Diatomaceous earth flexible screw conveyor

Wednesday January-28 2026 16:10:16

Diatomaceous earth flexible screw conveyor uses a spring rotating within a pipe to generate continuous thrust, overcoming the weight of the diatomaceous earth and enabling horizontal, inclined, and vertical lifting and conveying at various angles. The horizontal conveying distance is approximately 15 meters; the conveying capacity decreases slightly for inclined and vertical conveying. The conveying capacity is 0.5-15 m³/h, sufficient for conveying food-grade or industrial-grade diatomaceous earth.

Diatomaceous earth flexible screw conveyor components

The motor is a geared motor with variable frequency speed control and an IP55 or higher protection rating, providing dust and water resistance. The hose is made of PU material, which is wear-resistant, while the smooth inner wall of the pipe prevents diatomaceous earth powder from getting stuck and bacteria from growing. The helical spring is made of high-strength carbon steel or 304/316 stainless steel, resisting slight abrasion from the diatomaceous earth and allowing for quick removal for cleaning after use.

Advantages of Diatomaceous Earth Flexible Screw Conveyor

Diatomaceous earth powder has good flowability, allowing the flexible screw conveyor to transport it horizontally, inclined, vertically, or around obstacles without causing it to fall. The conveying pipe of the flexible screw conveyor is sealed, preventing external impurities from contaminating the diatomaceous earth, making it suitable for conveying food-grade diatomaceous earth where purity is critical. The flexible screw conveyor uses a low-shear force, smooth pushing method, unlike high-speed airflow or violent mechanical agitation, resulting in gentler material transport and less damage to the particle structure. The equipment lacks complex filters or cyclone separators; the main moving part is a single helical spring, making it easy to disassemble and clean, suitable for applications requiring cleaning.

Usage of Diatomaceous Earth Flexible Screw Conveyor

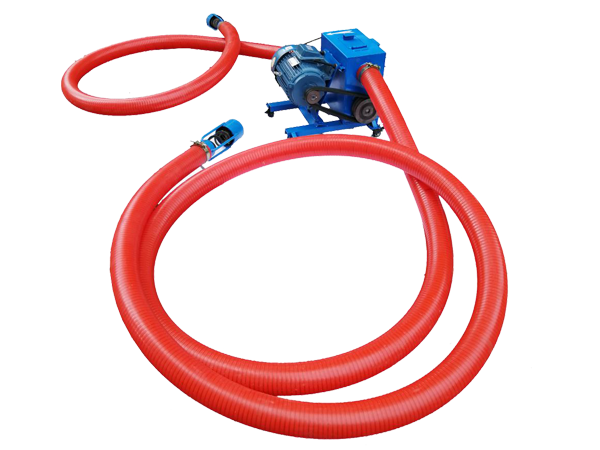

Diatomaceous earth flexible screw conveyors can be divided into two types based on conveying capacity: handheld and stationary motorized. Handheld types are lighter, while motorized types are heavier. A comparison of these two types follows.

Handheld conveyors are lightweight, allowing for easy handling by holding the handle. These use carbon brush motors, which have relatively low power but high speed, making them suitable for small-batch diatomaceous earth conveying or intermittent operations.

Fixed motor conveyors use belt drive, where the motor drives the screw via a pulley. This belt provides cushioning and protection; if foreign objects become lodged in the pipe, the belt slips, preventing the motor from burning out. This type offers better durability and is suitable for long-term, continuous diatomaceous earth conveying.

Diatomaceous earth flexible screw conveyor specifications

| Item | Parameter |

| Applicable Material | Diatomaceous earth |

| Conveying Capacity | 0.5 - 20 m³/h |

| Conveying Length | ≤ 15 m |

| Conveying Height | ≤ 8 m |

| Conveying Angle | 0–90° |

| Screw Diameter | Ø75 / Ø90 / Ø114 / Ø140 / Ø168 mm |

| Screw Type | Flexible spring steel screw |

| Conveying Pipe Material | Carbon steel / Stainless steel (304/316L) |

| Driving Method | Motor + Reducer |

| Motor Power | 0.75 – 7.5 kW |

| Sealing Type | Fully enclosed dust-proof |

Diatomaceous earth flexible screw conveyor case study

A brewery previously manually opened bags of diatomaceous earth and poured them into pre-coating tanks. This method resulted in significant dust emissions, inaccurate feeding, and high labor intensity. After adopting a diatomaceous earth flexible screw conveyor, the system starts at the unloading station. Operators pour entire bags of diatomaceous earth into sealed hoppers, and the material is then transported directly to the filter pre-coating tank 30 meters away in a closed, dust-free environment via a flexible screw conveyor. The conveying speed is controlled by a frequency converter and linked to the filtration process, enabling precise and automatic quantitative addition. After implementation, the conveying capacity increases to 9 m³/h, improving production speed, reducing labor intensity, and minimizing material waste.

Diatomaceous earth can be used in wall coatings, deodorizing materials, filters, soil conditioners, and wastewater treatment. The Diatomaceous Earth Flexible Screw Conveyor provides convenient conveying for diatomaceous earth in various applications. Different pipe diameters can be selected, or the type of equipment can be customized according to the specific application scenario of the diatomaceous earth to match the conveying needs.