PVC conveyor belt

PVC conveyor belts are industrial conveyor belts made of polyvinyl chloride (PVC) and are widely used in industries such as food, packaging, and logistics.

Width: 200-3000mm

Length: 2-100m

Thickness: 1-10mm

Pattern: Smooth/Grass

Joint: Hot-vulcanized/Snap-on

Function: Anti-static/Food Grade

Frame: Polyester (EP)

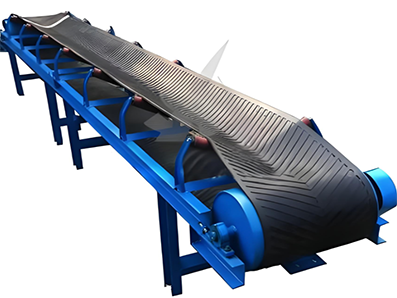

What is a PVC conveyor belt?

PVC conveyor belt are a widely used lightweight conveyor belt, commonly used to transport food, packaging, electronic components, tobacco, paper products, light industrial products, and some lightweight bulk materials. Belt widths typically range from 200mm to 3000mm, and lengths can be customized based on user requirements, generally from 2m to over 100m. Belt thicknesses range from 1mm to 10mm, depending on the weight of the conveyed material and the application scenario.

-

PVC conveyor belts can be designed with a variety of surface patterns, including smooth, grass, diamond, herringbone, and straight. The different patterns directly impact friction performance and conveying stability. Jointing methods typically include mechanical fastening, hot vulcanization, and cold bonding, depending on the equipment and conveying process requirements. PVC conveyor belts can be equipped with various features, such as anti-static, oil-resistant, and food-grade certification, making them suitable for use in the electronics, food, and pharmaceutical industries. Suitable pulley diameters typically range from 25mm to 300mm, with smaller diameters requiring greater belt flexibility. Pricing generally ranges from US$5 to US$50 per meter, depending on thickness, functionality, and customization requirements.

What are the advantages of PVC conveyor belts?

PVC conveyor belts have an operating temperature range of -10°C to 80°C and are made of a variety of materials. The core material affects strength, while the cover layer thickness determines wear resistance. They also feature a variety of surface properties.

Operating Temperature: Generally -10°C to 80°C. Some modified materials can enhance low- or high-temperature resistance.

Material and Variations: The base material is PVC (polyvinyl chloride), but derivatives such as PVK (anti-static) and PE (polyethylene) are also available. Different operating conditions require the selection of materials with properties such as anti-static, flame retardant, oil resistance, and acid and alkali resistance.

Core Material: Polyester (EP) or cotton (CC) is commonly used. The number of layers determines tensile strength and dimensional stability. More layers increase strength.

Cover Layer Thickness: The thickness of the upper and lower PVC cover layers determines wear resistance and service life. The upper cover layer is typically thicker to resist material friction and impact.

Surface Characteristics: Patterns include smooth, grass, diamond, herringbone, and straight lines. These patterns are primarily used to prevent slip and backflow, particularly effective on incline conveying. Some processes also include a Teflon (PTFE) coating for anti-sticking or a silicone coating for enhanced friction.

PVC conveyor belt product categories

PVC conveyor belts are mainly divided into three categories according to their structure: Z-type conveyor belts are used for material lifting in situations where vertical space is limited; inclined conveyor belts have baffles and crossbars and are designed for conveying materials at large angles; and horizontal conveyor belts are used for material transport on flat surfaces or with slight slopes.

Z-type PVC conveyor belt: Z-type conveyor belts feature a folded structure design, enabling vertical lifting of materials. The inclination angle is typically 60°~90°. The conveying capacity ranges from approximately 1~20 t/h, suitable for bulk granules or small parts, and lengths are usually between 3 and 15 meters. Used in industries such as grain, chemicals, and packaging, achieving space-saving vertical transportation.

