Gypsum powder bucket elevator

Ideal for lifting gypsum powder to different heights within a processing plant or facility, the enclosed design helps control dust.

Lifting capacity: 5.4-40 tons/hour

Lifting height: ≤30 meters

Lifting speed: 1.4-2 m/s

Applications: It is suitable for various scenarios that require vertical transportation of gypsum powder or similar bulk materials, including gypsum board production lines, gypsum powder production lines and other building materials production processes.

Introduction

Gypsum powder bucket elevator is a mechanical equipment used to vertically transport bulk materials such as gypsum powder. It consists of a series of buckets connected to chains or belts. These buckets are driven by the circulating chain or belt and run along the track of the elevator to complete the lifting and unloading process of the material.

The gypsum powder bucket elevator is suitable for occasions where bulk materials such as gypsum powder need to be lifted vertically from the bottom to the top, such as material transportation in production lines, material replenishment of storage equipment, etc. This elevator can efficiently complete the vertical transportation of materials, save space, and improve production efficiency.

Application

Gypsum powder bucket elevator plays an important role in multiple application scenarios. Here are some specific application scenarios:

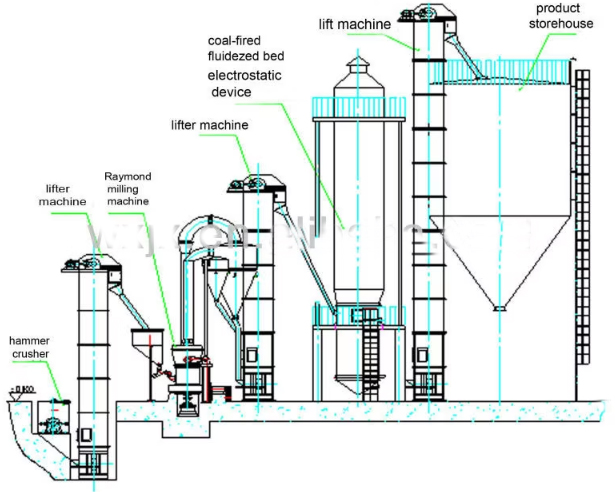

1. Gypsum powder production line: It can efficiently and continuously lift gypsum powder from the storage silo to the mixer.

2. Construction material production: It transports gypsum powder to the mixing equipment to ensure uniform mixing and efficient production of materials.

3. Agricultural soil improvement: It can transport gypsum powder from the warehouse to the fertilizer machine or mixing equipment for large-scale application.

4. Cement production: In the cement production process, gypsum powder is added to cement as a regulating material, and the elevator can efficiently transport gypsum powder to the cement mixer.

5. Waste treatment: It can transport gypsum powder from the storage area to the processing equipment.

6. Gypsum mine: It can operate stably under high load and harsh environment, and will be lifted from the mine to the ground for processing.

Bucket elevator adaptability to different types of gypsum powder

There are many types of gypsum powder, which can be divided into many types according to their physical properties, particle size, water content, etc. Bucket elevators have good adaptability to different types of gypsum powder.

Raw gypsum powder: Raw gypsum powder has large particles and strong abrasiveness. Bucket elevators can adapt to this material by selecting buckets and chain plates made of wear-resistant materials.

Cooked gypsum powder: Cooked gypsum powder has fine particles and good fluidity. Bucket elevators can use smaller buckets and higher lifting speeds to improve conveying efficiency.

Semi-hydrated gypsum powder: The properties of semi-hydrated gypsum powder are between raw gypsum powder and cooked gypsum powder, and bucket elevators are also more adaptable to it.

Other modified gypsum powder: Various modified gypsum powders, such as high-temperature resistant gypsum powder, waterproof gypsum powder, etc., can be transported by bucket elevators as long as their particle size and density are within the conveying range of bucket elevators.

Notes

For fine-grained gypsum powder, the following measures can be considered:

Install dust removal device: prevent dust from flying and improve the working environment.

Reduce chain speed: reduce the collision of materials in the hopper and reduce dust generation.

