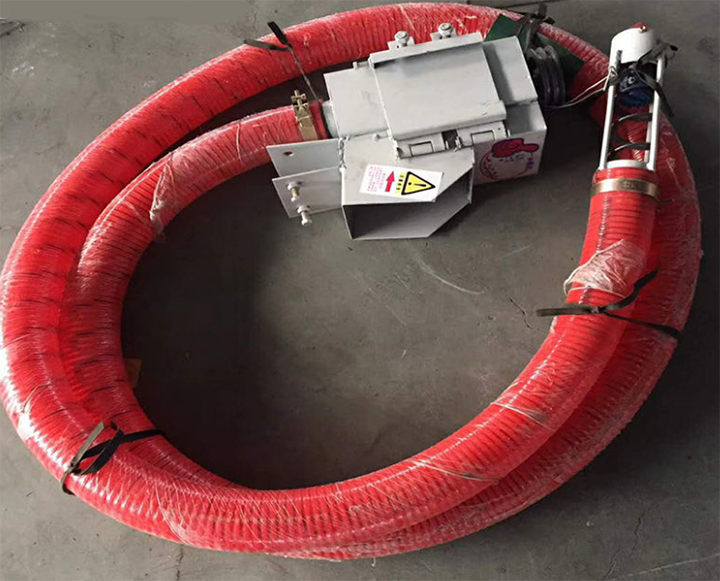

Feed powder Hose type screw conveyor

Thursday January-08 2026 08:32:28

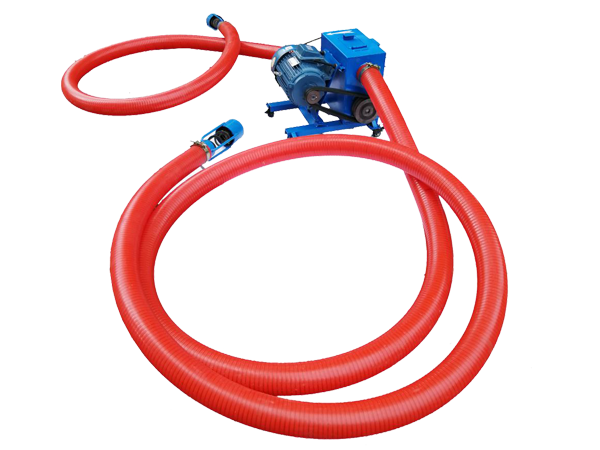

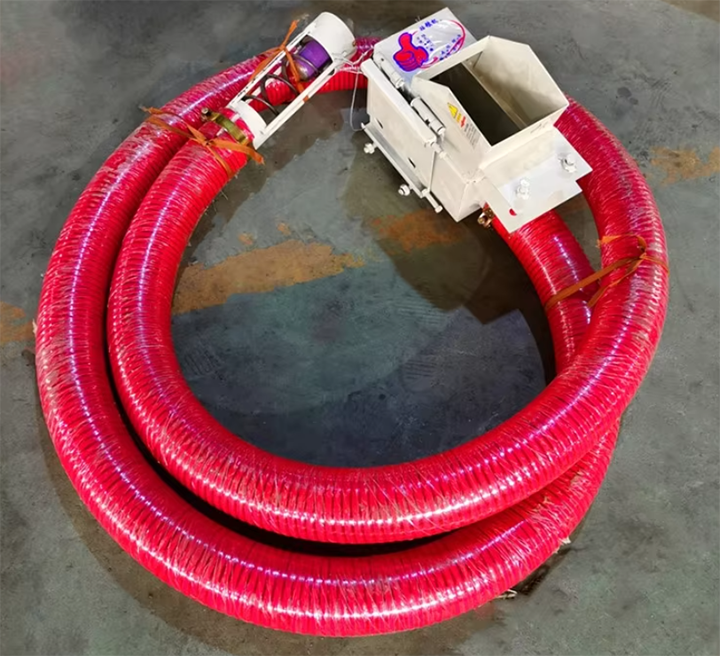

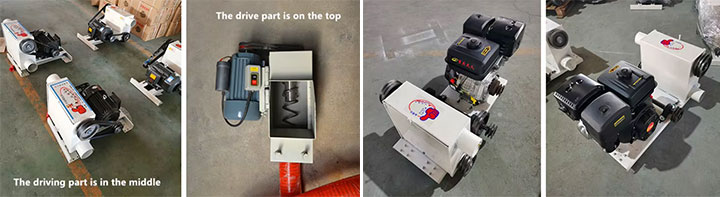

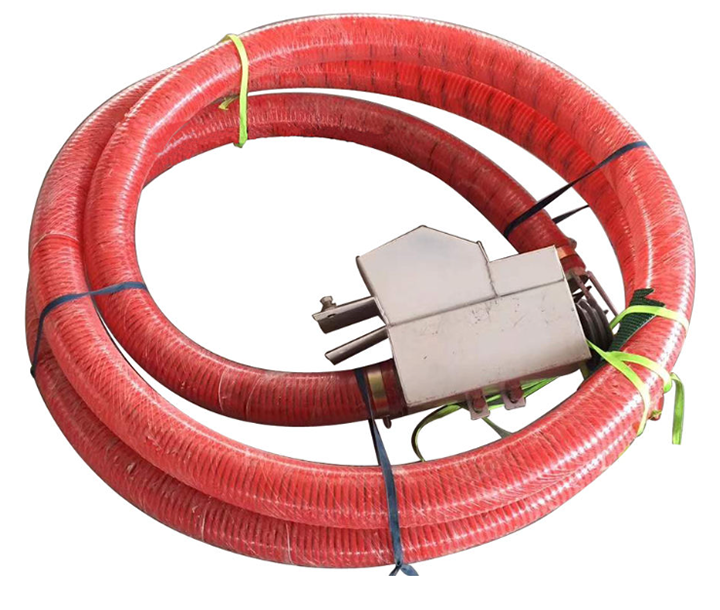

Feed powder Hose type screw conveyor enables the closed-loop transport of feed powder from storage silos to mixers, from feeding points to packaging machines, and other stages. The equipment uses a flexible hose as the conveying channel, with an internal helical spring or wire spiral propelling the material forward. The hose diameter ranges from 50mm to 150mm, and the conveying capacity, depending on the model, is typically between 1 and 10 cubic meters per hour. Conveying lengths range from 5 meters to 15 meters. Models include FHS-50, FHS-80, and FHS-100, where the numbers represent the hose diameter in millimeters. The machine is priced at approximately $1,200 to $4,500.

How does the Feed Powder Hose Type Screw Conveyor work?

When the motor starts, it drives the spiral inside the Feed Powder Hose Type Screw Conveyor to rotate. The spiral is typically made of wear-resistant spring steel or a special plastic, and its helical blades form a closed propulsion space with the inner wall of the hose. Feed powder enters through the inlet and falls into these spiral spaces. As the auger rotates continuously, the powder is propelled forward by the blades. Because the hose itself is flexible, the material can adapt to changes in the conveying path. It can also be equipped with an adjustable-speed motor to adjust the conveying speed according to the flowability and density of the feed powder.

Advantages of Feed Powder Hose Type Screw Conveyors

Feed powder hose type screw conveyors offer advantages such as flexible conveying direction, wear resistance, and easy assembly. The following compares its advantages with rigid screw conveyors.

Compared to traditional rigid screw conveyors, feed powder hose-type screw conveyors can be arranged horizontally, inclined, or even vertically, easily bypassing obstacles and adapting to complex plant structures. Rigid screw conveyors, on the other hand, must be straight lines or zigzag lines with limited angles, requiring more space and more complex support structures for installation.

Hose-type screw conveyors typically have quick-connect couplings or flanges at both ends, making disassembly and assembly convenient. They facilitate cleaning, inspection, and replacement of worn parts, making them suitable for feed production lines requiring frequent material changes or rigorous cleaning. Rigid conveyors, on the other hand, are difficult to clean and have many dead corners.

Applications of Feed Powder Hose Type Screw Conveyors

Feed powder hose type screw conveyors have a wide range of applications. In the raw material receiving stage, they can transport powdered raw materials such as soybean meal, fish meal, and premixes from the discharge pit to the main feed silo. In the batching process, they can transport various trace additives and main raw materials from the batching scale to the mixer, automating the formulation process. Before and after the pelleting or extrusion process, they can be used to transport pulverized powder to the conditioner or to recover broken pellets. Before packaging finished feed, they can be used to transport powdered feed from the finished product silo to the buffer hopper of the packaging machine.

