Chili Powder Screw Conveyor

Monday January-05 2026 16:49:01

Chili Powder Screw Conveyor transports chili powder from low to high positions. Chili powder is characterized by its fine particles, moderate flowability, tendency to generate dust, slight oiliness, and pungent odor. This conveying system, through a closed, continuous conveying mechanism, solves the problems of dust dispersion, blockage, and material loss that often occur in conventional conveying methods.

The Chili Powder Screw Conveyor is made of food-grade stainless steel, preventing corrosion or residual contamination from the capsaicin in the chili powder. The conveying capacity of the chili powder screw conveyor ranges from 0.5 to 50 cubic meters per hour, depending on the screw diameter, screw speed, filling factor, and conveying angle.

Components of the Chili Powder Screw Conveyor

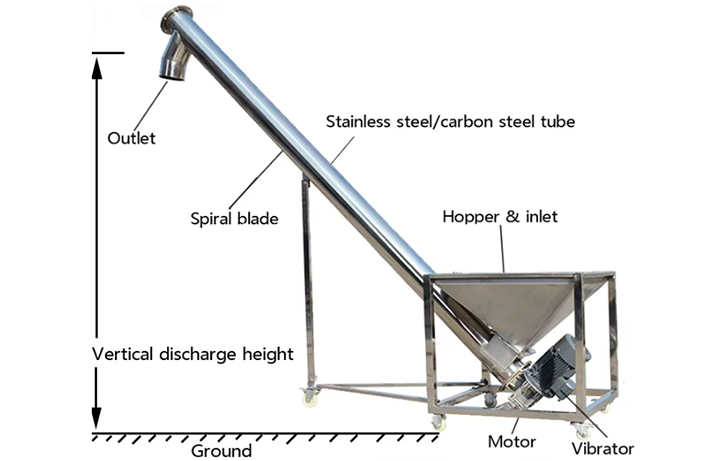

The Chili Powder Screw Conveyor consists of a screw shaft, screw blades, tube body, drive unit, inlet and outlet ports, and sealing system. The screw shaft is made of hollow steel tubing, ensuring strength while reducing weight. The spiral blades are designed based on the characteristics of chili powder, generally using full-surface blades to reduce chili powder residue. For chili powder variants prone to clumping, a strip blade design can be used to prevent excessive compression of the chili powder.

During operation, the motor drives the spiral shaft to rotate, and the spiral blades propel the chili powder axially forward within the enclosed trough. The inlet evenly feeds loose or pulverized chili powder into the trough, and the spiral blades utilize thrust and friction to continuously move the material, ultimately discharging it from the outlet.

Chili Powder Screw Conveyor Functions

The Chili Powder Screw Conveyor enables continuous and uniform conveying, ensuring stable flow of chili powder during ingredient preparation, mixing, or packaging, preventing material interruptions or accumulation. Precise control of the spiral speed via frequency conversion allows for quantitative feeding with an error of less than ±2%. The fully enclosed conveying pipeline effectively suppresses the escape of irritating odors and dust, improving the workshop environment. The equipment can be linked with pulverizers, mixers, and screening equipment to form an automated production line. To address the tendency of chili powder to absorb moisture and clump, optional moisture-proof designs such as polished inner walls and nitrogen protection, or the addition of a vibration-assisted caking device, can be incorporated to improve the continuity and reliability of the conveying process.

Chili Powder Screw Conveyor Specifications

| Item | Parameter Description |

| Equipment Name | Chili Powder Screw Conveyor |

| Applicable Materials | Chili powder, condiments and other food granules |

| Conveying Mode | Screw conveying (horizontal / inclined) |

| Conveying Capacity | 0.5 - 10 T/h (customizable) |

| Conveying Length | ≤ 10 m |

| Screw Diameter | Ø100 / Ø150 / Ø200 / Ø250 / Ø300 mm |

| Rotating Speed | 20 - 120 rpm |

| Motor Power | 0.75 - 7.5 kW |

| Material | SUS304 stainless steel |

| Feeding Mode | Flange feeding |

| Discharging Mode | Flange discharging |

| Power Supply | 380V / 50Hz |

Benefits of the Chili Powder Screw Conveyor

Using the Chili Powder Screw Conveyor to convey chili powder not only reduces the intensity of manual handling and minimizes eye and respiratory irritation from chili powder, but also reduces chili powder loss and secondary contamination. The enclosed structure helps maintain the color, aroma, and spiciness of the chili powder, preventing quality degradation due to moisture or oxidation. The equipment also operates more stably, avoiding reduced chili powder conveying output caused by frequent downtime for maintenance.

Chili Powder Screw Conveyor Applications

The Chili Powder Screw Conveyor is used in chili powder processing, seasoning production, food ingredients, and pre-processing of catering raw materials. From the intermediate conveying of dried chili powder after grinding to the mixing, metering, and packaging processes of the finished chili powder, the screw conveyor performs its conveying function effectively. Furthermore, in the production of compound seasonings, it can be used in conjunction with various powders such as salt, cumin powder, and Sichuan peppercorn powder to ensure accurate formula proportions.

The design and configuration of the Chili Powder Screw Conveyor takes into account the characteristics of chili powder, solving the challenges faced by traditional conveying equipment when handling this special material. This provides referable case studies for various scenarios. For example, chili powder processing plants often use this equipment to convey chili powder to packaging machines, which then package the chili powder for sale. In space-constrained factories, a small-angle inclined conveying angle, typically controlled within 20°, is used to prevent chili powder backflow or reduced filling rate.