Videos

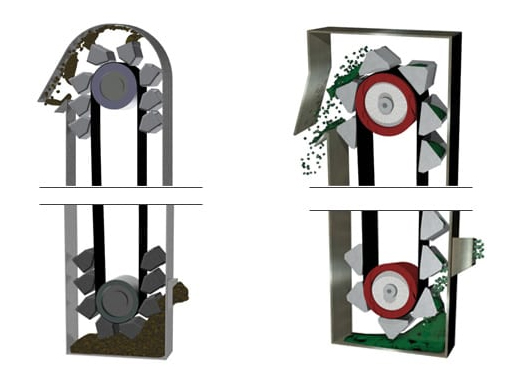

Working Principle

The working principle of the bucket elevator is to drive the main transmission device through the motor to drive the carrier up or down to achieve the purpose of conveying materials. During the whole process, the bucket elevator works circularly in the body, and the lifting and unloading operations are carried out alternately, realizing continuous and efficient material transportation.

Features and Benefits

Space Saving: Bucket elevators are compact in design and can efficiently move materials vertically, saving valuable floor space in industrial settings.

Dust Control: Gypsum powder bucket elevators can be equipped with dust collection systems to minimize dust emissions during material handling, ensuring a clean working environment.

Customizable Configuration: Bucket elevators can be customized to suit specific requirements such as height, capacity, and discharge options, making them versatile for different applications.

Reduced Material Degradation: The gentle handling provided by bucket elevators helps in minimizing material degradation, ensuring that the quality of the gypsum powder is maintained during transportation.

Technical parameters

| Model | Lifting capacity (m3/h) | Maximum material size (mm) | ||||

| Percentage of eligible % | ||||||

| 10 | 25 | 50 | 75 | 100 | ||

| NE15 | 16 | 65 | 50 | 40 | 30 | 25 |

| NE30 | 31 | 90 | 75 | 58 | 47 | 40 |

| NE50 | 60 | 90 | 75 | 58 | 47 | 40 |

| NE100 | 110 | 130 | 105 | 80 | 65 | 55 |

| NE150 | 165 | 130 | 105 | 80 | 65 | 70 |

| NE200 | 220 | 170 | 135 | 100 | 85 | 70 |

| NE200 | 320 | 170 | 135 | 100 | 85 | 70 |

| NE400 | 470 | 205 | 165 | 125 | 105 | 90 |

| NE500 | 600 | 240 | 190 | 145 | 120 | 100 |

| NE600 | 600 | 240 | 190 | 145 | 120 | 100 |

| NE800 | 800 | 275 | 220 | 165 | 135 | 110 |

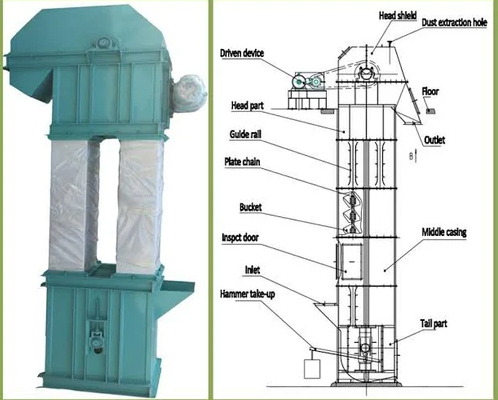

Composition Structure

The gypsum powder bucket elevator is mainly composed of the following parts:

Drive device: including motor, reducer, etc., to provide power for the elevator.

Casing: surrounds the internal parts of the elevator to prevent material splashing and leakage.

Upper and lower rollers: located at the top and bottom of the elevator, respectively, driving the chain or belt to run.

Chain: connected to the hopper to form the conveying system of the elevator.

Bucket: used to carry materials and move up and down with the chain or belt.

Tensioning device: maintains the tension of the chain or belt.

In order to better adapt to the conveying characteristics of gypsum powder, bucket elevators usually make some structural optimizations:

1. Hopper design: Considering the abrasiveness of gypsum powder, the hopper material is generally made of materials with good wear resistance, such as wear-resistant steel plates or rubber linings.

2. Sealing device: Sealing measures should be adopted at the connection between the casing and each component to prevent dust leakage.

3. Driving device: The variable frequency speed regulating device can adjust the operating speed of the elevator according to different conveying requirements to improve the conveying efficiency.

4. Dust removal device: Install dust collection devices at the top and bottom of the elevator to remove dust in time and improve the working environment.

Solutions by Industry