Conveyor belt for agriculture

Conveyor belt for agriculture improve efficiency and reduce damage, suitable for the entire process from harvesting to packaging.

Material: PVC, PU, rubber, canvas composite belts

Width range: 300mm–2000mm, customizable

Conveyor speed: 0.1–3.0m/s, adjustable

Construction options: Flat, baffle, skirt, patterned belt

Load capacity: 20kg/m–200kg/m

Surface treatment: Smooth, non-slip, perforated, mesh

Operating temperature: -10°C to +80°C

Mobility: Fixed or mobile

Applications: Harvesting, sorting, washing, and packaging

What is conveyor belt for agriculture?

Conveyor belt for agriculture offer advantages such as high conveying efficiency, minimal crop damage, and strong adaptability. Through customization, such as using wear-resistant rubber materials, specific bandwidth, and speed adjustment, they can meet the conveying needs of various crops, from fruits and vegetables to grains. Their high efficiency and gentle conveying minimize crop damage and can be customized to the specific needs of different farms.

-

Conveyor belts for agriculture are continuous transport equipment used in agricultural production, primarily for transporting bulk or packaged materials such as grains, vegetables, fruit, potatoes, sugar beets, corn, rice, and seeds. These materials are often fragile, easily damaged, and vary in size and weight. Therefore, conveyor belt design must balance flexibility and load-bearing capacity. They are used in harvesting, sorting, cleaning, packaging, warehousing, and loading, significantly advancing agricultural mechanization and automation. Common types include fixed, mobile, telescopic, inclined, and belt-and-roller combinations. Conveyor distances can range from a few meters to hundreds of meters, depending on farm size and operating environment. Prices vary depending on length, belt width, material, and features, generally ranging from $800 to $5,000. High-end equipment equipped with automatic speed regulation or food-grade belts can cost $8,000 to $15,000.

What are the advantages of conveyor belt for agriculture?

The advantages of conveyor belt for agriculture are reflected in multiple aspects. First, in terms of applicable crop types, it can handle grains, fruits and vegetables, root crops, seeds, and processed and packaged agricultural products, giving it a wide range of applications. Secondly, in terms of applications, it can be used for initial post-harvest transportation in the field, as well as for sorting and packaging in warehouses and cold chain facilities. Common conveyor belt materials include PVC, PU, rubber, and stainless steel mesh belts, meeting varying requirements for food grade, wear resistance, and corrosion resistance. Bandwidth and load capacity can be flexibly customized based on crop size. Small fruits and vegetables can use widths of 300-500mm, while bulk grains and tuber crops require 600-1000mm or even wider. Modern equipment generally features variable frequency speed regulation, allowing adjustment within a range of 0.2-1.5 m/s to avoid collision damage to delicate crops like fruit. Regarding maintenance and cleaning, the conveyor belt features a simple structure and a removable and cleanable belt body. Some models can be treated with high-pressure water washing and food-grade detergents to reduce bacterial growth and ensure the safety and hygiene of agricultural products.

Conveyor belt specifications for agriculture

| Project | DY5051 | DY5071 | DY50101 | DY50102 | DY50102A | DY50151 | DY50152 | DY50152A | |

| Captain(m) | 5 | 7 | 10 | 10 | 10 | 15 | 15 | 15 | |

| Bandwidth(mm) | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Belt speed(m/s) | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | |

| *large conveying height(m) | 1.63 | 1.59 | 1.77 | 4.52 | 4.52 | 1.61 | 6.32 | 6.32 | |

| Delivery capacity | m3>h | 160 | 160 | 160 | 125 | 125 | 160 | 125 | 125 |

| /h | 145 | 145 | 145 | 112 | 112 | 145 | 112 | 112 | |

| Tilt angle (degrees) | 13°59′ | 9°16′ | 6.5° | 10°~>22° | 10°~22° | 3.81° | 10°~22° | 10°~22° | |

| Electric drum | Model | DY1.4 | DY1.4 | DY1.4 | DY1.5 | DY1.3 | DY1.4 | DY1.6 | DY1.3 |

| Power KW | 2.2 | 2.2 | 2.2 | 3.0 | 1.1 | 2.2 | 4.0 | 1.1 | |

| Gross weight(kg) | 518 | 604 | 892 | 1126 | 1071 | 1225 | 1491 | 1491 | |

What is the price of agricultural conveyor belts?

The price of agricultural conveyor belts varies greatly, depending primarily on the length, width, material, and degree of automation. A typical small mobile conveyor belt (5-8 meters in length, made of PVC or rubber) typically costs between $800 and $1,500. These are suitable for warehouse loading and unloading and small-scale farms. A medium-sized fixed conveyor line (15-30 meters in length, with automatic speed control and a stainless steel frame) costs approximately $2,500 to $6,000. Large or customized conveyor systems (such as combined lines with washing, sorting, and drying functions) can cost upwards of $10,000 to $20,000. While the investment scale is directly linked to farm output, these systems offer excellent value for money in terms of reducing labor costs and improving efficiency.

