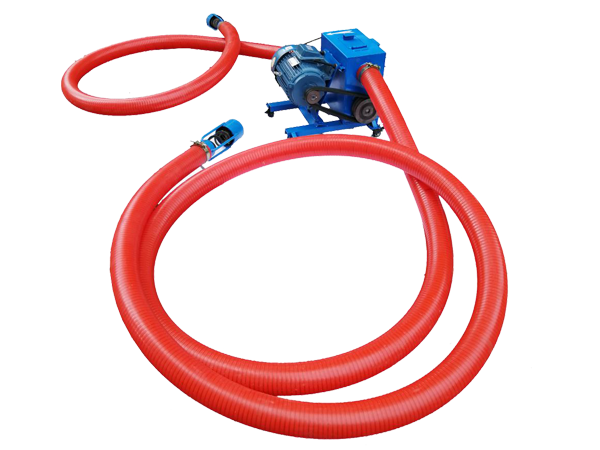

Concrete hose-type screw conveyor

Saturday December-27 2025 18:29:37

Concrete hose-type screw conveyor uses a flexible hose to transport concrete from one location to another in a closed system. The hose is made of wear-resistant rubber or reinforced polyurethane composite material, providing flexibility and impact resistance. The screw is made of high-strength alloy steel or surface-treated wear-resistant steel. Its conveying capacity ranges from 5-30 m³/h. The conveying distance is limited by the drive power and material characteristics; the horizontal conveying distance is 15-20 meters, and the inclined conveying distance will be correspondingly shorter.

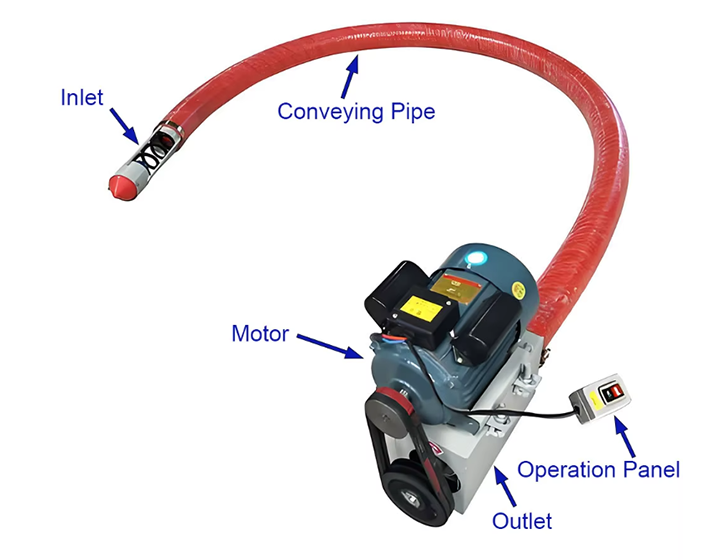

How does a concrete hose-type screw conveyor work?

A concrete hose-type screw conveyor uses a drive motor to rotate the screw shaft. The screw blades inside the flexible hose generate a continuous propulsive force, pushing the concrete axially to the discharge end. Due to the hose's elasticity and a certain degree of internal wall adhesion, a relatively stable force state is formed between the concrete and the pipe wall as it is pushed. Compared to ordinary tubular or trough-type screw conveyors, the difference lies in the flexibility and bendability of the hose. Traditional equipment relies on a rigid shell and can only be arranged in a straight line or at limited angles, while the hose structure can adapt to complex paths and, to a certain extent, buffer impacts and reduce wear.

Advantages of Concrete Hose-Type Screw Conveyors

The hose and flexible screw of a concrete hose-type screw conveyor have a certain gap, allowing for some mixing of concrete during transport, helping to maintain the homogeneity of the concrete and preventing the separation of slurry and aggregate. The equipment is a closed pipe, preventing dust and slurry splashing during concrete transport, reducing material waste. The equipment has better freedom of movement than rigid pipes, allowing for bending at multiple angles from 0 to 90 degrees.

Technical Parameters of Concrete Hose-Type Screw Conveyors

| Parameter Category | Parameter Range |

| Pipe Diameter (mm) | 40 / 50 / 65 / 75 / 90 / 110 / 130 |

| Conveying Capacity (m³/h) | 0.2 – 25 |

| Conveying Distance (m) |

Horizontal: 2 – 20 Vertical: 2 – 8 |

| Working Pressure (MPa) | ≤ 0.3 (Low pressure or micro-pressure) |

| Hose Material | Food-grade PU / Industrial-grade PU / Rubber composite tube |

| Hose Service Life | 1 – 5 years |

| Screw Material | Spring steel / Stainless steel (304/316) |

| Screw Rotating Speed (rpm) | 300 – 1400 |

| Driving Power (kW) | 0.75 – 11 |

| Conveying Angle | 0° – 90° |

| Applicable Materials | Powder, granules, small lumps |

| Working Temperature (℃) | -10 ~ +60 (Standard PU) |

Prices of Concrete Hose-Type Screw Conveyors

The price of a concrete hose-type screw conveyor varies depending on its conveying capacity, drive power, materials, and brand. A 150mm inner diameter, approximately 10-meter long device with a 7.5kW motor costs between $5,000 and $10,000. When purchasing, you can provide the supplier with your requirements regarding the conveying capacity and length of the equipment to obtain a suitable price.

Applications of Concrete Hose-Type Screw Conveyors

Concrete hose-type screw conveyors are used for plastic concrete, medium-flow fresh concrete, and mortar-type concrete containing fine aggregates. They are commonly used in precast component plants, prefabricated building production lines, tunnel lining construction, short-distance conveying in areas where small pumps cannot reach, and construction sites requiring obstacle avoidance or temporary setups.

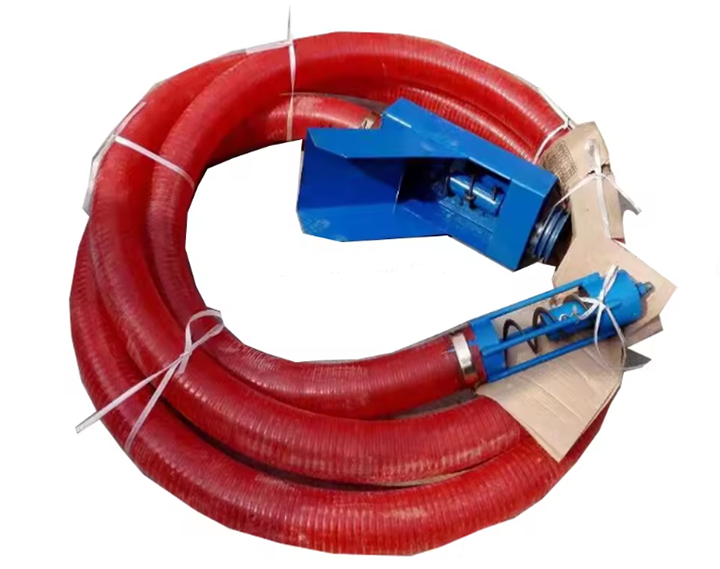

As a flexible and sealing device, the concrete hose-type screw conveyor should be used with a bending radius greater than the minimum specified value to avoid sharp bends that could cause blockages or excessive wear. The wear-resistant hose is a major consumable component. Its service life depends on the volume of concrete being conveyed, the abrasiveness of the aggregate, and the frequency of use. Under normal operating conditions, it can transport 5,000 to 15,000 cubic meters of concrete. This equipment is a short-distance, highly flexible, and cost-effective conveying system.