Particle suction conveyor

The particle suction conveyor is a material conveying device that operates based on the negative pressure suction principle and is primarily used for transporting granular, powdered, or small bulk materials.

Capacity: 50 tons/hour

Conveying distance: 30 meters

Pipe diameter: 150 mm

Applicable materials: Powders and granules

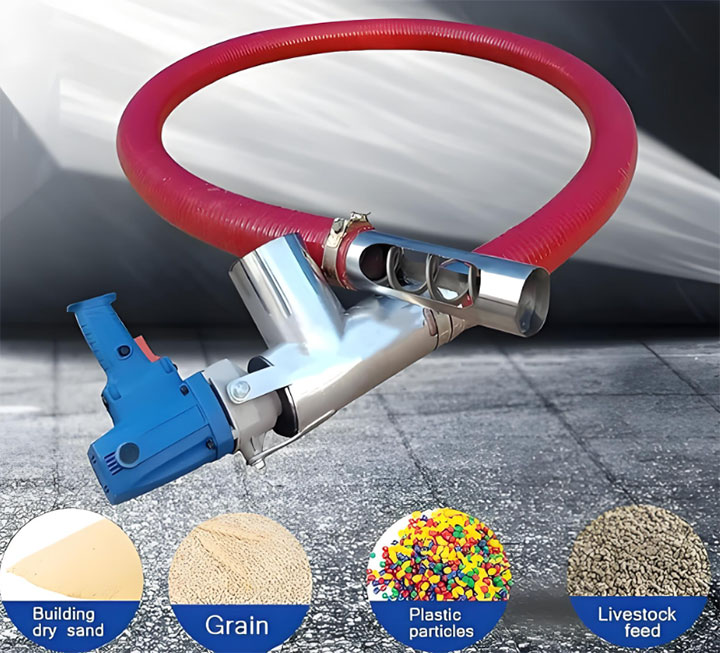

The Particle suction conveyor prevents dust, moisture, and contamination from materials. Its flexible piping layout accommodates complex plant spaces and requires minimal floor space. It is used in industries such as grain processing, plastics manufacturing, chemicals, building materials, and pharmaceuticals, and is particularly well-suited for conveying granular materials over short to medium distances, with multiple unloading points, or requiring high cleanliness.

What is a particle suction conveyor?

The particle suction conveyor is available in various configurations, including handheld, stand-mounted, and mobile truck-mounted. It is suitable for conveying a variety of dry powdered, granular, and small bulk materials. Common applications include cement, flour, feed, plastic pellets, chemical powders, and pharmaceutical raw materials.

Particle suction conveyors offer a wide range of conveying capacities, from small systems capable of 1-5 tons/hour, to medium-sized systems 5-20 tons/hour, and large industrial systems capable of reaching over 50 tons/hour. Standard pipe diameters range from 50mm to 200mm, allowing for flexible selection based on conveying capacity. Typical horizontal conveying distances range from 10-100 meters, with vertical lift heights up to 30 meters. Pricing varies significantly depending on configuration, with basic systems starting at approximately $15,000, standard industrial systems ranging from $30,000 to $80,000, and large, customized systems exceeding $200,000.

