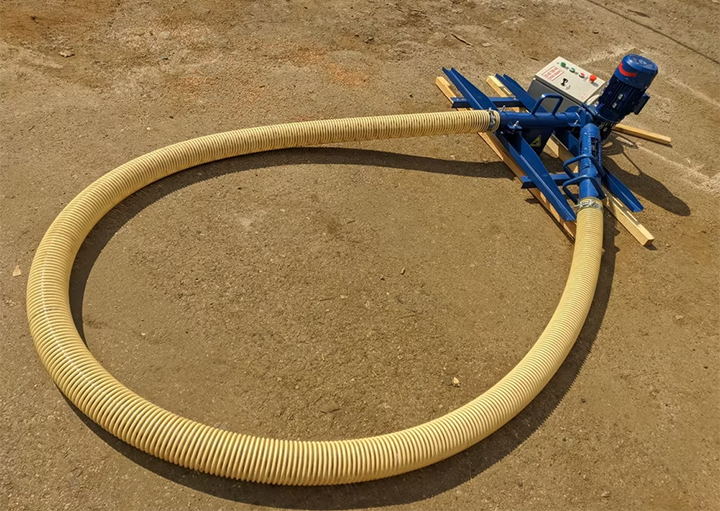

Flexible Grain Auger

Friday September-19 2025 12:07:54

What is a Flexible Grain Auger?

Flexible Grain Auger are commonly used in agriculture and industry to transport materials such as seeds and feed. Their function is to rapidly transfer grains such as wheat, corn, and rice through a flexible hose and power system, addressing the low efficiency and labor intensity of traditional manual handling.

Different Flexible Grain Auger models have varying conveying capacities. Conventional models can transport 2-20 tons of grain per hour. The conveying length is flexible and adjustable, ranging from 3-5 meters to over 20 meters. The conveying height can reach up to 10 meters, allowing grain to be transported directly to silos, trucks, or storage tanks. Hoses are often made of wear-resistant rubber or high-strength PVC, resisting aging and tearing. Core transmission components are made of galvanized steel or stainless steel, ensuring long-term stability and durability.

Flexible Grain Auger Advantages

Compared to traditional grain conveying equipment, the Flexible Grain Auger offers several advantages: Portability: The unit is lightweight, with small models weighing only 20-30 kg, making it easy for one person to carry. Its foldable hose makes it compact and easy to transport when folded. Safety: Its enclosed conveying structure prevents grain spillage and dust dispersion, and protective covers on key operating components reduce safety risks. Cleaning and maintenance: The hose's smooth interior leaves minimal grain residue, making it easy to clean. Its simple structure and minimal wearing parts mean routine maintenance only requires checking the power system and hose seals, resulting in low maintenance costs. Flexible: The hose's angle and length can be adjusted, allowing for horizontal, inclined, or vertical conveying, meeting the needs of diverse operating scenarios such as breweries, distilleries, and grain silos.

Flexible Grain Auger Technical Specifications

| Model No. |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS120 | 4 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS-160 | 4meter | 160mm | 10—15 | Three phase-5KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5meter | |||||||

| 6meter | |||||||

| 8meter | |||||||

| (Customized) | |||||||

Flexible Grain Auger Application Scenarios

The Flexible Grain Auger is widely used in agriculture, livestock farms, and other fields. In agricultural production, it helps farmers transfer harvested grain, such as transferring it from a harvester hopper to a farm tricycle or from the ground to a silo. In grain storage, it helps grain depots transfer grain between silos and transport bulk grain to packaging equipment. In grain processing, it helps flour mills and feed mills transfer raw materials from storage silos to processing equipment, reducing labor. It can also be used to transport feed pellets at small farms, assist in loading and unloading small grain containers at ports and terminals, and clear out backlogs such as leftover grain from the corners of silos. For outdoor use or in areas with limited power, a manual grain vacuum can be used as a backup.

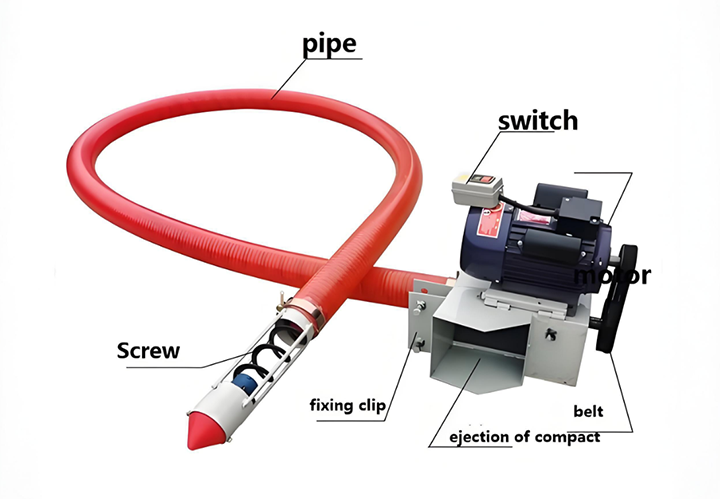

Flexible Grain Auger Structure

Structurally, the Flexible Grain Auger primarily consists of a power system, conveying hoses, transmission components, and control devices. It comes in three power sources: Electric-driven models offer low noise and energy consumption, making them suitable for fixed locations with stable power supplies, such as grain depots and processing plants; hydraulic-driven models offer high torque and strong overload capacity, often used with tractors and other agricultural machinery for mobile field operations; gasoline or diesel-powered models offer independent power and high mobility, making them suitable for remote farmlands without power. Additionally, there are hand-cranked grain hoppers, which, while offering a smaller capacity, are low-cost and energy-free, making them suitable for transferring small batches of grain over short distances.

Choosing a Flexible Grain Auger

Selecting a flexible grain augmenter depends on your specific needs. Small-scale farmers can choose models with a capacity of less than 5 tons per hour and a length of 5-10 meters. Large-scale operations in grain depots require models with a capacity of 20 tons or more and a length of 15 meters or more. Choose the drive type based on the operating environment. Electric drives are preferred for sites with stable power supply, while gasoline or diesel engines are preferred for fields without power. Hydraulic drives are also recommended for use with tractors. Manual grain hoppers are suitable for users with limited budgets or those who need to transport small quantities.

Flexible grain augments have become an important auxiliary equipment in grain storage, livestock feed, and processing. Carbon steel is cost-effective and wear-resistant, making it suitable for drying grain. Stainless steel is corrosion-resistant and suitable for handling wet or corrosive grain, but it is more expensive. Materials such as nylon and polyethylene are lightweight, offer low friction, and can reduce breakage of delicate grain. Due to its material and practicality, the flexible grain augment has become a reliable choice for material conveying in the grain industry.