Dry Sand Transfer Pump

Monday May-26 2025 14:34:27

What is a dry sand transfer pump?

What is the difference between a dry sand pump and a wet sand pump?

The main difference between a dry sand pump and a wet sand pump lies in the transfer medium and material state:

Dry sand pump: Mainly used to convey dry, granular materials (such as dry sand) with no or very little water content. It uses gas (such as air or nitrogen) as the transfer medium and conveys by pneumatic principle. It is suitable for materials that need to avoid moisture, or for occasions where dry powders and particles need to be conveyed over long distances, with high efficiency and low pollution.

Wet sand pump: Mainly used to convey a mixture of solid particles containing a large amount of liquid (usually water), that is, slurry (such as mud, wet sand, ore slurry, coal slime, etc.). It uses liquid as the main medium and generates centrifugal force through the rotation of the impeller to push the slurry out. It is suitable for handling fluids with high viscosity and containing solid particles, such as mining, dredging, sewage treatment, ash treatment in the power industry, etc. Wet sand pumps are usually designed to be wear-resistant and corrosion-resistant.

|

Features |

Dry sand pump |

Wet sand pump |

|

Conveying material state |

Dry granular materials (such as dry sand, fly ash, etc.), usually without water or with very low water content |

Solid-liquid mixture (such as mud, wet sand, etc.), solid particles suspended in liquid. |

|

Main transfer medium |

Gas |

Liquid (usually water) |

|

Conveying mode |

Can be dense phase transfer (high concentration, low speed) or dilute phase transfer (low concentration, high speed). |

Usually forced transfer, slurry flows in the pipeline. |

|

Applicable materials |

Dry sand (water content <5%, particle size ≤5mm) |

Wet sand (water content 10%-30%, containing clay/impurities) |

|

Typical application scenarios |

Construction concrete mixing station, casting molding machine sand supply, glass factory quartz sand delivery |

River dredging slurry delivery, mining tailings treatment, sewage treatment plant sludge delivery |

Advantages of dry sand pump

Dry sand faces many challenges in the transportation process, such as environmental pollution and health hazards caused by flying dust, blockage caused by moisture and agglomeration of materials, and severe wear of traditional mechanical equipment by dry materials. Traditional methods such as belt transfer or manual handling are not only inefficient, but also difficult to overcome the above problems. The dry sand transfer pump effectively solves these problems through its unique pneumatic transfer principle: it uses closed pipeline transportation to fundamentally eliminate dust leakage, significantly improves the working environment, and protects the health of workers.

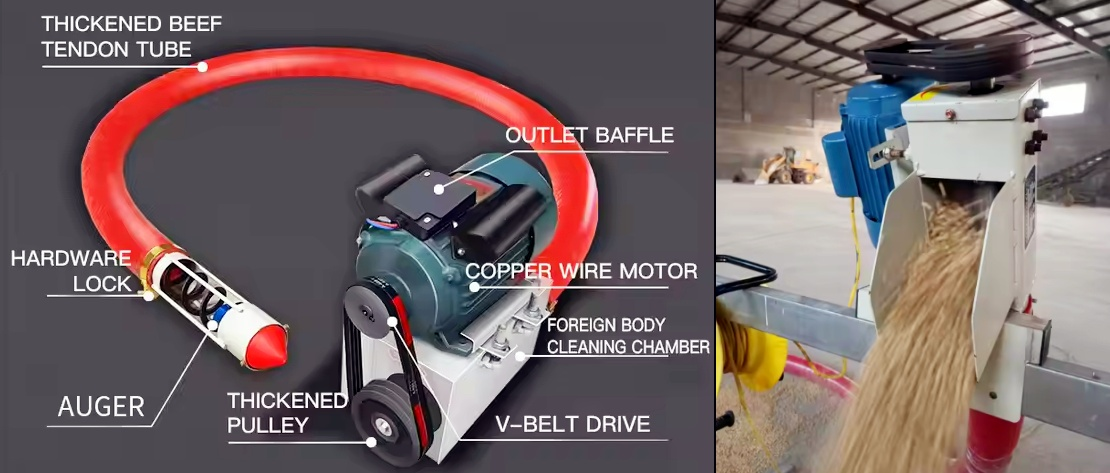

In addition, the dry sand transfer pump can accurately control the air flow speed and pressure in the pipeline. Even in the face of fine dry sand particles, it can maintain a stable and continuous fluidization state to avoid material accumulation or agglomeration in the pipeline, thereby greatly reducing the risk of blockage. In view of the abrasiveness of dry sand, modern dry sand transfer pumps usually use wear-resistant pipeline materials and special lining designs, and by optimizing the transfer speed and elbow design, reduce the impact and friction between the material and the pipeline wall, effectively extend the service life of the equipment and reduce maintenance costs.

