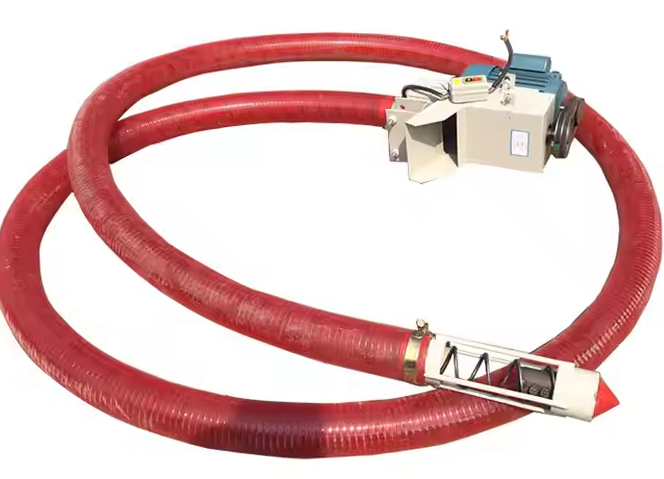

Grain Suction Machine Hose

Grain Suction Machine Hose

Grain Suction Machine Hose is a kind of equipment specially used for transporting and sucking grain and other granular materials. It realizes efficient material transfer through the hose system and is widely used in agriculture, grain processing and food industry.

Length: 3-12 meters (customizable)

Output: 2-20 tons/hour

Diameter: 100-160mm

Grain Suction Machine Hose Introduction

Grain Suction Machine Hose is a kind of equipment specially used for efficient transportation and suction of grain and other granular materials. The equipment transports grain from one place to another through the negative pressure of the hose, which is suitable for grain processing, warehousing and transportation industries. The suction speed can be adjusted according to demand, generally 5-20 tons/hour. The screening mesh is usually 20-80 mesh, which is used to ensure the purity of the material during the transportation process and avoid the mixing of impurities to adapt to materials of different particle sizes.

-

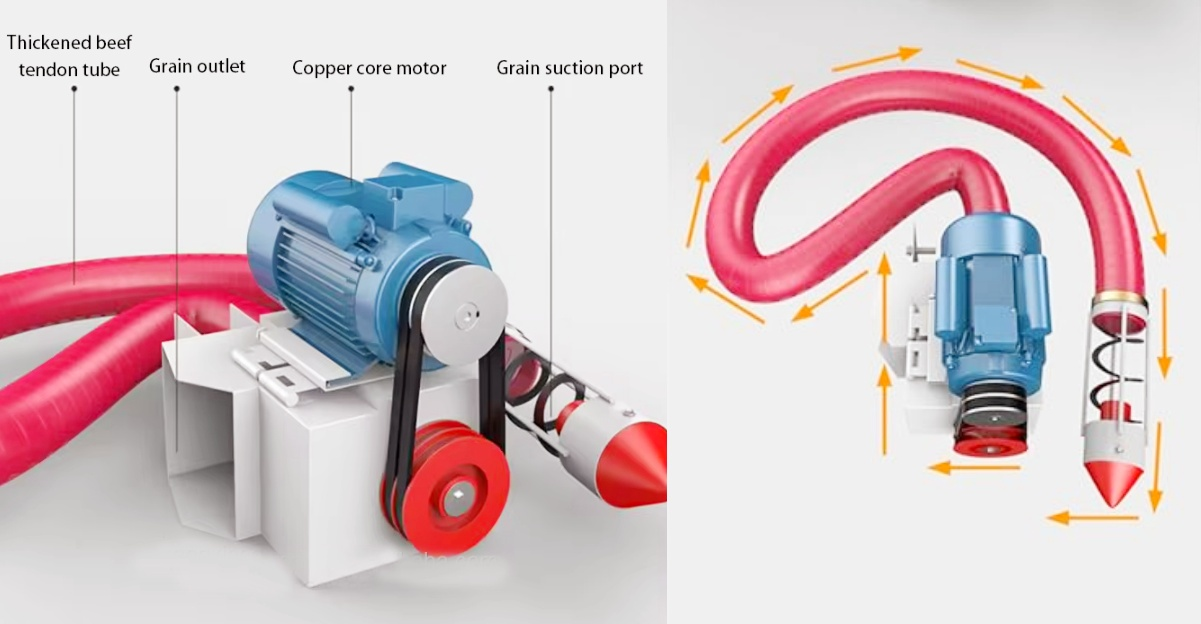

Working principle of a grain suction machine hose

Grain suction machines hose generally use a vacuum pump or fan to generate negative pressure, form airflow in the hose, and suck the grain into the pipeline. The material flows with the airflow and is eventually sent to the discharge port. Its key components include suction hoses, conveying hosts, power units (usually motors or diesel engines), and collection devices.

