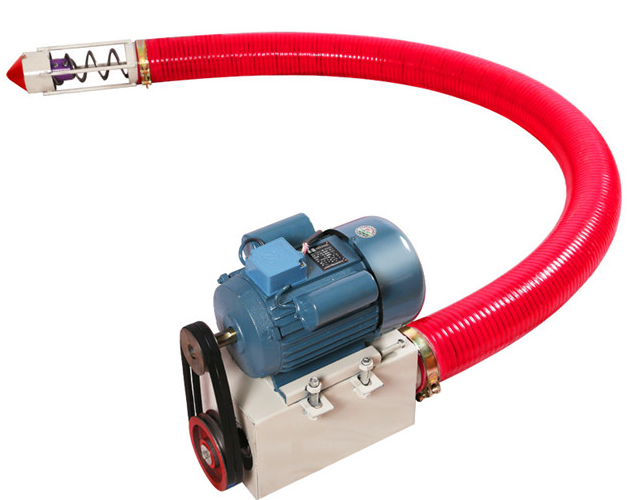

Feed hose screw conveyor

Friday December-12 2025 13:43:09

Feed hose screw conveyor is a continuous feeding conveying device that combines the principles of rigid screw conveying with the characteristics of flexible hose wrapping. It typically consists of a drive motor, a flexible screw, a wear-resistant hose, and inlet/outlet ports.

Feed hose screw conveyors are available with screw diameters of Φ65mm, Φ108, Φ133, and Φ300mm, which can be selected according to the particle size and conveying volume of the material. Different models have different conveying capacities, generally ranging from 0.5 to 10 tons per hour. Hose materials include PVC, PU, rubber, food-grade materials, and stainless steel wire reinforced hoses. The machine is highly flexible; it can be handheld, mounted on a stand, or hung on a truck, enabling horizontal, vertical, or curved conveying.

What are the advantages of a feed hose screw conveyor?

The hose of a hose screw conveyor can be bent, coiled, and even bypass obstacles, allowing for flexible arrangement in narrow or complex spaces, improving site adaptability. The fully enclosed conveying pipe ensures a sealed environment during transport, preventing dust leakage and cross-contamination. Structurally, it eliminates the complex components of traditional conveyors, such as bearings and hanging parts, resulting in fewer maintenance points and simplified cleaning and maintenance. The flexible screw has low rotational friction resistance, leading to low energy consumption, low noise, and smooth conveying. It offers versatile installation options, allowing for both fixed and rapid relocation, supporting horizontal, inclined, and even vertical conveying. Material conveying speed can be flexibly controlled by changing the screw speed.

Feed Hose Screw Conveyor Types

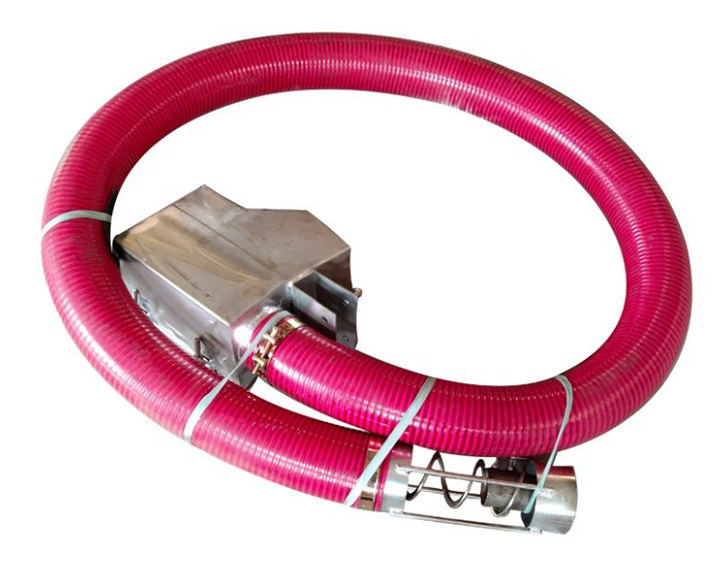

Feed hose screw conveyors can be categorized into three types based on their application: mobile, fixed, and inclined. The appropriate type can be selected based on the specific working conditions of the conveyed material.