Feed Powder Hose Type Screw Conveyor Parameter Table

| Product Name | Flexible Screw Conveyor | ||

| Working voltage | 220V/380V | ||

| Maximum power | 5.5kw (single-phase 6-inch available) | ||

| Conveying distance | 3-15m | ||

| Applicable scope | Wheat/corn/rice/millet/soybeans/mung beans/granular materials and cement flour dry powder, etc | ||

| Size corresponds to outer diameter |

3.5 inches 100mm |

4 inches 120mm |

6 inches 160mm |

| Pipe wall thickness | 5mm | 5mm | 6.5mm |

| Harvest every hour | 6-7 tons | 8-10 tons | 18-20 tons |

| Supporting Jiaolong | 75 spring | 85 spring | 122 spring |

| Pipe material | Cow tendon hose | Cow tendon hose | Cow tendon hose |

| (Applicable temperature | -30℃—+38℃ | ||

| Use height | 220v (0-4 meters)/380v (0-5 meters) | ||

| Bending radius | 1.5m | 2m | 2.5m |

Feed Powder Hose Type Screw Conveyor Price

The price of a feed powder hose type screw conveyor varies depending on the specific configuration of the equipment. For a mid-range model with a standard motor, 10 meters in length, and 100mm pipe diameter, the price is approximately between $2,800 and $3,500. Prices increase progressively for different hose materials, such as ordinary polyurethane, abrasion-resistant rubber, or food-grade Teflon coating. Each additional meter of length or pipe diameter adds approximately $150-$300 to the price. The price also varies depending on whether the equipment uses a standard motor, an explosion-proof motor, or a variable frequency drive motor.

Feed Powder Hose Type Screw Conveyor Case Study

At a 50,000-ton-per-year aquatic feed plant, the premix addition process faced challenges due to limited space and high dust levels. The plant introduced two FHS-80 Feed Powder Hose Type Screw Conveyors, 8 meters and 12 meters in length respectively. The equipment successfully transported trace premixes such as vitamins and minerals from the second-floor micro-volume silo, through complex pipe shafts and beams, to the mixer on the first floor, bypassing the existing production line structure. The conveying capacity remained stable at 2.5 cubic meters per hour, meeting the production cycle. After one year of operation, the dust concentration in this area of the workshop decreased by 90%, and material loss was also reduced.

The feed powder hoose type screw conveyor can be used in various feed mills, livestock farms' self-mixing workshops, and grain processing applications. Dahan Machinery, the manufacturer, typically possesses customization capabilities, providing tailored solutions from pipe diameter, length, material, drive to control system based on the specific space dimensions of the customer's workshop, the characteristics of the feed powder, production capacity requirements, hygiene standards, and automation integration needs. This allows the equipment to be integrated into different production lines for conveying feed powder.