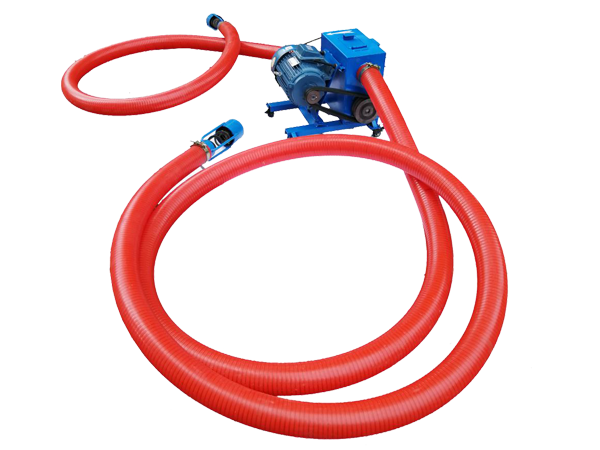

Biomass Pellet Flexible Screw Conveyor

Monday January-19 2026 16:39:01

Biomass Pellet Flexible Screw Conveyor reduces material breakage and spillage during biomass pellet conveying. The machine uses wear-resistant steel or has a surface coating to resist biomass pellet wear. Different pipe diameters are available, including Φ65mm, Φ89mm, Φ114mm, and Φ150mm, with a typical single-unit conveying length of 30 meters. It can convey 3-35 tons of biomass pellets per hour.

Biomass Pellet Flexible Screw Conveyor Parts

The Biomass Pellet Flexible Screw Conveyor consists of a screw shaft, conveying pipe, motor, and inlet/outlet ports. The screw shaft uses a high-hardness alloy coating process, and the conveying pipe is made of wear-resistant polymer material, which can withstand continuous friction from biomass pellets, extending its service life by more than 50% compared to ordinary parts. The inner wall of the conveying pipe is mirror-polished, and the screw blades feature an optimized arc design to avoid pellet collision and compression, reducing breakage and dust generation, and ensuring pellet integrity. The components feature a modular assembly structure, allowing for free adjustment of the conveying direction and length to adapt to different layouts in biomass production lines.

Benefits of the Biomass Pellet Flexible Screw Conveyor

The Biomass Pellet Flexible Screw Conveyor is a shaftless screw conveyor. Without a central shaft within the pipe, it can convey more biomass pellets without clogging. The flexible screw rotates at low speed within the flexible pipe, propelling the material through sliding rather than grinding, preventing compression of the biomass pellets and reducing breakage. The dust generated during biomass pellet conveying is wasteful, combustible, and poses an explosion risk, while also polluting the workshop environment. The machine's sealed pipes prevent biomass dust from escaping.

Biomass Pellet Flexible Screw Conveyor Specifications

| Pipe Diameter (mm) | Horizontal Conveying Capacity (m³/h) | Inclined Conveying Capacity (m³/h) | Vertical Conveying Capacity (m³/h) |

|---|---|---|---|

| 63 | 3-6 | 2-4 | 1-2 |

| 89 | 6-10 | 4-8 | 2-4 |

| 110 | 10-14 | 7-11 | 3-6 |

| 125 | 12-18 | 8-14 | 4-7 |

| 150 | 15-22 | 10-17 | 5-9 |

| 200 | 25-35 | 18-28 | 8-14 |

Biomass Pellet Flexible Screw Conveyor Price

For smaller machines made of carbon steel and 3-5 meters in length, the Biomass Pellet Flexible Screw Conveyor is priced between $1,200 and $2,800. For medium-sized equipment with wear-resistant treatment of key components and a conveyor length of 6-10 meters, the price range is $3,200 - $5,300. The price depends on the conveyor length, material, motor type, and other configurations. For example, explosion-proof motors are more expensive than ordinary motors, and stainless steel screws are more expensive than carbon steel screws. A quote can be obtained based on actual production capacity needs, conveying distance, and operating conditions.

Biomass Pellet Flexible Screw Conveyor Manufacturers

Biomass Pellet Flexible Screw Conveyor manufacturers are located in Europe, America, and China. European manufacturers possess sophisticated technology, producing wear-resistant, well-sealed products with high levels of automation integration. Chinese manufacturers can quickly respond to customers' non-standard customization needs. For example, Dahan Machinery can recommend suitable models or customize products based on the machine's material, pipe diameter, and pipe length, offering better value for money. When choosing, select the appropriate manufacturer based on your machine requirements.

Biomass Pellet Flexible Screw Conveyor Use Case

A biomass energy plant previously used traditional rigid conveyors to transport wood pellets, which easily led to jamming, machine failure, and material crushing. Furthermore, these conveyors had to be installed in a straight line, making them unsuitable for complex plant layouts. After switching to the Biomass Pellet Flexible Screw Conveyor, conveying efficiency improved by 15%-30%. By adjusting the motor speed to control the conveying volume, the material breakage rate was reduced. The equipment can bend to avoid obstacles, and its enclosed conveyor design reduces dust spillage. The absence of additional moving parts eliminates the risk of lubricant contamination, ensuring the purity and combustion efficiency of the biomass pellets.

The Biomass Pellet Flexible Screw Conveyor can be used in biomass pellet plants, small to medium-sized biomass boiler rooms, pellet fuel production lines, and other scenarios. It can be used when transporting biomass pellets from trucks to indoor areas or from lower to higher silos. Moreover, it is relatively easy to install and can supply materials in small batches at multiple points, making it a lightweight piece of equipment for frequently transporting biomass pellets.