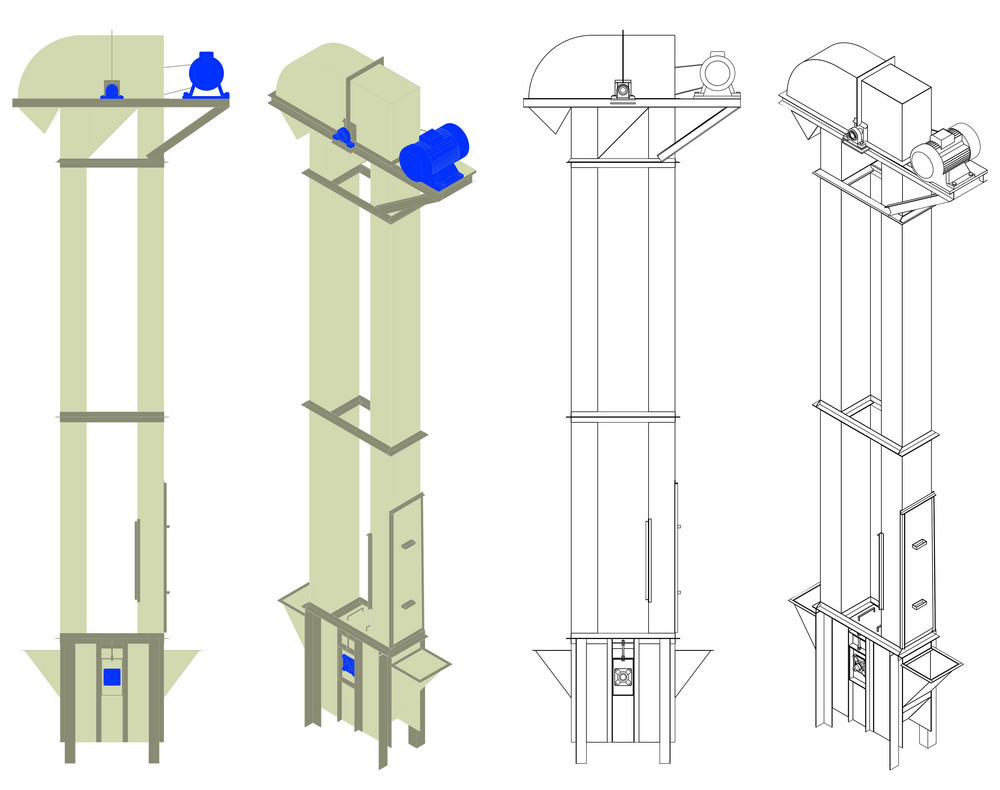

Feed Bucket Elevator

Commonly used in feed mills and agricultural facilities to lift feed into storage silos or boxes for later distribution.

Particle size: 4-180 mm

Production capacity: 0.65-69.6m³/h

Lifting height: 30 meters

Application: Mainly used in feed processing plants, livestock farms and other occasions for vertical transportation of feed pellets, powder and other materials.

Introduction of Feed Bucket Elevator

Feed bucket elevator is mainly used in feed processing plants, livestock farms and other places to vertically transport feed pellets, powder and other materials. The bucket design makes the materials less broken and damaged during transportation, maintaining the integrity of the materials.

Feed bucket elevators can be linked with other equipment (such as mixers and packaging machines) to realize automated production lines. The vertical design reduces the floor space and is suitable for places with limited space. It can be adjusted and configured according to different materials and production needs.

What is Feed Bucket Elevator used for?

Feed bucket elevators are widely used in the feed industry. They can continuously and stably convey feeds of various particle sizes.

Generally speaking, bucket elevators can effectively convey the following types of feed particle size ranges:

Feed pellets: including feed pellets of various sizes, from tiny particles to larger particles.

Pellet feed: granular feed such as grains, beans, corn, oatmeal, etc.

Powdered feed: including various powdered feeds, such as feed additives, powdered vitamins, minerals, etc.

Mixed feed: various mixed feeds, including mixtures of different particle sizes and shapes.

Usually, bucket elevators can convey feed with a particle size between 5mm-50mm. For some special feeds, such as powdered feed or super-large particle feed, conveying can also be achieved by selecting appropriate bucket types and chain speeds.

Application

Feed bucket elevator is a common material conveying equipment, mainly used in feed processing plants, livestock farms and other occasions, for vertical conveying of feed pellets, powder and other materials. The following are common applications of feed bucket elevators:

Feed processing plants: The elevator is used to convey raw materials, mixtures or finished feed from one process to another to realize the automatic conveying of the production line.

