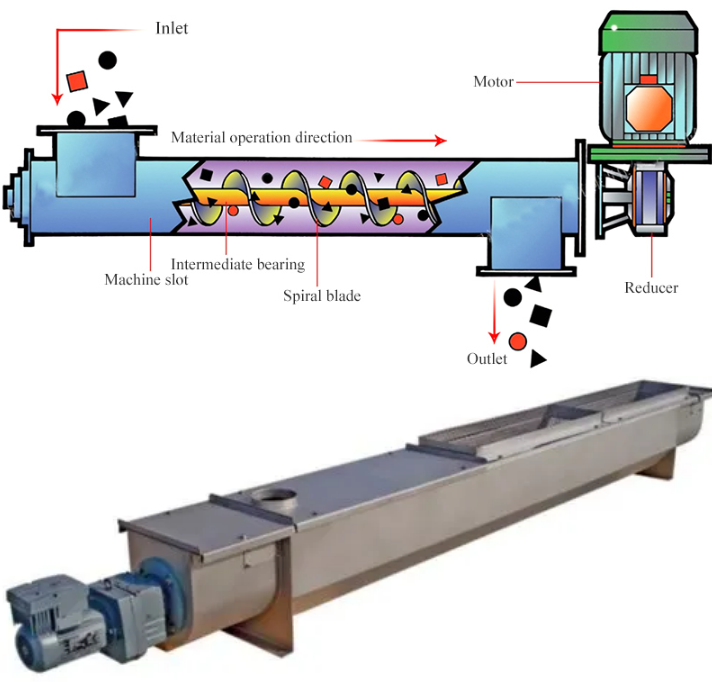

What is the working principle of a High Temperature Screw Conveyor?

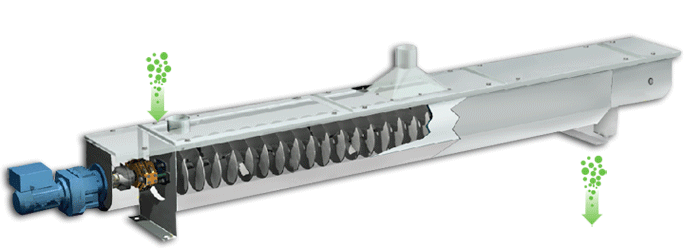

High Temperature Screw Conveyor uses a fixed trough made of high temperature resistant material as the conveying carrier. When the material enters the fixed trough, due to the gravity of the material and the friction between the material and the trough, the material accumulated at the bottom of the trough continues to rotate with the screw body and moves forward under the push of the rotating spiral blades, thereby realizing the conveying of the material from the feed port to the discharge port.

Structure of high temperature screw conveyor

The High Temperature Screw Conveyor consists of the following components: The spiral blades, welded to the central shaft, propel the material forward. The conveyor trough is a U-shaped or tubular trough that holds and guides the material. The feed and discharge devices, including the inlet and outlet, allow material to enter and exit the conveyor. The drive unit, available in single or dual drive configurations, provides power for the screw conveyor and drives the screw shaft. The bearings, including the head bearing and intermediate bearing, support the screw shaft, ensuring stable rotation and preventing material leakage.

What can high temperature screw conveyors be used for?

High Temperature Screw Conveyors are widely used in industrial scenarios that require pipeline high-pressure transportation, improve the characteristics of high temperature resistance, corrosion resistance and stable operation, and are suitable for the following purposes:

In the metallurgical industry, pipelines transport high-temperature slag, ore, and sintered materials at temperatures reaching 800-1000°C, with a screening size of 20-100 mesh, making them suitable for steelmaking and ironmaking production lines. In the chemical industry, pipelines transport high-temperature catalysts, chemical raw materials, or reaction byproducts, often used to discharge from high-temperature reactors, with feed temperatures of 300-600°C and a mesh size of 50-200 mesh. In the power industry, pipelines handle high-temperature fly ash and bottom ash from coal-fired power plants, with a transport capacity of 5-50 tons/ton-hour and suitable for environments with high sealing requirements. In the cement industry, pipelines supply high-temperature clinker or powder at temperatures reaching 500°C, with a mesh size of 80-150 mesh, making them suitable for cement production lines. For transportation and processing, pipelines transport high-temperature ash from furnaces and utilize water-cooling or heat-resistant alloy steel to prevent equipment overheating. Other industries, such as ceramics and glassmaking, require urgent raw materials or pipeline replacements, typically using pipelines with a length of 5-20 meters.

Differences between high temperature screw conveyor and ordinary screw conveyor

High temperature screw conveyor and ordinary screw conveyor have significant differences in design, material and applicable environment. The following are their main differences:

|

Features |

High temperature screw conveyor |

Ordinary screw conveyor |

|

Picture |

|

|

|

Applicable temperature range |

Usually can withstand 200°C ~ 600°C or higher |

Generally suitable for material transportation at room temperature or lower temperature, usually room temperature to 150°C |

|

Material |

Adopt high temperature resistant materials such as high temperature resistant steel, corrosion resistant alloy, stainless steel, special alloy |

Commonly used carbon steel, ordinary stainless steel, etc., with weak high temperature resistance |

|

Structural design |

Special structural design, such as stronger sealing, high temperature wear-resistant materials, reinforced bearings, etc. |

Suitable for conventional transportation, regardless of high temperature characteristics |

|

Corrosion resistance |

Need to have strong corrosion resistance, especially in high temperature environment |

The requirements for corrosion are relatively low, mostly used for conventional material transportation |

|

Sealing |

High temperature screw conveyors are usually designed with higher sealing to prevent leakage of high temperature materials |

Ordinary screw conveyors have lower sealing requirements and are not targeted at leakage of high temperature materials |

|

Application areas |

High temperature metallurgy, chemical industry, coking, power and other industries, used for high temperature material transportation Delivery |

Suitable for conveying food, building materials, fertilizers, plastics and other materials at normal or low temperatures |

High temperature screw conveyor manufacturer

Dahan Machinery is a well-known manufacturer of spiral pipe machines in China, specializing in the production of high-pressure spiral pipe machines, products include U-type, tubular, shaftless and other models, using high temperature resistant stainless steel or alloy steel materials, temperature resistance up to 1000℃ or more. The machinery provides customized solutions, with equipment pipeline capacity of 1-100 tons/hour, screening mesh of 20-200 mesh, and is widely used in metallurgy, chemical industry, power industry and other industries. The company is known for its high quality, durability and perfect after-sales service.Specific use According to the material characteristics (such as particle size, temperature, viscosity), pipeline distance and working conditions, choose the appropriate model

High Temperature Screw Conveyor Case

A factory needs to transport silicon powder particles at temperatures as high as 450℃ during its production process. Traditional conveying equipment is prone to deformation due to high temperatures or severe wear of the spiral blades, affecting production efficiency. To solve this problem, the factory adopted a high-temperature spiral conveyor. The machine body is made of high-temperature resistant alloy steel, the spiral blades undergo high-temperature heat treatment, and a high-temperature resistant ceramic coating is added to the inside of the barrel to reduce wear. The conveyor is equipped with a cooling device and thermal insulation protection to ensure the safety of the equipment's external temperature. In actual operation, the equipment can stably transport 30 tons of high-temperature powder per day, and the wear rate of the spiral blades is reduced by 50%, improving production efficiency and equipment lifespan.