Spring screw conveyor

A spring screw conveyor is a conveying device that uses a coiled spring rotating within a flexible tube to propel materials.

Conveying capacity: 10-50 m³/h

Screw speed: 60-120 rpm

Conveying angle: 0-30°

Applicable materials: Powders/granular materials

Material: Carbon steel/Stainless steel

Spring screw conveyors can stably convey bulk materials such as powders and granular materials, making them suitable for a variety of applications such as cement and grain handling. They are also easy to maintain and highly adaptable to bulk material handling.

What is a spring screw conveyor?

Spring screw conveyors can be used to convey powders, granular materials, or bulk materials. Depending on the characteristics of the conveyed material, they are available in hose and stainless steel versions. Hoses are used for conveying grain, while stainless steel is used for conveying corrosive materials or materials requiring high hygiene requirements. Conveying capacities typically range from 0.5 to 50 cubic meters per hour, with specific values varying depending on the equipment model, material characteristics, and conveying conditions. Conveying speeds are generally controlled between 10 and 50 rpm. When conveying horizontally, the conveying length can generally reach 4-15 meters. When conveying vertically, the conveying length is usually within 1-5 meters. For longer distances, multiple units can be connected in series. The conveying angle is usually no more than 30 degrees. As the angle increases, the conveying capacity decreases accordingly.

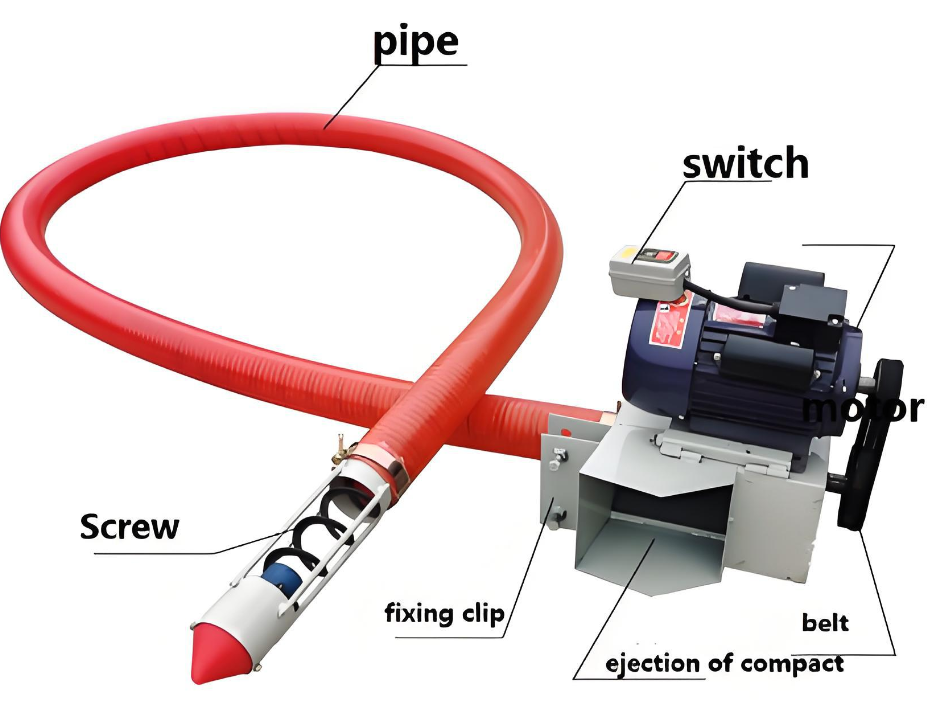

Spring Screw Conveyor Components

The main components of a spring screw conveyor include the drive unit, coiled spring blades, conveying pipe, inlet, outlet, and bracket. The drive unit, consisting of a motor, reducer, and coupling, provides power and controls the speed of the coiled spring blades. The coiled spring blades are the core working component, and their shape and size are designed according to the characteristics of the conveyed material. Hose-type conveyors often have blades integrally molded with the hose, while stainless steel conveyors use blades made of corrosion-resistant materials. The conveying pipe, serving as the material passage, is made of wear-resistant rubber or plastic for hose-type conveyors and 304 or 316 stainless steel for stainless steel conveyors. The inlet and outlet must be compatible with upstream and downstream equipment to ensure smooth material flow. The bracket supports the conveyor and ensures stability during operation.

Spring Screw Conveyor Specifications

| Tube diameter | length | Voltage | Power | Effectiveness | Weight |

| 100mm | 3 m | 220V | 3KW | 5-6 t | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6t | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6t | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6t | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6t | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6t | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6t | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6t | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6t | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6t | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8t | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8t | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8t | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8t | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8t | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8t | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8t | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8t | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8t | 89kg |

| 120mm | 12m | 380V | 4KW | 7-8t | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6t | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6t | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7t | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7t | 200kg |

Spring Screw Conveyor Types

Spring screw conveyors mainly come in the following types: Based on material, they can be categorized as hose-type or stainless steel. Hose-type conveyors are suitable for non-corrosive granular materials, while stainless steel conveyors are suitable for corrosive materials and applications requiring high hygiene. Based on conveying direction, they can be categorized as horizontal, vertical, and inclined. Horizontal conveyors are the most widely used. Vertical conveyors are suitable for lifting materials over short distances, while inclined conveyors are used for both horizontal and vertical conveying, with adjustable tilt angles. Additionally, there are mobile spring screw conveyors equipped with wheels for easy movement between locations, enhancing their flexibility.

Spring Screw Conveyor Price

The price of a spring screw conveyor varies significantly depending on the model, material, specifications, and manufacturer. Small hose-type spring screw conveyors typically cost between $800 and $2,000 and are suitable for small-scale applications such as conveying grain. Medium-sized stainless steel conveyors typically cost between $3,000 and $6,000 and are suitable for conveying medium-volume corrosive materials or materials requiring high hygiene standards. Large, customized spring screw conveyors, such as those used for long-distance transport or specialized applications, can cost anywhere from $70,000 to $12,000. These devices typically require specialized design and manufacturing based on specific conveying parameters.

What are spring screw conveyors suitable for?

Spring screw conveyors have a wide range of applications. For example, in agriculture, spring screw conveyors are commonly used to transport agricultural products such as grains, beans, and feed. Hose-type conveyors, due to their lightness and flexibility, are particularly suitable for small farms and grain processing plants. In the food processing industry, stainless steel spring screw conveyors can be used to transport powdered ingredients such as flour, sugar, and starch, as well as granular foods such as chocolate chips and nuts, meeting food hygiene standards. In the chemical industry, they can transport corrosive or potentially polluting materials such as fertilizers, plastic pellets, and pigments. The sealed conveying pipelines effectively prevent material leakage and environmental pollution. In the construction industry, they can be used to transport building materials such as cement, lime, and sand and gravel, making them particularly suitable for small mixing plants and construction sites. Furthermore, spring screw conveyors play a variety of roles in the pharmaceutical and mining industries, providing solutions for conveying a variety of materials.

Spring Screw Conveyor Operating Principle

The operating principle of a spring screw conveyor is based on the rotation of a spiral blade. The device primarily consists of a drive unit, spiral blades, conveying pipes, and inlet and outlet ports. As the drive unit rotates the spiral blades, the blades generate thrust, enabling the material to overcome gravity and pipe friction, moving along the conveying pipe from the inlet to the outlet. The direction of material conveyance is determined by the blade rotation and direction of rotation. Adjusting the drive unit speed controls the conveying volume and speed. This device can convey materials within a closed pipe, minimizing material flight and environmental pollution.

Spring Screw Conveyor Customer Site