Bulk powder Flexible Screw Conveyor

Saturday January-10 2026 17:02:51

Bulk powder Flexible Screw Conveyor is a flexible metal auger placed inside a flexible pipe. A drive unit rotates the auger, propelling the bulk powder along the pipe. The pipe diameter is selected based on conveying requirements, with common diameters including 40mm, 100mm, 120mm, and 150mm. Standard single-unit lengths typically range from 2 to 10 meters, but through combination, the maximum conveying distance can reach 20 meters or even further. Smaller models can handle 3-4 tons per hour, while industrial-grade models can reach up to 20 tons per hour. The flexible outer tube is often made of wear-resistant, cold-resistant rubber or polyethylene, while the auger blades are commonly made of stainless steel. The surfaces in contact with the material are polished for corrosion resistance and easy cleaning.

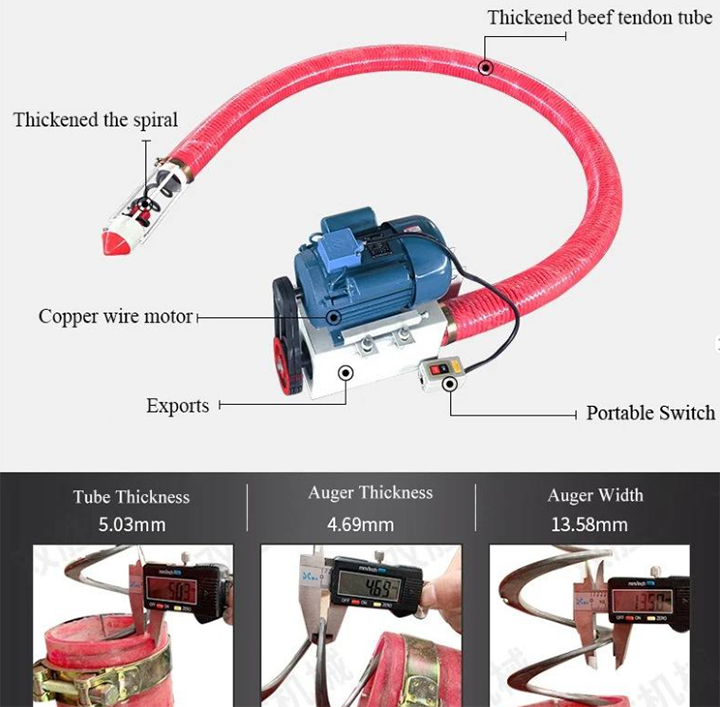

Bulk Powder Flexible Screw Conveyor Structure

The Bulk Powder Flexible Screw Conveyor consists of a flexible outer tube, auger blades, a drive motor, and feeding/discharging devices. During installation, simply fix the drive unit to the discharge or feed end and lay the flexible pipeline on the preset path. No complex support structure or precise straight alignment is required, and it can be arranged in a curved manner to bypass obstacles. During operation, the motor drives the spiral blades to rotate, which continuously pushes the bulk powder forward until it is output from the discharge port.

Advantages of the Bulk Powder Flexible Screw Conveyor

The Bulk Powder Flexible Screw Conveyor offers five advantages for conveying bulk powder, making it widely used in powder transport.

Bulk powders often have poor flowability and are prone to bridging or arching. The Bulk Powder Flexible Screw Conveyor contains only a single spiral spring made of stainless steel. As the spiral rotates, the absence of intermediate bearings or suspension supports to obstruct material flow makes it suitable for conveying viscous, easily agglomerated, or high-moisture powders.

The Bulk Powder Flexible Screw Conveyor can convey bulk powder along vertical, horizontal, and even inclined curved paths. It can easily bypass pipes, beams, or other equipment, directly transporting powder from point A to point B without complex intermediate transfer points.

Some bulk powders are mixtures, and in traditional conveying, lighter powders and heavier particles easily separate. The flexible screw conveyor causes slight tumbling of the powder during transport. This not only prevents material separation but also remixes the powder, resulting in a more uniform composition.

Bulk powder conveying easily generates dust, causing product loss, harming worker health, and potentially leading to cross-contamination. The Bulk Powder Flexible Screw Conveyor is a closed pipe; material is transported within a closed tube, preventing external air from entering and internal dust from escaping.

The feed inlet of the flexible screw conveyor can be located anywhere in the tube as needed, facilitating powder collection from multiple sources. Compared to bucket elevators or belt conveyors, the flexible screw conveyor has a smaller footprint, can be directly installed between existing equipment, and has lower investment costs.

Bulk Powder Flexible Screw Conveyor Parameters

| Parameter Category | Parameter Range |

| Pipe Diameter (mm) | 40 / 50 / 65 / 75 / 90 / 110 / 130 |

| Conveying Capacity (m³/h) | 0.2 – 25 |

| Conveying Distance (m) |

Horizontal: 2 – 20 Vertical: 2 – 8 |

| Working Pressure (MPa) | ≤ 0.3 (Low pressure or micro-pressure) |

| Hose Material | Food-grade PU / Industrial-grade PU / Rubber composite tube |

| Hose Service Life | 1 – 5 years |

| Screw Material | Spring steel / Stainless steel (304/316) |

| Screw Rotating Speed (rpm) | 300 – 1400 |

| Driving Power (kW) | 0.75 – 11 |

| Conveying Angle | 0° – 90° |

| Working Temperature (℃) | -10 ~ +60 (Standard PU) |

Bulk Powder Flexible Screw Conveyor Types

For different applications, two types of Bulk Powder Flexible Screw Conveyors are available: a handheld type and a motor-driven type.

The handheld type is lightweight and can be equipped with casters or held directly by hand. It is typically equipped with a pneumatic motor or a small motor and can be used for transferring materials between multiple hoppers in a workshop, transferring small batches, or in situations requiring frequent relocation due to space constraints. Its conveying capacity is typically 3-4 tons/hour.

The stationary motor type can be mounted on a fixed bracket or placed on the ground. It can be configured with single-phase electricity, three-phase electricity, diesel engine, or gasoline engine drive, depending on the power supply available. The machine is powerful, with a conveying capacity of 4-20 tons/hour, suitable for continuous, long-term operations in factory production lines, large silos, and other similar scenarios.

Bulk Powder Flexible Screw Conveyor Application Cases

An agricultural powder manufacturer faced severe dust pollution and cumbersome maintenance issues with traditional conveying equipment. By adopting three Bulk Powder Flexible Screw Conveyors, they transported flour from outdoor silos to indoor mixers. Two models combined achieved a conveying capacity of 40t/h over a distance of 5.5 meters, while the third conveyed at a 60° angle over a distance of 6 meters, resolving dust leakage and unplanned downtime issues.

A nutritional supplement company replaced manual high-altitude feeding with two mobile Bulk Powder Flexible Screw Conveyors, conveying 25 kg packages of chocolate powder from a ground-level hopper to a sieving machine above the mixer over a distance of 7.5 meters. This not only avoided dust pollution but also improved operational safety and production efficiency.

Bulk powder flexible screw conveyors can transport bulk powders such as flour, milk powder, flavoring powder, pigment powder, zinc oxide, carbon black, lime powder, and refractory materials. It can transport not only free-flowing powders and lightweight, loose powders, but also viscous powders with a certain degree of moisture. The machine is easy to maintain, relatively low in cost, and flexible in layout. Because the conveying pipeline is enclosed, it solves the dust problem during powder conveying, protects the health of operators, and meets environmental requirements.