Chemical powder screw conveyor

Tuesday January-27 2026 17:29:46

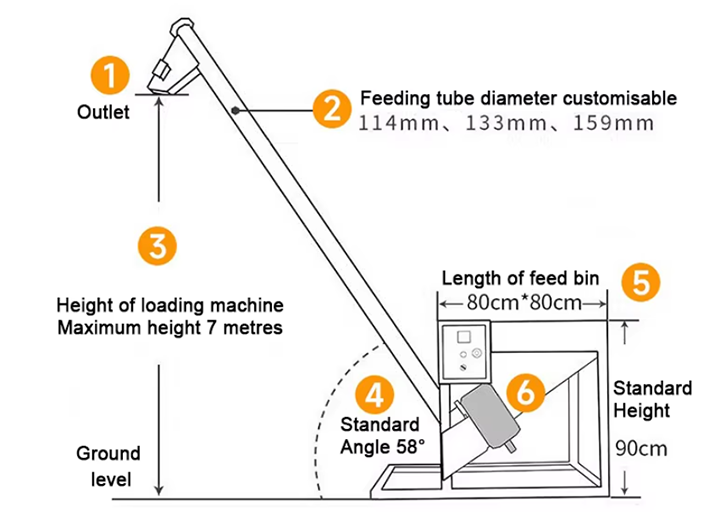

Chemical powder screw conveyor enables the closed, continuous, and quantitative transfer of chemical powders, suitable for scenarios such as raw material storage, high and low level feeding, and inter-process material conveying in chemical production lines. It solves the pain points of conveying chemical powders, including their tendency to generate dust, poor flowability, easy clumping, and some corrosive substances. The conveying capacity can be adjusted according to production line needs, typically adapting to low to medium output conveying from 2 to 15 cubic meters per hour. The lifting angle can achieve horizontal, inclined, and vertical conveying from 0° to 90°, meeting the spatial requirements of different height differences in chemical production lines. The conveying distance can reach 3-15 meters, matching the process layout of most chemical workshops.

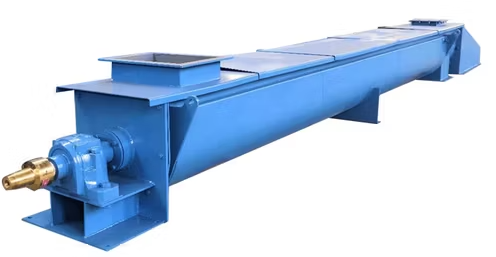

Chemical Powder Screw Conveyor Components

The chemical powder screw conveyor consists of a storage hopper, a feeding adjustment unit, a screw conveyor body, a drive system, a discharge port, and various supporting accessories. When the screw blades rotate, they push the chemical powder forward; the enclosed casing firmly blocks the conveying path, preventing dust from scattering. A motor and reducer provide power to the entire machine. The inlet and outlet handle material input and output, bearings support the rotation of the screw shaft, and sealing devices prevent material leakage. These components work together to ensure stable and safe conveying of chemical powders.