Livestock farms: Used to convey feed pellets or powder from the ground to the top of livestock and poultry feeding equipment, such as feeders, silos, etc., to ensure the continuous supply of livestock and poultry feed.

Feed warehouse: Used to convey feed vertically from the bottom of the warehouse to the top of the warehouse for easy storage and retrieval.

Feed distribution system: It can be used to distribute different types or ratios of feed to different feeders or areas to meet the needs of different animals.

Feed packaging line: Used to convey packaged feed bags from the bottom to the packaging machine above to realize the automated packaging process.

Feed mixing system: Used to convey various feed raw materials to the mixer for mixing to ensure uniform feed composition.

Feed batching system: It can be used to transport various feed raw materials from the storage bin to the weighing and batching system to realize the feed batching process.

Videos

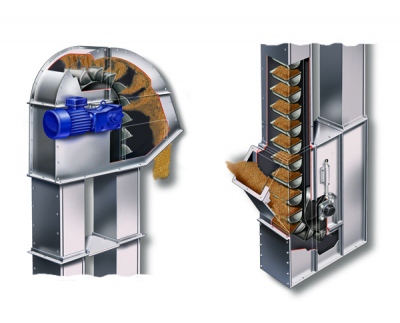

Working Principle

The working principle of the feed bucket elevator is: through the coordinated movement of the lifting bucket and the chain, the material is lifted from the feed port to a high place, and then the material is discharged through the discharge port. Specifically, the material first enters the lifting bucket from the feeding port, and as the lifting bucket rises, the material is lifted to a certain height, and then falls to the discharge port by gravity to complete the unloading of the material.

Advantages

Wide applicability: Feed bucket elevator is suitable for conveying different types of feed pellets, including pellets of various shapes and sizes.

Stable conveying: Bucket elevator conveys smoothly, and pellets are not prone to accumulation or overflow, ensuring a stable and reliable conveying process.

Protect feed quality: The bucket of the bucket elevator can effectively protect feed pellets, avoid pellet breakage or damage, and ensure feed quality.

Efficient and large-scale conveying: Bucket elevator can efficiently convey a large amount of feed pellets, which is suitable for production lines that require large-scale conveying and for situations where high conveying efficiency is required in feed production.

High space utilization: Bucket elevator has a compact structure and can convey feed vertically while occupying less space, which is suitable for production sites with limited space.

Technical Parameters of Feed Bucket Elevator

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

Supporting Equipment

Bucket elevator plays an important role in feed production line, used to transport materials vertically to different processing steps. It can be used in conjunction with a variety of equipment to achieve automation and efficiency of feed production.

With crusher: crush the raw materials into particles of suitable size, and then transport them to the mixer through bucket elevator.

With mixer: mix the crushed raw materials with additives, vitamins, etc., and then transport them to the pelletizer through bucket elevator.

With pelletizer: press the mixed materials into pellet feed, and the pelletized feed is then transported to the cooling screen through bucket elevator.

With cooling screen: cool and screen the pelletized feed, and transport qualified feed to the packaging machine.

With packaging machine: package the cooled feed into bags or bulk.

With storage silo: used to store various raw materials and finished feed, bucket elevator can transport materials from storage silo to production line or from production line to storage silo.

Price

The price of feed bucket elevator varies with brand, specification, material and other factors. Generally, the price range is between $5000 - $1000,0. The price of feed bucket elevators of big brands is relatively high, but the quality and performance are more guaranteed. At the same time, the specifications of the feed bucket elevator will also affect the price. The higher the conveying capacity and the higher the lifting height, the higher the price of the equipment.

In short, the feed bucket elevator is an important material conveying equipment, which has the characteristics of simple structure, reliable operation and strong adaptability. In the production process of different fields, the feed bucket elevator plays an important role, improving the efficiency of material transportation and the operation effect of the production line.

Solutions by Industry

-

Feed manufacturer

A power plant uses Tube screw conveyor to transport fly ash. Fly ash is a by-product of the power generation process and needs to be handled and transported efficiently. Tube screw conveyor transports fly ash from the collection system of the power plant to the storage or processing area by pushing it with a screw.

-

Livestock farm

A livestock farm needs to transport feed pellets from the warehouse to different feed machines to feed animals. It has selected a durable feed bucket elevator suitable for the livestock farm environment to meet the needs of vertical feed transportation.

-

Conveying sand

A feed processing plant needs to transport feed pellets of different types and specifications from the raw material warehouse to mixers, packaging machines and other equipment. The configuration of the bucket elevator is adjusted according to different needs to achieve a customized feed transportation solution.