Chemical explosion-proof flexible hose screw conveyor

Tuesday January-13 2026 17:06:01

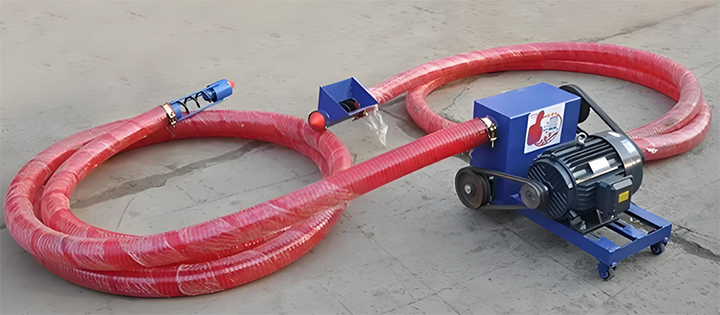

During the conveying of chemical materials, some materials may exhibit flammable or explosive properties, thus requiring a Chemical explosion-proof flexible hose screw conveyor. The machine's motor is an explosion-proof motor, meeting Ex d and other explosion-proof certification standards. The spiral blades are made of stainless steel, and the inner wall of the hose is made of a non-metallic anti-static material, avoiding the risk of explosion. The machine can convey chemical materials at a rate of 0.5-150 m³/h, with a typical conveying length of 1-15 meters and a rotation speed range of 10-150 rpm, adjustable according to the explosion-proof requirements of the material to prevent friction-induced heating.

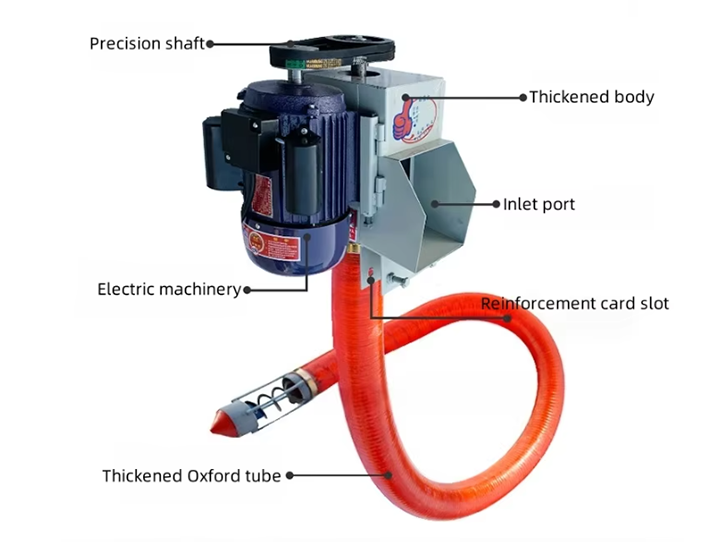

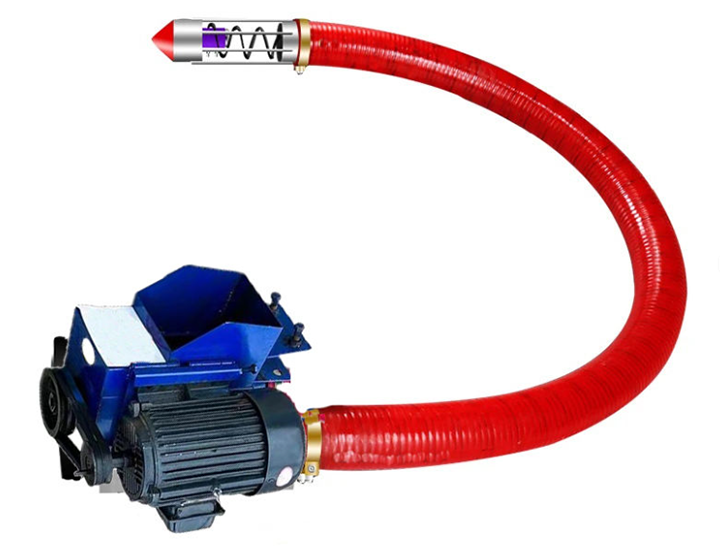

Structure of the Chemical explosion-proof flexible hose screw conveyor

The spiral shaft of the Chemical explosion-proof flexible hose screw conveyor is made of stainless steel to prevent explosions of flammable chemicals during transport. The hose is made of food-grade polyurethane, nylon, or Teflon, with a smooth wall to reduce frictional resistance. The explosion-proof motor used as the drive unit employs an explosion-proof rating such as Ex d IIB T4, sealing potentially spark-generating components within a robust housing and enhancing safety. The feed inlet is typically designed as a bucket-shaped or flanged connection for easy docking with equipment in the preceding process. The discharge port is located at the end of the hose and can be round, square, or equipped with a butterfly valve to control material cutting and flow.

