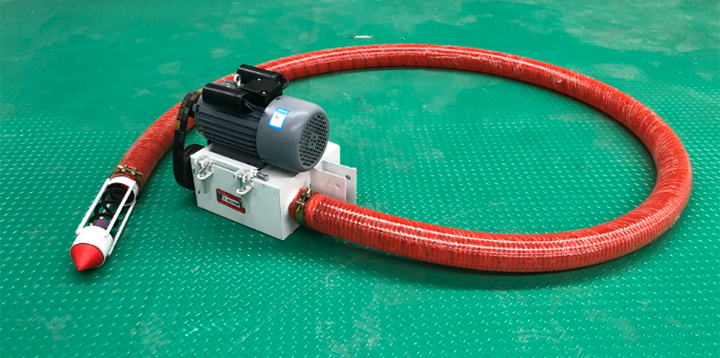

Aggregate hose screw conveyor

Wednesday January-14 2026 17:01:58

Aggregate hose screw conveyor transports aggregates to mixing plants, trucks, and other locations via a flexible hose. Depending on the screw diameter and rotational speed, the conveying capacity typically ranges from 10 to 150 m³/h. This equipment can transport aggregates with a particle size range of 0–40 mm; smaller sizes are better suited for fine sand and small-particle aggregates, while larger sizes can stably transport medium-sized crushed stone. The entire machine is primarily constructed of high-strength carbon steel, stainless steel, or wear-resistant alloy steel. The screw blades and inner wall of the pipe can be treated for wear resistance depending on the operating conditions to accommodate the highly abrasive nature of the aggregates. It can transport natural sand, crushed stone, small-particle ores, and other granular or powdery aggregates.

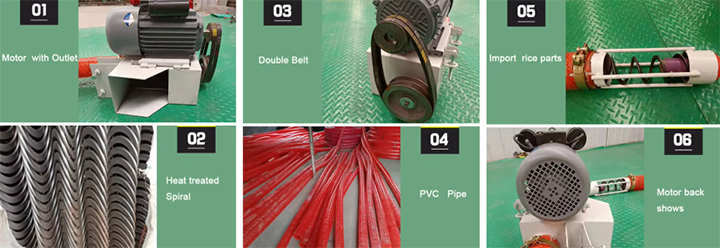

Aggregate Hose Screw Conveyor Structure

The aggregate hose screw conveyor consists of a drive unit, screw shaft, screw blades, flexible or semi-rigid pipe, inlet, outlet, and support and sealing components. The equipment uses a motor to drive the screw shaft, causing the aggregates to be continuously conveyed forward along the pipe. For granular materials such as sand and gravel, the spiral blades are generally thickened, and the blade pitch is optimized to minimize material breakage and blockage while ensuring conveying efficiency. The inside of the pipe is usually equipped with replaceable wear-resistant bushings or rubber linings to improve wear resistance and extend the equipment's service life. Furthermore, a suitable gap is maintained between the spiral blades and the pipe wall to balance conveying stability and anti-jamming performance.

Features of Aggregate Hose Screw Conveyors

Aggregate hose screw conveyors have a sealed pipe diameter, minimizing material leakage and dust generation during aggregate conveying. The equipment is highly wear-resistant and durable; key components in contact with the material are made of wear-resistant materials. The spiral blades typically have a lifespan of 8000–12000 hours, and the liner life is approximately 10000–15000 hours, making it suitable for operation conditions exceeding 3200 hours per year with a low failure rate. The equipment supports tilting conveying from 0-60° and can be adapted to different granular materials by changing the blade type. A single unit can meet the transfer needs of multiple scenarios, and the tilting conveying efficiency is 20%-30% higher than traditional equipment. Compared to belt conveyors, the Aggregate Hose Screw Conveyor has a smaller footprint, making it suitable for factories with limited space.

Aggregate Hose Screw Conveyor Size Chart

| Model | Outer Diameter (mm) | Inner Diameter (mm) | Conveying Capacity (m³/h) | Conveying Particle Size (mm) | Typical Motor Power (kW) |

| AHC-50 | 50 | ~42 | 0.2 - 0.5 | ≤5 | 0.18 - 0.37 |

| AHC-75 | 75 | ~66 | 0.5 - 1.5 | ≤6 | 0.37 - 0.75 |

| AHC-90 | 90 | ~80 | 1.2 - 2.5 | ≤8 | 0.75 - 1.5 |

| AHC-110 | 110 | ~100 | 2.5 - 4.5 | ≤10 | 1.5 - 3.0 |

| AHC-130 | 130 | ~120 | 4.0 - 6.5 | ≤12 | 2.2 - 4.0 |

| AHC-150 | 150 | ~140 | 6.0 - 8.5 | ≤15 | 3.0 - 5.5 |

| AHC-180 | 180 | ~165 | 8.0 - 12.0 | ≤18 | 4.0 - 7.5 |

| AHC-200 | 200 | ~185 | 10 - 15 | ≤20 | 5.5 - 11 |

Aggregate Hose Screw Conveyor Price

The price of an Aggregate Hose Screw Conveyor is affected by factors such as pipe diameter, length, material, drive power, and wear-resistant configuration. Small equipment with a pipe diameter of φ160–φ200 mm typically costs around $2,000–$4,000. Medium-sized equipment, mostly with a pipe diameter of φ250–φ300 mm, offers higher conveying capacity and stability, suitable for most sand and gravel production lines, and its price range is approximately $4,000–$6,000. For large equipment with a diameter of φ350 mm and above, if equipped with a high-power drive, motor reduction system, and wear-resistant bushings or thickened spiral blades, the price generally ranges from $7,000 to $12,000.

Aggregate Hose Screw Conveyor Manufacturers

Manufacturers of aggregate hose screw conveyors are located in Germany, the United States, China, and other countries. Dahan Machinery, in particular, has extensive experience in aggregate conveying and bulk material handling, and can provide standardized products as well as customized solutions. For example, they can customize the pipe material, spiral blade width, and pipe diameter range according to the wear resistance of the aggregate. This provides a reliable solution for aggregate conveying.

Applications of Aggregate Hose Screw Conveyors

Aggregate hose screw conveyors can be used for conveying aggregates from storage bins to batching systems, and can also be used for transferring finished aggregates after crushing and screening. In concrete mixing plants, it enables the continuous, quantitative supply of sand and gravel aggregates; in asphalt mixing plants, it is used for the closed conveying of aggregates, reducing dust pollution; in mines and aggregate plants, it can serve as a short- or medium-distance aggregate transfer device, complementing other conveying methods.

The aggregate hose screw conveyor takes into account the particle characteristics and wear features of sand and gravel aggregates in its structure, materials, and wear resistance, reducing maintenance costs while ensuring conveying efficiency. By rationally selecting pipe diameters and configurations, it can meet the conveying needs of aggregates with different particle sizes and production capacities. With its stable and reliable performance and good adaptability, the aggregate hose screw conveyor has become an indispensable piece of equipment in aggregate processing and building material production lines.