Flexible Screw Conveyor For Chemical Powder

Wednesday December-10 2025 15:04:28

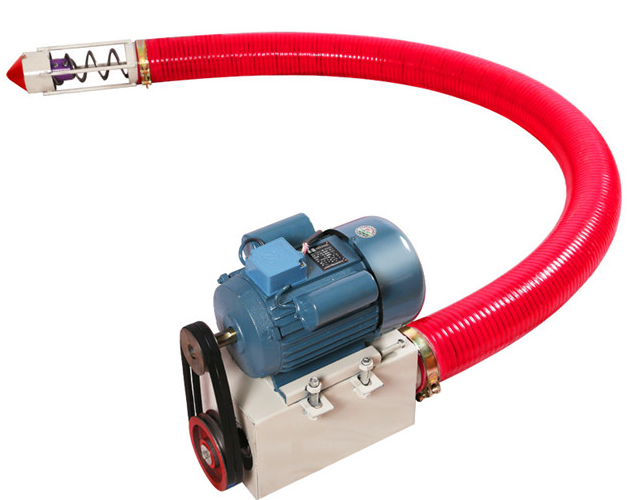

Flexible Screw Conveyor For Chemical Powder is a flexible conveying device for transporting chemical powders that are prone to floating, corrosiveness, hygroscopicity, and agglomeration. Its conveying capacity typically varies from 1 to 40 m³/h depending on the screw diameter, rotational speed, and the characteristics of the chemical powder. Common pipe diameters include φ60, φ75, φ90, and φ120 mm, and can be customized according to the bulk density and flowability of the chemical powder.

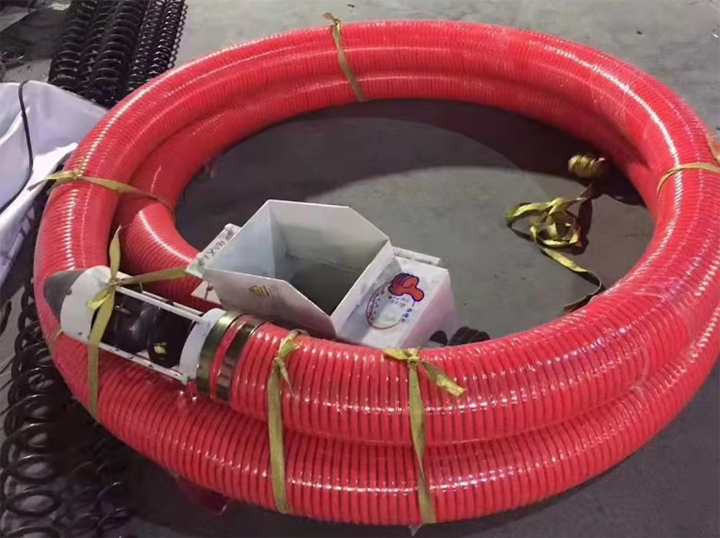

Flexible Screw Conveyor for Chemical Powder is available in materials such as 304/316 stainless steel, food-grade or anti-static PE/PU hoses, and carbon steel bases. Conveying distances are typically 3 to 20 meters. Installation can be horizontal, inclined, or vertical, and it is compatible with interfaces on various equipment such as silos, mixers, packaging machines, and reactors.