Inclined PVC conveyor belt: Inclined conveyor belts have a continuous flat or slightly corrugated structure, with an inclination angle typically between 10° and 45°, meeting the needs of conveying materials on slopes. The conveying capacity ranges from approximately 2~50 t/h, and lengths can be customized according to production line needs, generally between 5 and 20 meters. Suitable for industries such as food, light industry, and electronic components, used for conveying materials from lower to higher levels.

Horizontal PVC conveyor belt: Horizontal conveyor belts have a simple structure, with flat or baffle designs. The conveying capacity ranges from 5~200 t/h, and lengths can range from 1 meter to 70 meters. Suitable for large-volume, continuous conveying, such as in mining, logistics, warehousing, and packaging production lines, enabling horizontal material transport and loading/unloading.

PVC Conveyor Belt Applications

PVC conveyor belts have a wide range of applications. In the packaging industry, they can be used for standard horizontal conveying, or they can be designed with baffles and skirts to achieve inclines or slight lifts. In the food processing industry, perforated belts are often required for ventilation or drainage. In logistics sorting, they may require curved conveying or automated equipment for sorting and merging.

In specialized processes, PVC conveyor belts can be used for cutting, spraying, cleaning, drying, and cooling. For example, cleaning conveyor belts on food factory assembly lines often require food-grade certification and water resistance; spraying plants may require chemical resistance; and cooling processes require good low-temperature flexibility.

In terms of environmental conditions, PVC conveyor belts are more suitable for indoor use, typically with a temperature range of -10°C to 80°C. If used outdoors, care should be taken to avoid prolonged exposure to UV rays or ozone to prevent accelerated aging. For oily, acidic, alkaline, or chemical environments, select specialized oil- and acid-resistant models. For high-humidity environments, waterproof and mildew-resistant properties are also important.

PVC Conveyor Belt Specifications

PVC conveyor belt structure

| Layer | Material | Function |

| Top Cover | PVC compound | Provides wear surface and protection |

| Fabric Layer(s) | Polyester (EP), Cotton, or Nylon | Strength and dimensional stability |

| Bottom Cover | PVC or fabric (optional) | For traction, grip, or sliding purposes |

Multi-ply options (1–4 plies) provide different levels of strength and flexibility.

PVC conveyor belt features

| Feature | Details |

| Material | Polyvinyl Chloride |

| Temperature Range | -10°C to +80°C (standard) |

| Surface Types | Smooth, rough top, diamond, crescent, or matte finish |

| Hardness | 60–80 Shore A |

| Tensile Strength | 120–400 N/mm depending on ply and thickness |

| Color Options | White, Green, Blue, Black, Transparent |

| Food Grade Options | Yes (FDA/EC-compliant PVC available) |

| Oil/Grease Resistance | Moderate (depending on PVC compound) |

| Flame Retardant Options | Yes (optional grades available) |

PVC conveyor belt applications

| Industry | Common Use Cases |

| Food Processing | Bakery, confectionery, meat & poultry, dairy |

| Logistics / Courier | Parcel sortation, distribution centers, airports |

| Pharmaceutical | Pill packaging, cleanroom environments |

| Textiles | Yarn and fabric transport |

| Electronics | Assembly lines for small parts |

| General Manufacturing | Parts conveying, machine integration, cutting lines |

PVC conveyor belt general specifications

| Parameter | Range / Options |

| Thickness | 1 mm – 6 mm |

| Ply Structure | 1-ply, 2-ply, 3-ply, 4-ply |

| Roll Widths | Up to 3,000 mm (custom widths available) |

| Length | Cut-to-length or in roll form |

| Top Surface Finish | Smooth, Matte, Rough Top, Diamond, etc. |

PVC conveyor belt types

| Type | Description |

| Smooth PVC Belt | For general conveying; easy to clean |

| Rough Top PVC Belt | For incline/decline transport; added grip |

| Anti-static PVC Belt | For electronics or explosive environments |

| Flame-retardant PVC | For underground or safety-critical applications |

| Food Grade PVC Belt | Compliant with FDA/EC food safety standards |

| Cross-rigid PVC Belt | With lateral stability for sidewall or cleated conveyor systems |

