Concrete screw conveyors for fresh concrete

Monday March-07 2022 14:20:43

The cement screw conveyor is suitable for extracting, batching and conveying any type of cement, concrete, mud, fly ash, mineral powder and other powdery and granular materials, and is widely used in concrete mixing plants, stabilized soil mixing plants and other occasions. The cement screw conveyor can be conveyed horizontally or obliquely (conveying angle ≤45°). The feeding port adopts spherical feeding port, which can be rotated and easy to disassemble. It has good sealing performance, no water seepage and material leakage. It can be directly connected and fixed with its supporting equipment, no foundation is required, and it takes up little space.

Outstanding advantages of cement screw conveyor

1. The use of reducer heavy equipment has the characteristics of large torque and low noise.

2. The high-precision continuous seamless spiral blades of the cement screw conveyor after cold-working and hardening have an outer edge hardness of HB240, small pitch error and high dynamic balance accuracy.

3. There are various interface connection methods such as spherical hinge, nozzle, flange and square flange for the inlet and outlet.

4. There is an anti-seepage device at the connection of the shell pipe, which can avoid the cement agglomeration caused by the infiltration of rainwater outdoors, which will cause material blocking and boring events.

5. Each transmission part adopts floating connection, so that the spiral body, the hanging bearing and the tail form a suspended body, and no material is stuck or blocked.

6. The suspended intermediate hanging bearing frame increases the material transportation space and reduces the logistics resistance. Coupled with the design of small diameter, high speed and variable pitch, it ensures smooth, fast and even feeding.

7. It can realize the conveying, lifting and loading and unloading of materials, and at the same time carry out operations such as mixing, stirring, heating and cooling.

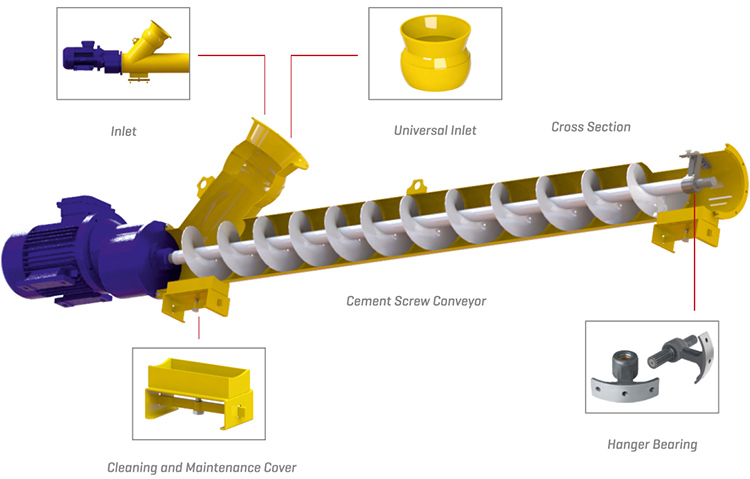

Detail and structure

The cement screw conveyor consists of a motor, a reduction box, an input section assembly, an intermediate section and an intermediate support body assembly, an output section assembly, a front support body assembly, and an oil injection lubrication system. The accessories are cables and connection canvas covers. , Hanging wire rope and accessories.

Motor: large torque, reliable and durable, matched with imported bearings, long service life.

Reducer: It adopts high-quality reducer, heavy-duty design, and has the characteristics of large torque and low noise.

Spiral blade: continuous spiral blade made of high-strength wear-resistant steel. After forming, the pitch error is less than 5mm and the blade surface is smooth, which ensures the uniformity and stability of material conveying, thus ensuring the repeatability of material measurement. The surface cold rolling treatment of cold work hardening is adopted during manufacture, and the hardness and wear resistance are about doubled compared with ordinary blades, and the outer edge hardness can reach HB240.

Connection method: Universal ball, cloth bag, flange and other connection methods, the user can choose freely.

Working principle:

The conveying principle of cement screw conveyor is basically the same as that of general screw conveyor: that is, like a rotating screw shaft, driving a nut to move along its axis, the screw body is equivalent to the screw shaft, and the material is equivalent to the screw conveyor nut. When rotating, the material is also continuously conveyed.

Industry application:

Cement screw conveyors are specially used for conveying or conveying cement and filler dust in concrete batching plants, cold filler dust in asphalt mixing plants, and cement and similar materials in building material processing plants.