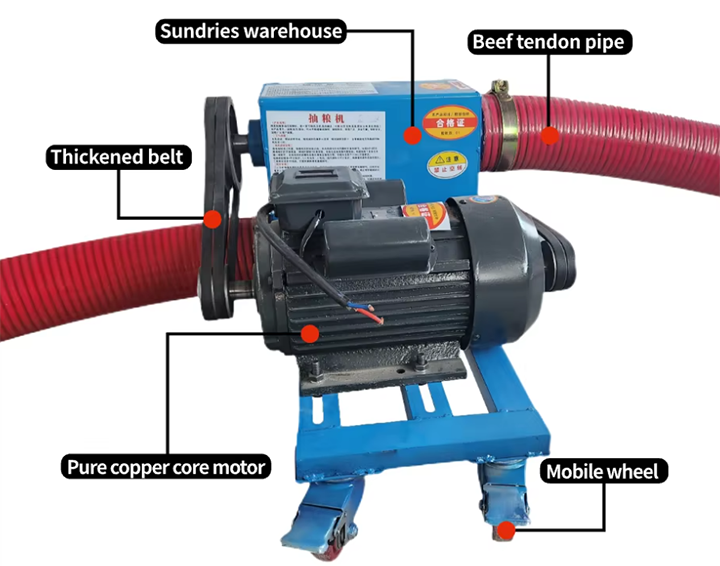

Flexible Screw Conveyor for Chemical Powder Components

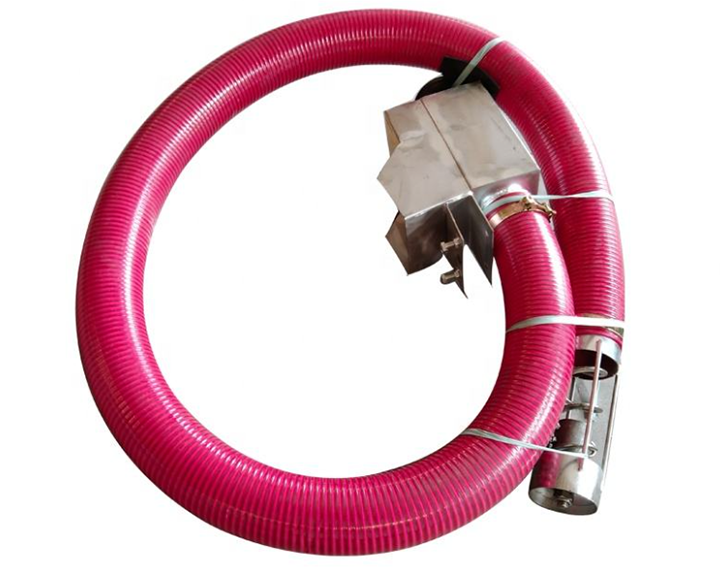

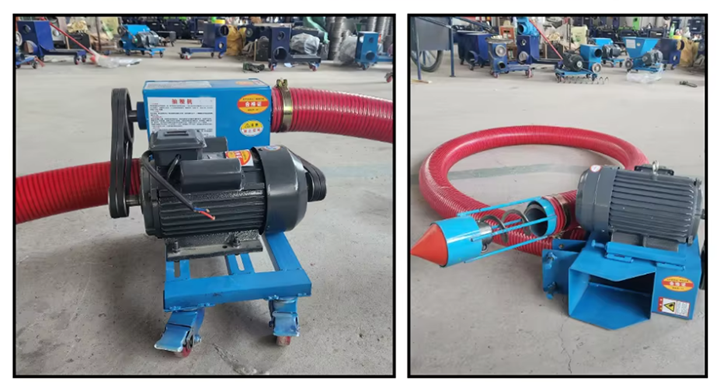

The flexible helical spring in the Flexible Screw Conveyor for Chemical Powder is made of high-strength, wear-resistant steel and is responsible for continuously conveying the chemical powder forward. The conveying pipe is typically UPE or food-grade flexible tubing, providing a sealed channel to prevent chemical powder leakage. The drive unit includes a motor, reducer, and mounting base, providing power to the system. The feed inlet is designed in various forms, such as funnels and flange interfaces, to adapt to different feeding equipment. The discharge outlet can be customized in direction and shape according to process requirements.