What are the advantages of a chemical explosion-proof flexible hose screw conveyor?

The chemical explosion-proof flexible hose screw conveyor uses an explosion-proof motor, sealing potentially spark-generating components within a robust housing. An appropriate gap exists between the screw and the hose wall, preventing direct metal-to-metal scraping caused by eccentricity or vibration. The pipeline is sealed, preventing combustible dust or vapor from escaping into the surrounding air and creating an explosive atmosphere. The flexible hose is bendable and extendable, bypassing equipment or obstacles without requiring multiple connections, reducing leakage points. Furthermore, compared to rigid pipes, flexible hoses are lighter, reducing installation difficulty and cost. The machine's speed is adjustable, enabling quantitative conveying in different directions. When conveying corrosive media such as acids, alkalis, and organic solvents, the hoses and spiral blades must be made of stainless steel, PTFE coating, or special alloys. For chemical materials prone to static electricity buildup, the machine's conductive hoses are grounded to eliminate the risk of static electricity.

Chemical Explosion-Proof Flexible Hose Screw Conveyor Model List

| Model | Capacity (t/h) | Inner Ø (mm) | Length (m) | Speed (rpm) | Motor (kW) | Explosion-Proof | Material |

| FSHC-80 | 0.5-2.0 | 80 | 5-10 | 1400 | 0.75-1.1 | Ex d IIB T4 | Q235 / SUS304 |

| FSHC-100 | 1.0-3.5 | 100 | 5-15 | 1400 | 1.1-1.5 | Ex d IIB T4 | Q235 / SUS304 |

| FSHC-125 | 2.0-5.0 | 125 | 5-20 | 960 | 1.5-2.2 | Ex d IIB T4 | Q235 / SUS304 |

| FSHC-150 | 3.0-8.0 | 150 | 5-20 | 960 | 2.2-3.7 | Ex d IIB T4 | Q235 / SUS304 |

| FSHC-200 | 6.0-12.0 | 200 | 5-25 | 960 | 3.7-5.5 | Ex d IIB T4 | Q235 / SUS304 |

| FSHC-250 | 10.0-18.0 | 250 | 5-30 | 720 | 5.5-7.5 | Ex d IIB T4 | Q235 / SUS316L |

| FSHC-300 | 15.0-25.0 | 300 | 5-30 | 720 | 7.5-11 | Ex d IIB T4 | Q235 / SUS316L |

Chemical Explosion-Proof Flexible Hose Screw Conveyor Applications

Chemical explosion-proof flexible hose screw conveyors can convey flammable and explosive powders, polymer particles prone to static electricity, materials in environments with volatile organic solvents, and continuous production processes involving Class A explosion-proof areas. For example, conveying pigment pastes containing volatile solvents, and conveying flammable dust such as lithium cobalt oxide and graphite.

Chemical Explosion-Proof Flexible Hose Screw Conveyor Suppliers

For the explosion-proof requirements of the chemical industry, manufacturers of chemical explosion-proof flexible hose screw conveyors produce machines with anti-static structures, and the motors and electrical components are equipped with explosion-proof or dust explosion-proof certifications that comply with ATEX or national standards. Flexible screw conveyors, while being explosion-proof, can be customized in terms of pipe diameter, length, and other requirements to meet the conveying needs of chemical materials.

The price of a chemical explosion-proof flexible hose screw conveyor ranges from approximately $800 to $5000, varying depending on the explosion-proof design, corrosion-resistant materials, and the machine's pipe diameter and length. When selecting a conveyor, you can provide the supplier with information such as the operating environment and conveying capacity so that they can recommend smaller or larger models, or even offer customized solutions.