Video of a grain suction machine hose

Technical parameters of grain suction machine hose

|

Host type |

Length |

Pipe diameter (inch) |

Efficiency (hour/ton) |

Motor power (kW) |

Lifting height (m) |

Machine weight (kg) |

|

220V-380V single power |

3 meters |

3.5 |

5-6 |

2.2 |

2 |

60 |

|

4 meters |

3.0 |

2.5 |

64 |

|||

|

5 meters |

3.0 |

67 |

||||

|

6 meters |

3.5 |

70 |

||||

|

7 meters |

73 |

|||||

|

8 meters |

3.0 enlarged motor |

82 |

||||

|

9 meters |

3.0 Larger motor |

3.0 |

85 |

|||

|

10 meters |

4-5 |

88 |

||||

|

11 meters |

92 |

|||||

|

12 meters |

95 |

|||||

|

4 meters |

7.8 |

3.0 |

2.0 |

65 |

|

|

|

220V-380V single electricity |

4 meters |

4 |

7.8 |

3.0 |

2.5 |

68 |

|

5 meters |

3.5 |

71 |

||||

|

6 meters |

75 |

|||||

|

7 meters |

3.0 enlarged motor |

3.0 |

80 |

|||

|

8 meters |

3.5 |

83 |

||||

|

Note: Length and pipe diameter can be customized! |

||||||