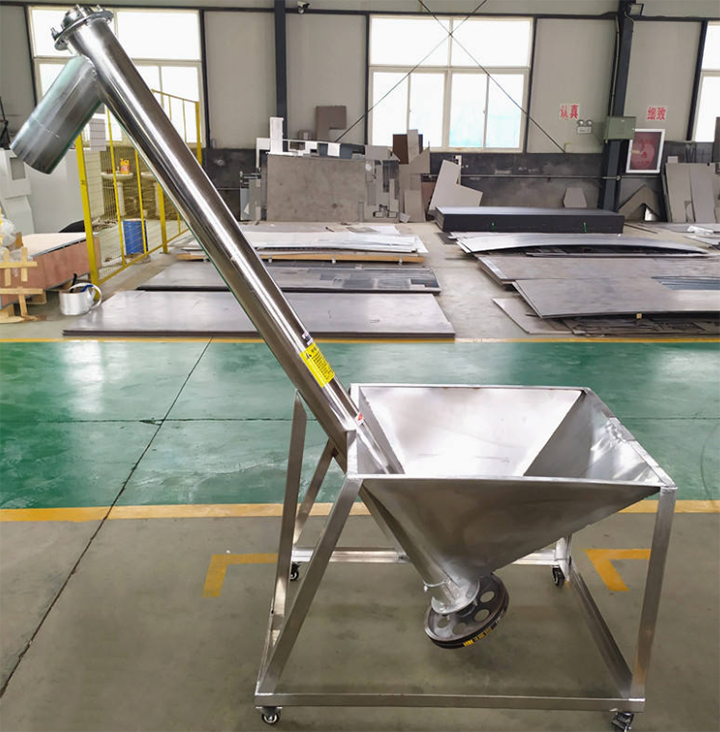

Advantages of Chemical Powder Screw Conveyors

The inner wall of the hopper in a chemical powder screw conveyor is typically polished, and the bottom is usually designed with a conical or arc-shaped discharge port. Some are also equipped with pneumatic anti-bridging devices or vibrators to break up clumps of powder, preventing chemical powder from sticking to the hopper walls and ensuring smooth discharge. The screw conveyor uses rotating helical blades to push material along the cylinder wall, achieving inclined conveying from 0° to 60°, with a height of up to 6 meters, solving material transfer problems between high and low positions on the production line. The blades can be customized according to powder characteristics; for example, full-face blades are suitable for coarse powders with good flowability, while blades with scrapers are suitable for fine powders that easily clump. Various body materials are also available, including stainless steel and rubber-lined carbon steel, capable of handling corrosive or sticky chemical powders.

Chemical Powder Screw Conveyor Parameters

| Parameter | Typical Value |

| Conveying Capacity | 500 – 3000 kg/h |

| Lifting Height | 1.5 – 6.0 m |

| Material Form | Powder / Granule |

| Bulk Density | 0.3 – 1.5 t/m³ |

| Moisture Content | ≤10% |

| Material Temperature | ≤80°C |

| Screw Diameter | Φ100 / Φ160 / Φ200 mm |

| Rotational Speed | 30 – 120 rpm (Frequency Conversion) |

| Material Contact Material | SUS304 (Optional 316L) |

| Surface Treatment | Polishing (Food Grade) |

| Hopper Capacity | 50 – 200 L |

| Motor Power | 1.1 – 4.0 kW |

| Driving Mode | Reduction Motor |

| Control Mode | Frequency Conversion Control |

| Power Supply | 380V / 50Hz / 3P |

| Installation Method | Fixed Type (Base) |

| Cleaning & Maintenance | Detachable Screw |

Chemical Powder Screw Conveyor Price

The price of a chemical powder screw conveyor ranges from approximately $900 to $5000. For example, a unit with a pipe diameter of approximately 200-300mm, a conveyor pipe length of 3-6m, made of 304 stainless steel, and equipped with a vibrating hopper and a speed-regulating motor, would cost around $1200-$3000. The price depends on factors such as screw diameter and load capacity, hopper capacity, and explosion-proof or corrosion-resistant requirements. Carbon steel is the cheapest, 304 stainless steel is moderately priced, and 316L stainless steel is more expensive due to its superior corrosion resistance.

Chemical Powder Screw Conveyor Case Study

On a chemical company's compound fertilizer production line, a chemical powder screw conveyor was used to lift lightweight, dusty potassium carbonate powder from the bottom storage area to the 8-meter-high mixing reactor feeding port. The equipment is equipped with a sealed stainless steel silo, which effectively buffers against fluctuations in material flow from the upstream pneumatic conveying system. The 35-degree inclined shaftless spiral blades, combined with a built-in nitrogen inerting protection system, solve the problems of poor powder flowability and bridging, while ensuring explosion-proof safety. The entire system can achieve continuous conveying of 2.5 tons per hour, with a completely sealed, dust-free process, reducing powder loss by over 95%, improving the workshop environment, and enhancing batching accuracy.

Applications of Chemical Powder Screw Conveyors in the Chemical Industry

Powder screw conveyors are used in the transfer of various chemical raw materials, intermediates, and finished products. They can transport various chemical powders such as soda ash, fertilizers, pigments, rubber additives, plastic particles, and chemical fillers. The equipment can also be used in conjunction with mixers, packaging machines, or storage silos to form a continuous operation process, thereby improving the production efficiency of chemical powders.