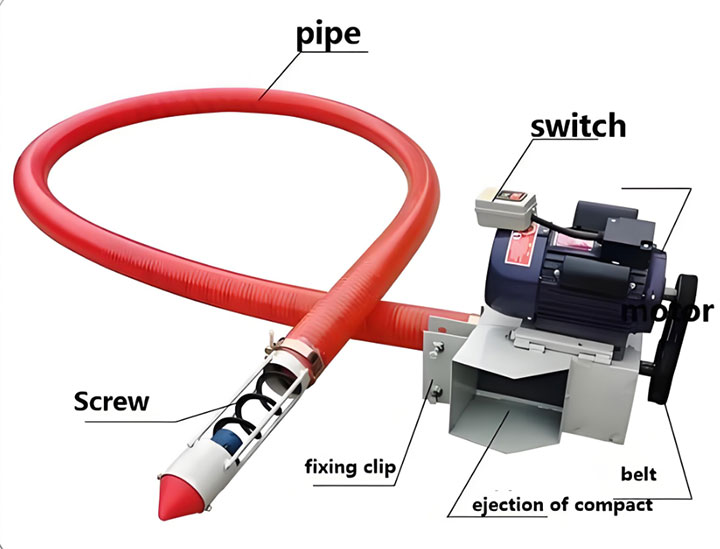

How Particle Suction Conveyors Work

The core structure of a particle suction conveyor consists of a vacuum pump, a separation filter, conveying piping, a suction nozzle, and an electronic control system. Its operating principle is based on negative pressure pneumatic conveying: the vacuum pump generates negative pressure airflow within the system, which draws material through the suction nozzle into the conveying piping, creating a mixed flow of material and air. After the mixed flow enters the separator, the material is separated from the air by gravity. The clean air is discharged through a filter and a vacuum pump, while the material falls into a designated container through a rotary discharge valve. The entire process is completed in a sealed environment, effectively preventing dust leakage.

Particle suction conveyor operation site

Particle suction conveyor advantages

Advantages of the particle suction conveyor: Material compatibility, leak-proof sealing, high-efficiency filtration, and modular design, allowing for flexible adaptation to various production environments.

Material advantages: Specialized materials such as food-grade or corrosion-resistant stainless steel can be selected based on the characteristics of the conveyed material (such as food particles or corrosive particles) to ensure compatibility and safety.

Sealing advantages: Excellent sealing performance effectively prevents material leakage, waste, and environmental pollution, while also preventing the ingress of outside air, ensuring stable conveying. It is particularly suitable for toxic and hazardous materials.

Filtration advantages: Equipped with a high-efficiency filter, it reliably captures impurities in the material, with high filtration accuracy and easy maintenance, preventing environmental contamination and ensuring the purity of subsequent production processes.

Design Advantages: The modular design allows for flexible adjustment of conveying distance and angle (0-90°) based on actual production needs, easily adapting to complex factory layouts and offering strong scalability.

Particle suction conveyor specifications

| Tube diameter | length | Voltage | Power | Effectiveness | Weight |

| 100mm | 3 m | 220V | 3KW | 5-6 t | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6t | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6t | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6t | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6t | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6t | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6t | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6t | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6t | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6t | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8t | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8t | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8t | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8t | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8t | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8t | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8t | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8t | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8t | 89kg |

| 120mm | 12m | 380V | 4KW | 7-8t | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6t | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6t | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7t | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7t | 200kg |

Particle suction conveyor price

The price of a particle suction conveyor varies significantly depending on the type, specifications, material, and function. Small, simple models are suitable for conveying small amounts of particles, such as in home applications, and cost approximately $100-500. Standard industrial-grade equipment, mostly made of carbon steel, offers medium conveying capacity and is commonly used for general factory material handling, with prices ranging from $500-2000. For industries with strict hygiene requirements, such as food and pharmaceuticals, stainless steel particle suction conveyors are often used, with prices ranging from $2000-6000. Large, high-capacity, high-end equipment equipped with intelligent control systems often costs over $10,000 and is suitable for large-scale, highly automated production environments.

Particle suction conveyor supplier

Our factory has extensive experience in manufacturing particle suction conveyors. We can flexibly customize them to meet customer requirements for pipe diameter, conveying distance, and conveying capacity, and even offer trial runs with materials. Targeted at industries like food and pharmaceuticals, we use materials such as stainless steel that meet hygiene standards and conduct rigorous testing to ensure the safety and durability of our equipment. We also provide comprehensive after-sales services, including on-site installation and commissioning, operator training, regular maintenance, and troubleshooting, ensuring stable operation and peace of mind for our customers.