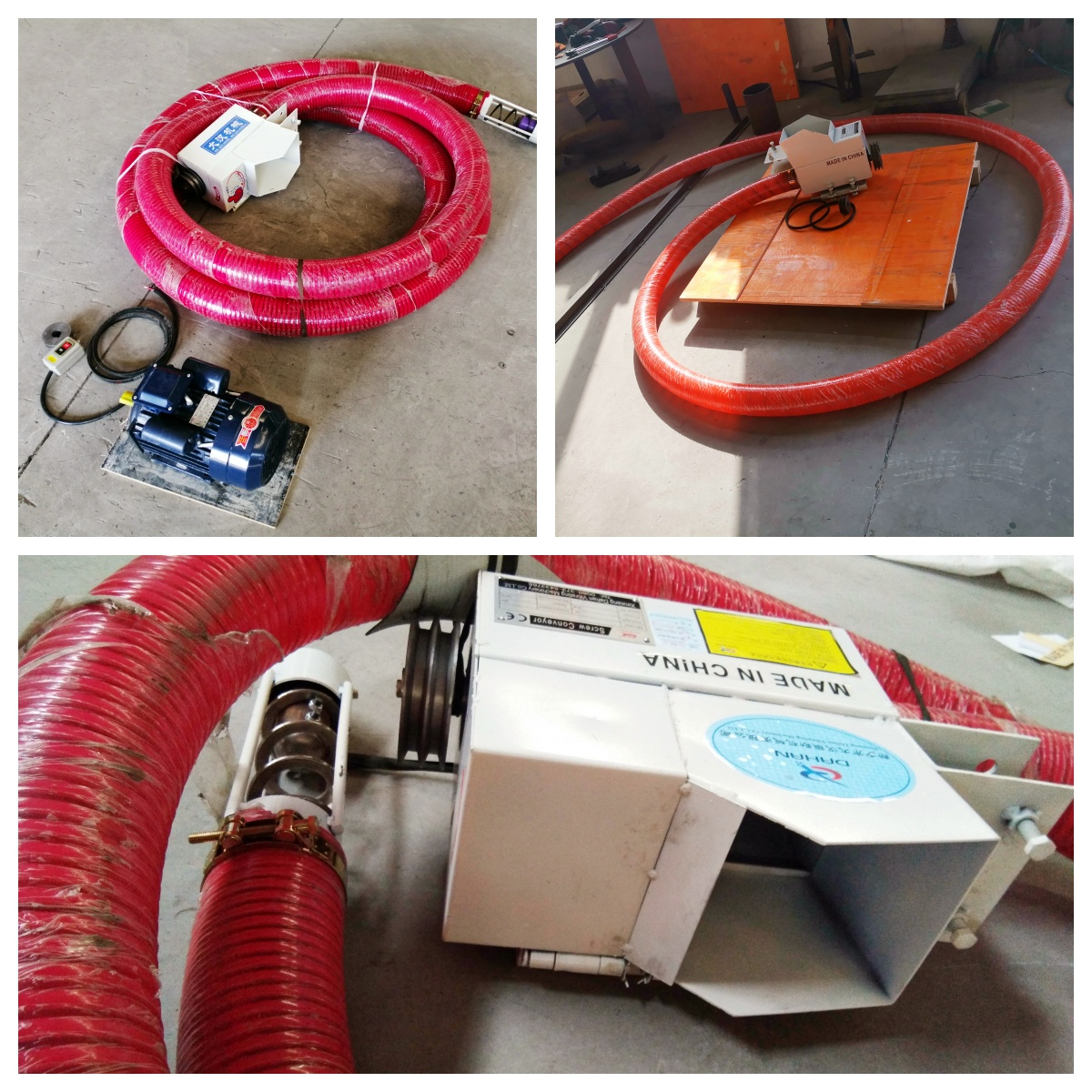

Structural composition of a grain suction machine hose

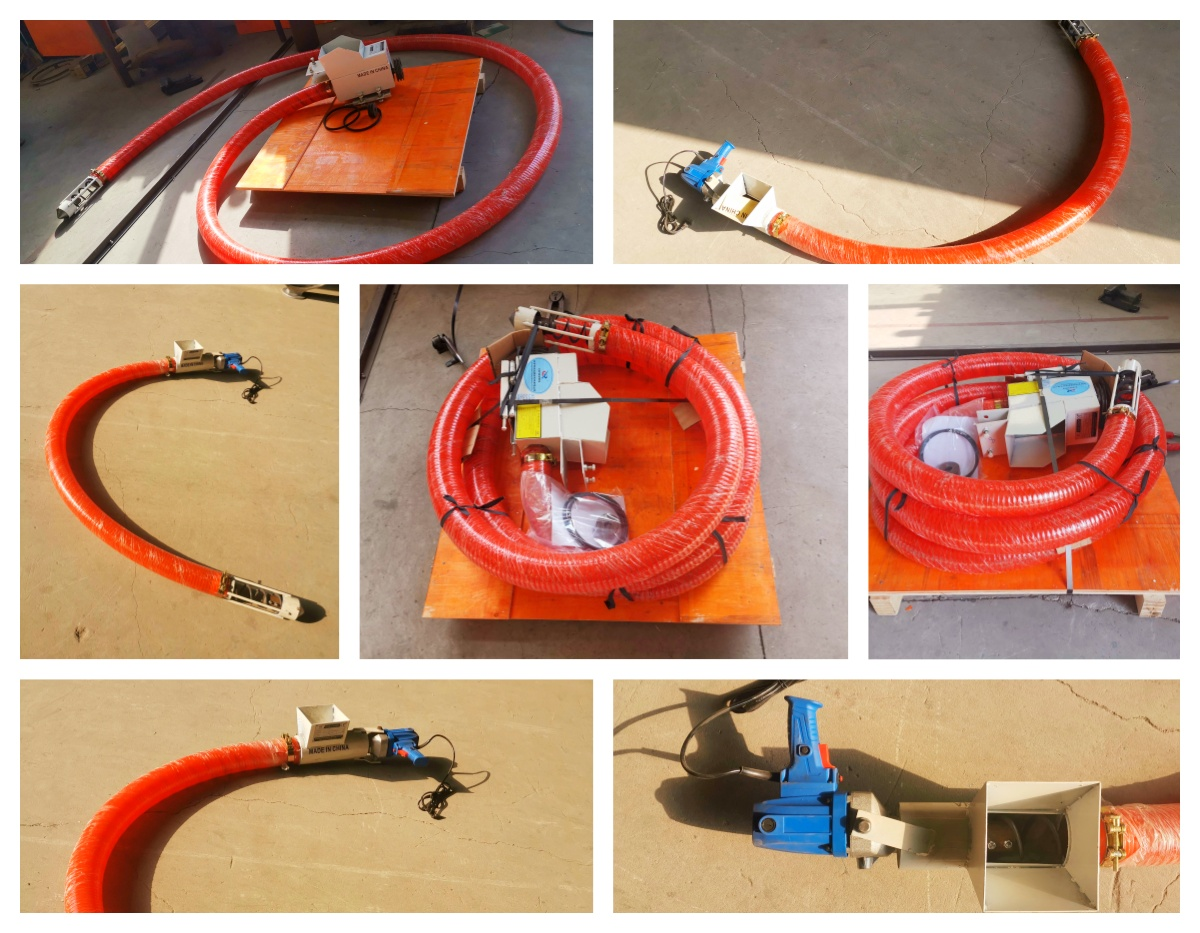

Grain suction machine hose power units typically utilize electric motors, gasoline engines, diesel engines, and other sources to power the suction machine. The spiral mechanism typically utilizes a shaftless coil spring made of manganese steel, which offers excellent hardness and elasticity. The outer edge undergoes special treatment for a smooth finish that will not damage the pipeline. Conveying pipelines often utilize tendon tubing, steel wire tubing, or high-strength PVC hoses, which are cold-resistant, corrosion-resistant, wear-resistant, and impact-resistant. They can be bent freely, making them convenient for use in various locations and environments. The head and tail are user-friendly, ensuring easy operation and connection. The head generally features an inlet, while the tail connects to the power unit and outlet.