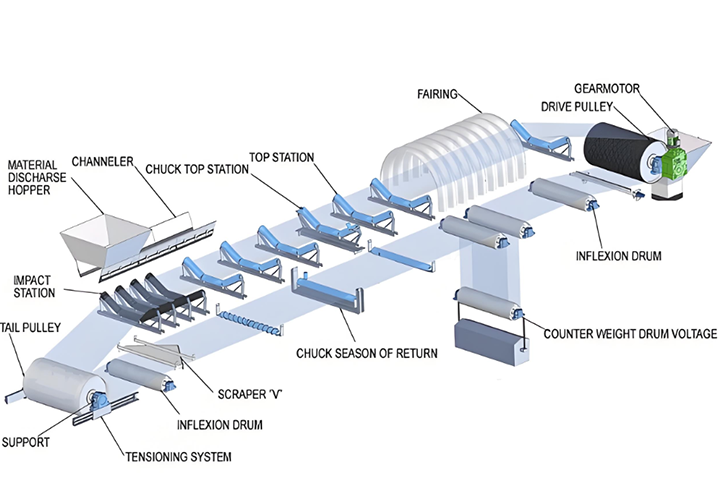

Structural Design of Conveyor Belt for Agriculture

The structural design of a conveyor belt for agriculture typically includes a frame, transmission, drive rollers, driven rollers, tensioning device, conveyor belt body, and cleaning device. The frame is typically constructed of carbon steel or stainless steel, ensuring both strength and rust resistance. Conveyor belts are generally flat, but can also be designed with corrugated sidewalls or cross-plates to prevent material from slipping, depending on crop needs. The drive system consists of a motor, reducer, and coupling to ensure stable power output. To accommodate the proneness of agricultural products to dirt and juice, conveyor belt surfaces are often designed to be wear-resistant, waterproof, and non-slip. Cleaners and flushing lines are also installed at key locations for easy maintenance and sanitation. Some high-end equipment also features automatic speed regulation and angle adjustment mechanisms, ensuring efficient operation in various harvesting and storage scenarios.

What materials are available for conveyor belt for agriculture?

For conveyor belts in agriculture, material selection is crucial and depends on operational requirements. Commonly used materials include PVC, PU, rubber, nylon, stainless steel, and composite materials. Detailed introductions to different materials are provided below.

PVC conveyor belts: Lightweight, grease-resistant, and corrosion-resistant, commonly used in fruit and vegetable sorting and packaging.

PU conveyor belts: Certified food-grade, flexible, and wear-resistant, suitable for direct contact with food, such as in fruit washing lines.

Rubber conveyor belts: High load-bearing capacity, wear-resistant and impact-resistant, suitable for conveying bulk or coarse materials such as grain, potatoes, and sugarcane.

Nylon or cotton canvas core belts: High tensile strength and flexibility, suitable for medium- and long-distance transport.

Stainless steel mesh belts: High-temperature resistant and easy to clean, often used in processes requiring drying, cleaning, or high hygiene requirements.

Composite conveyor belts with corrugated sidewalls and partitions: Suitable for inclined conveying or preventing bulk materials from slipping.

Conveyor belt selection for agriculture

In the agricultural sector, the material and construction of conveyor belts for agriculture should be tailored to the crop type. For fruits and vegetables, choose soft, scratch-resistant materials such as food-grade PVC or PU, and use flat belts or structures with side guards to prevent damage to the surface. Grains are suited to lightweight, breathable woven or rubber belts, while tubers such as potatoes and sweet potatoes require wear-resistant and impact-resistant rubber belts with deep grooves or bucket structures to prevent rolling and accumulation.

Different operational scenarios have varying requirements for conveyor belt width, speed, and surface treatment: Harvesting and sorting require a medium-width belt of 300-600mm and a low speed of 0.1-0.5m/s, with a non-slip or textured surface. Cleaning and packaging require water-resistant and corrosion-resistant materials with adjustable speeds of 0.2-1m/s. Long-distance transport requires a high-strength belt with a width of 600-1000mm, a medium-to-high speed of 1-2m/s, and possibly an anti-slip design. The surface treatment should balance cleanability and durability, such as an antimicrobial coating or an easy-to-wash structure.

Application of Conveyor Belts in Agriculture

Conveyor belt for agriculture have a wide range of applications. During field harvesting, mobile conveyor belts are often used for the initial transfer of crops such as potatoes, sugar beets, and onions, reducing manual handling. In fruit and vegetable processing plants, conveyor belts are used in conjunction with cleaning and grading machines to automatically clean, sort, and grade products, ensuring consistent product quality. In grain storage, large rubber conveyor belts are used to transport wheat, corn, soybeans, and other products, facilitating loading and unloading. In cold chain logistics and packaging, PU or PVC food-grade conveyor belts are used to transport packaging boxes and frozen foods, maintaining production line continuity. Furthermore, some smart agricultural parks combine conveyor belts with automatic sorting robots to achieve fully automated logistics and transportation. Conveyor belts for agriculture are not only highly efficient tools for the primary processing and distribution of agricultural products, but also crucial equipment for promoting the mechanization and intelligentization of modern agriculture.

Conveyor belt for agriculture case study

A fruit and vegetable cooperative faced pressure during the peak tomato harvest season. Traditional manual handling was inefficient, resulted in high fruit breakage rates, and rising labor costs severely hampered the cooperative's profitability and development.

Solution: The cooperative introduced a modular plastic chain conveyor system. This system, approximately 200 meters long, runs from the greenhouse harvesting area through sorting, washing, packaging, and loading. The conveyor belt features gentle conveying, is washable, and has an adjustable incline, adapting to the complex flow from the field to the workshop.

Implementation Results: Harvesting and processing efficiency increased by approximately 60%, effectively managing the peak harvest season; tomato breakage rate decreased from 8% to below 2%, increasing commercial value; labor requirements for handling were reduced by approximately 40%, lowering long-term operating costs; and the easy-to-clean conveyor belt ensured the cleanliness and hygiene of the fruits and vegetables.

Conveyor belt for agriculture supplier

DaHan Machinery manufactures Conveyor belts for agriculture using materials such as wear-resistant rubber, anti-static PVC, corrosion-resistant polyurethane, or food-grade materials. Specifications such as width, length, thickness, and number of layers, as well as accessories like sidewalls, guide strips, skirts, and scrapers, can all be customized. The company is certified with a production and quality management system. Successful applications include grain storage, seed processing, and fertilizer conveying. Sample testing and on-site inspections are available.