Flexible Screw Conveyor for Chemical Powder Characteristics

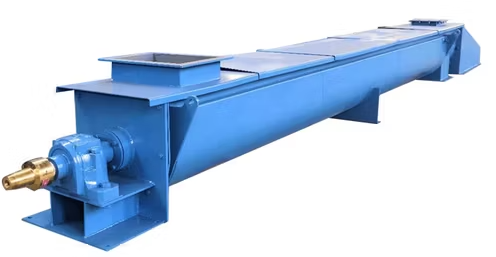

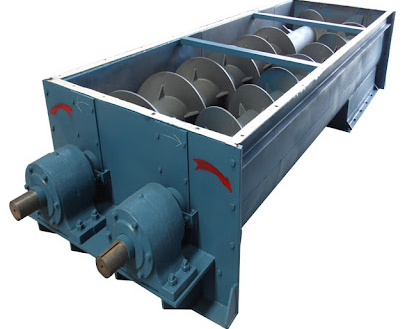

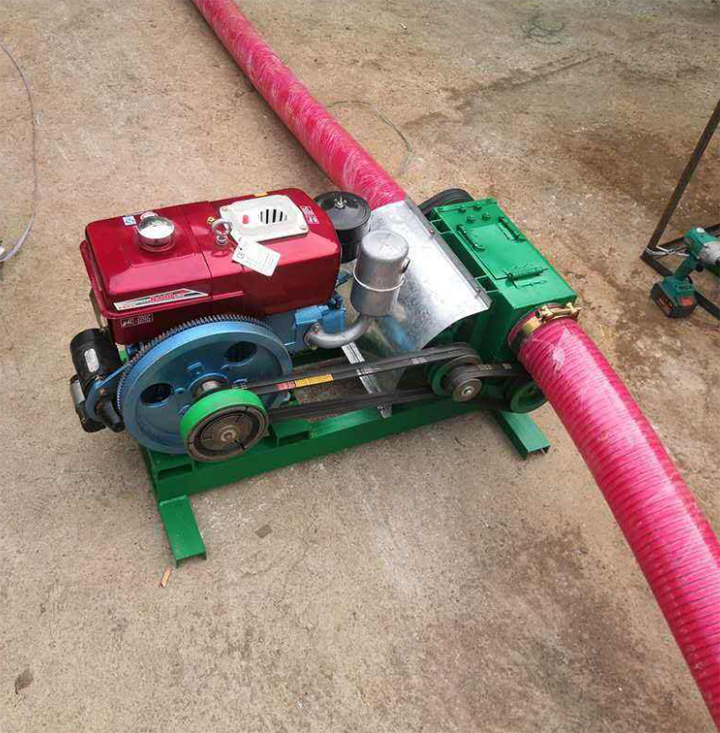

The enclosed conveying structure of the Flexible Screw Conveyor for Chemical Powder prevents dust leakage, avoiding environmental pollution during chemical powder transport and reducing operator exposure risks. The flexible screw creates a stable and gentle material flow during operation, minimizing powder breakage or property changes, making it suitable for conveying various chemical powders that are lightweight, easily floatable, hygroscopic, or prone to agglomeration. The advantage of flexible screw conveyors over rigid screw conveyors is that the pipe can be bent arbitrarily, bypassing obstacles for conveying, and can perform horizontal, inclined, and vertical conveying. This allows for multi-purpose operation. Flexible screw conveyors can also be handheld, stand-up, or fixed to a truck or a specific location to meet the actual needs of chemical powder processing.

Flexible Screw Conveyor for Chemical Powder Price

The price of a flexible screw conveyor for chemical powder is affected by factors such as pipe diameter, length, and material. Typically, a standard model with a 65mm diameter, 5-meter length, 304 stainless steel construction, and a basic motor costs approximately $800 - $2500 USD. A machine with a 90mm diameter and 5–10m length costs approximately $1000 - $3500 USD. A high-end industrial model with a 150mm diameter, 15-meter length, 316L stainless steel or a special coating, equipped with a variable frequency drive and an explosion-proof motor, can range from $8000 to $15000 USD.

Flexible Screw Conveyor for Chemical Powder Suppliers

Manufacturers worldwide, including those in the US, Italy, the UK, and China, specialize in manufacturing flexible screw conveyors for chemical powders. The US, Italy, and the UK provide high-precision machinery, while Chinese manufacturers offer economical and customized products. For example, Dahan Machinery provides a complete customization service for flexible screw conveyors, including motors, piping materials, and inlet/outlet ports, offering personalized solutions for equipment and components.

Applications of Flexible Screw Conveyor for Chemical Powders in Chemical Powders

Flexible screw conveyors for chemical powders transport various chemical powders such as pigments, dyes, resin granules, calcium carbonate, talc, pesticide powders, food additives, and plastic masterbatches. Their airtight design prevents toxic, irritating, or hygroscopic materials from escaping into the air.

The Flexible Screw Conveyor for Chemical Powder is a machine for conveying chemical powders. The screw material and shape can be customized according to production conditions, such as custom stainless steel, acid and alkali resistant materials, and thickened screws. The conveying pipe material can be manufactured as anti-static, food-grade, high-temperature resistant, or thick-walled. Inlet and outlet interface sizes can be designed with different types such as quick couplings, flanges, and material level interlocks. Machines can be designed to effectively convey chemical powders with varying properties.