What are the advantages of a grain suction machine hose?

The Grain Suction Machine Hose can quickly transport grain from one location to another, reaching several or even dozens of tons per hour. This minimizes grain breakage during transportation, ensuring its quality and integrity. Suitable for transporting grains such as wheat, corn, soybeans, rice, and sorghum, it can also be used to transport hard, non-breakable materials like chemical pellets and plastic granules. Its compact size, lightweight, and flexible top make it easy to move and carry, making it convenient for use in warehouses, loading and unloading areas, and stacking. It can be flexibly adapted to various workspaces, such as farms, grain depots, and docks.

Common grains and recommended mesh for grain suction machine hose

The following is the mesh recommendation for common grains:

Rice: The particle size is about 2-5mm, and a 20-40 mesh screen is recommended. It can effectively filter husks and fine particles while avoiding clogging.

Corn: The diameter is about 4-8mm, and a 10-30 mesh screen is recommended. As the corn particles increase, the mesh aperture can be slightly larger to ensure the consistency of the pipeline.

Wheat: The diameter is about 2-4mm, and a 30-50 mesh screen is recommended. Wheat has higher requirements for cleanliness and needs to be filtered finer.

Soybean: The diameter is about 3-6mm, and a 20-40 mesh screen is recommended to balance efficiency and individual filtration.

Other materials (such as plastic particles, sand and gravel): According to the particle selection, plastic particles usually use 40-80 mesh, and sand and gravel may require 10-20 mesh.

|

Purpose of use |

Recommended mesh range |

Description |

|

Coarse filtration (prevent stones and foreign objects) |

5 mesh~10 mesh |

Applicable to the grain suction port to prevent large debris from entering the pipeline |

|

Medium filtration (prevent small impurities) |

20 mesh~40 mesh |

Prevent small stones, straw segments and other impurities |

|

Dust filtration (end dust removal) |

80 mesh~120 mesh |

Mostly used at the front end of the fan or dust removal device to protect equipment |

Application of grain suction machine hose

Farm operation: In the farm, it can be used to transport grain harvested from the field to the warehouse for storage, or to transport grain in the warehouse to the transport vehicle for convenient transportation to the market or processing plant.

Grain warehouse management: Grain suction machine is suitable for grain warehouse replenishment, warehouse discharge, warehouse turnover, stacking and other operations, to achieve efficient handling and storage management of grain.

Wharf loading and unloading: At the dock, the grain on the ship can be quickly unloaded to the warehouse or transport vehicle on the shore, and the grain in the warehouse can also be loaded on the ship to improve the loading and unloading efficiency of the dock.

Grain processing industry: In flour mills, rice mills, feed mills and other grain processing enterprises, it is used to transport grain from the raw material warehouse to the processing equipment to realize the automated production process.

Selection recommendation of grain suction machine hose

Transportation volume: According to the actual production needs, determine the amount of grain that needs to be transported per hour. Small farms or processing enterprises may need to transport several tons of grain per hour, while large grain warehouses or docks need to transport tens or even hundreds of tons per hour. The conveying capacity of common grain suction machines hose ranges from 3-5 tons to 50-100 tons per hour. The appropriate model can be selected according to the specific output.

Conveying distance: Consider the horizontal distance and vertical height of the suction machine from the feeding point to the discharging point. The horizontal conveying distance generally ranges from tens of meters to hundreds of meters, and the vertical lifting height is usually from a few meters to more than ten meters. If the conveying distance is long or the lifting height is high, it is necessary to select a grain suction machine hose with higher power and stronger conveying capacity to ensure that the grain can be smoothly conveyed.

Grain characteristics: The particle size, shape, density, humidity and other characteristics of different grains will affect the selection of suction machines. For example, corn grains are larger, so it is necessary to select a grain suction machine hose with a larger diameter of the feed port and conveying pipeline; while for grains with higher humidity such as rice, it may be necessary to consider the anti-blocking and moisture-proof performance of the suction machine.