PVC vs PU Conveyor Belts

| Property | PVC Belt | PU (Polyurethane) Belt |

| Cost | ✅ Lower | ⚠️ Higher |

| Flexibility | ⚠️ Moderate | ✅ Excellent |

| Abrasion Resistance | ⚠️ Good | ✅ Very Good |

| Food Safety | ⚠️ Good (but limited) | ✅ Excellent (FDA/EC certified) |

| Temperature Range | ⚠️ Limited (up to 80°C) | ✅ Wider (-20°C to 100+°C) |

| Cleaning | ✅ Easy | ✅ Easy |

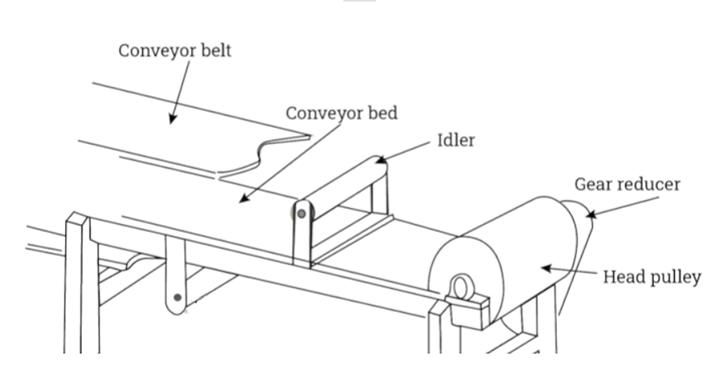

How does a PVC conveyor belt transport materials?

PVC conveyor belts are driven by a motor that rotates a drive roller, which in turn pulls the entire belt at a constant speed, causing materials to move forward in a predetermined direction under the action of friction. Its surface is smooth and wear-resistant, capable of supporting bulk or packaged goods while reducing slippage and spillage. With the addition of baffles, skirts, and other structures, the conveyor belt can maintain stable material transport in complex conditions such as ascents and turns. By selecting different patterns (such as grass textures and sidewalls) and thicknesses, anti-slip and load-bearing capacity can be further improved.

PVC conveyor belt case

In the workshop of a snack food factory, the engineering team customized a 600mm wide PVC conveyor belt to bridge the height difference between the mixing machine and the weighing machine. The conveyor belt features a finely textured, non-slip surface, ensuring stable transport of puffed materials at a constant speed. To reduce dust accumulation, a detachable scraper was added to the bottom, and a drive roller was installed to improve tension stability. After being put into operation, the single-line capacity increased from 1 ton per hour to 1.5 tons per hour, the number of material jams significantly decreased, and maintenance intervals were extended.

PVC Conveyor Belt Price

PVC conveyor belt prices are influenced by a variety of factors, including width, thickness, surface pattern, number of carcass layers, functional features (such as anti-static and food-grade certification), customization (including skirts and baffles), and order volume. The typical market price ranges from $5 to $50 per meter. Basic smooth belts are cheaper, at approximately $5-10 per meter. Products with food-grade certification or anti-static features cost around $15-25 per meter. Customized belts, multi-layer carcasses, or special wear-resistant patterns can cost $30-50 per meter. For long-term use, it is recommended to consider both longevity and energy efficiency.

PVC Conveyor Belt Supplier

As an experienced supplier, Auger-Conveyor offers customized conveyor belts, taking into account detailed operating conditions such as material particle size, moisture content, inclination angle, operating speed, and equipment drum diameter to provide specific model matching solutions. When producing PVC conveyor belts, customization is available for wear resistance grade, fabric layer structure, surface pattern, thickness tolerance, and overall length. Performance is verified through testing simulating actual customer loads, temperatures, and continuous operating times. By adjusting tension parameters and implementing routine maintenance plans, Auger-Conveyor helps customers minimize operational failure rates.