Mobile conveyors are typically equipped with casters with brakes and lightweight supports. The motors often use universal voltage designs for easy connection to on-site power supplies. They are suitable for scenarios where material conveying points are not fixed, frequent changes of workstations are required, or temporary refueling is needed, such as small production lines, laboratories, multi-variety batch production, farm feed feeding, or construction site material distribution. They can be used with small mixers, packaging machines, or directly for unloading trucks/containers into temporary storage warehouses.

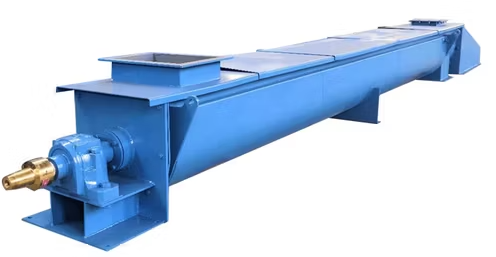

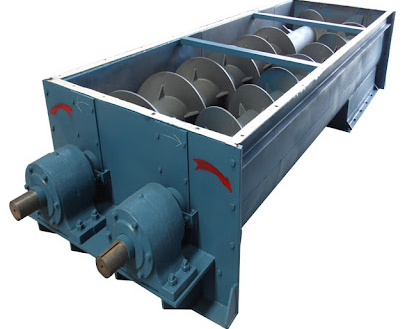

Fixed-type conveyors are permanently installed in specific locations via flanges or brackets, ensuring stable and reliable operation and facilitating interlocking control and centralized management. They are typically made of carbon steel or stainless steel. Suitable for continuous or batch conveying in fixed process flows, such as stable raw material supply from storage tanks to production equipment. Conveying capacity ranges from 0.5-100 m³/h or higher, and hose length can be customized according to the process layout, with a maximum length exceeding 20 meters.

Tipping-type conveyors can convey materials at inclines or verticals, offering flexible installation position and orientation adjustments. Suitable for complex layouts with limited space, where the conveying path must bypass obstacles, or where there are height differences or angle changes between inlet and outlet. The hose bending radius is a critical parameter, typically not less than 6-8 times the hose diameter. Conveying capacity is affected by the bending angle; vertical conveying will result in lower capacity.

How to choose the diameter of a feed hose screw conveyor?

When selecting the diameter of a feed hose screw conveyor, it can be matched according to the material type and particle size. For powdery materials, such as flour and premixed powders, the particle size is typically less than 0.5mm, and a pipe diameter of Φ40–60mm can be selected to ensure smooth conveying and prevent clogging. For feed pellets and plastic pellets, the particle size is between 0.5–5mm, and a pipe diameter of Φ60–90mm can be selected. For large particles or high-flow-rate materials, such as corn, soybeans, and sawdust pellets, the particle size is typically 5–15mm, and a pipe diameter of Φ90–120mm can be selected to reduce pipe wear and the risk of clogging.

Feed Hose Screw Conveyor Prices

PVC standard hoses cost approximately $3 - $8/meter and are suitable for conveying general powders and granules, but their wear resistance and weather resistance are average. PU hoses cost approximately $10 - $25/meter and have good wear resistance, oil resistance, and aging resistance, making them a common choice in the feed and plastic pellet industries. Food-grade hoses cost approximately $30 - $60/meter and are made of materials that meet FDA/EC standards to ensure food safety. Reinforced steel wire hoses cost $50 - $120+/meter. Embedded steel wire spiral, pressure-resistant, vacuum-resistant, wear-resistant, and long-lasting, it is used for conveying highly abrasive chemicals, mineral powders, and heavy materials. Besides the hose material, the spiral material, conveyor diameter, length, motor power, and customization level also affect the price of a feed hose screw conveyor, generally ranging from $1800 to $6500.

Feed Hose Screw Conveyor Suppliers

Feed hose screw conveyor suppliers each have their own strengths. Some excel in material manufacturing, some in production line construction, and some in precision engineering. Suppliers are located in the United States, Germany, China, India, and other regions. Dahan Machinery provides both standard machines and flexible customized designs based on customer material characteristics, conveying capacity, and layout, with short delivery cycles and global export capabilities.

Feed hose screw conveyors are suitable for conveying various bulk materials, from fine powders to small particles and fragments. They are available in various models and can be flexibly configured according to material particle size, conveying capacity, distance, and industry requirements. The price and lifespan of equipment are determined by the different materials of hoses and spirals. Reasonable selection of pipe diameter, material, power and layout can provide factories with stable and low-maintenance conveying solutions.