What is the purpose of the dry sand transfer pump?

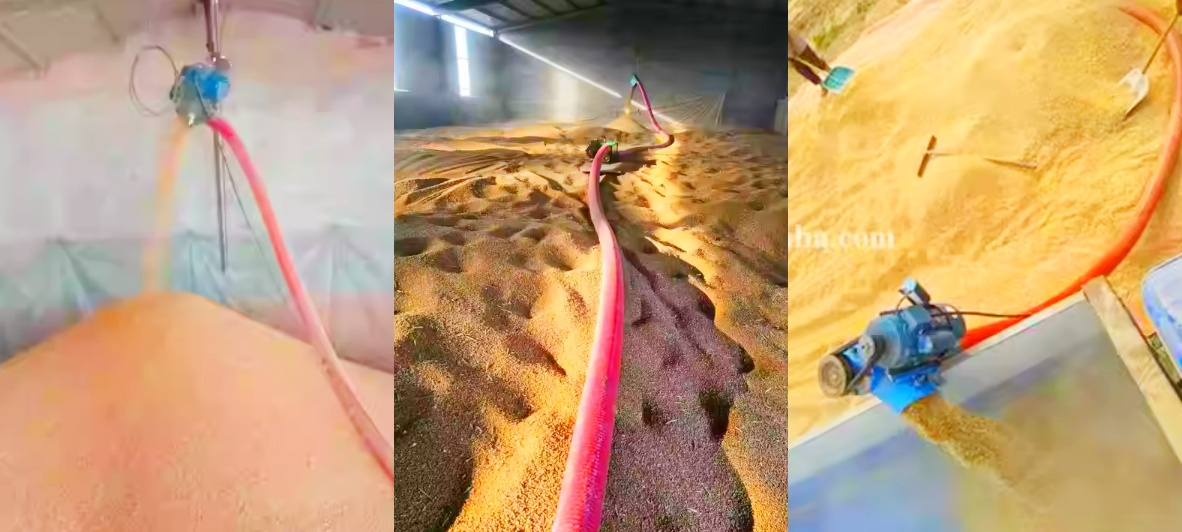

The dry sand transfer pump is mainly used to achieve efficient transportation of dry sand materials in closed pipelines, and is widely used in building materials, casting, chemical industry, power and other industries. In the dry-mix mortar production line, it can be used to transport dry sand from the storage bin to the mixing system to achieve automatic feeding; in the foundry workshop, the dried molding sand can be transported to the molding station to improve the sand loading efficiency and avoid dust pollution; in quartz sand deep processing enterprises, the dry sand transfer pump can undertake the task of transferring materials from the drying section to the grading and packaging section, reduce manual intervention, and improve cleanliness; in addition, in cement plants, glass plants and other powder transfer places, this equipment is also often used to accurately deliver dry sand to the feeding port or reactor to meet the requirements of closed and efficient transfer. This pump is particularly suitable for working environments with high requirements for transfer accuracy, continuity and environmental protection.

Dry Sand Conveying Pump Supplier

Xinxiang Dahan Machinery is an enterprise focusing on the research and development and manufacturing of powder and granular material transfer and screening equipment, providing screening and transfer equipment of various models and specifications. The company mainly produces material handling equipment such as vibrating screens, screw conveyors, bucket elevators, vacuum loaders, and some products cover dry sand transfer systems.

When choosing Dahan Machinery's dry sand transfer pump products, it is recommended to customize according to the following factors:

Conveying material type and particle size

Conveying distance and height

Feeding frequency and batch transfer volume

Whether dust removal, sealing or wear-resistant design is required

Plant space and layout restrictions

If you need to know more about the specific parameters (such as air supply pressure, transfer volume, whole machine power, etc.) or quotation of a certain model of Dahan Machinery's dry sand transfer pump, you can provide specific transfer requirements, and we can help you organize detailed technical parameter tables or compare similar equipment.