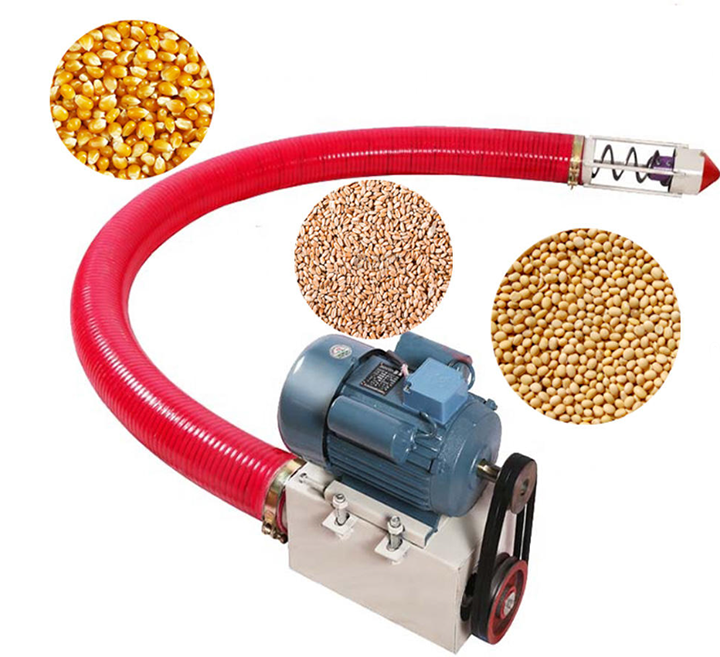

Flexible Screw Conveyor For Grains

Tuesday December-02 2025 16:07:59

Flexible Screw Conveyor For Grains consists of a flexible spiral steel wire and an surrounding flexible conveying tube, used for conveying granular, powdery, slightly viscous, or highly free-flowing grains and cereals.

The flexible screw conveyor for grains is available in hose diameters ranging from 40 mm to 200 mm. A single unit can convey horizontal distances from 3 to 20 meters and vertical heights from 10 to 15 meters. The equipment can accommodate any inclination angle, from horizontal to vertical. Conveying capacity is typically 2 to 20 tons per hour, depending on the hose diameter, screw speed, and material characteristics. Hose materials include wear-resistant polyurethane, food-grade polyethylene, and high-strength steel-tube spring composite hoses.

How does the Flexible Screw Conveyor convey grains?

When the Flexible Screw Conveyor for Grains is powered on, the motor drives the screw to rotate. The grains at the inlet are propelled forward along the tube by the rotating screw until they are discharged from the outlet. The motor speed can be set. Flexible Screw Conveyors for Grains are flexible enough to bend and adapt to complex spatial layouts, short-distance transport, and winding routes for grains. The pipe diameter is typically selected based on the conveying capacity and grain type. The discharge port can directly deliver the grain to processing equipment or a silo.

Advantages of Flexible Screw Conveyor for Grains

Flexible Screw Conveyor for Grains feature flexible pipes that can bend around obstacles, easily adapting to complex and narrow factory layouts—something rigid conveying equipment cannot match. The enclosed piping reduces dust emissions, ensuring a clean working environment and minimizing material loss and cross-contamination risks. Most models are designed with quick-release couplings, allowing the screw to be pulled out entirely from the pipe for easy cleaning, inspection, and maintenance. A single unit can handle horizontal, inclined, and vertical conveying, saving space and cost associated with switching between multiple units. The simple structure and lower initial investment and installation costs compared to pneumatic conveyors or traditional trough screw conveyors also result in relatively lower energy consumption.

Types of Flexible Screw Conveyor for Grains

Flexible screw conveyor for grains can be categorized into horizontal, inclined, and vertical conveying based on the direction of grain transport. These different conveying methods avoid frequent changes in equipment types while still providing flexible grain transport capabilities.

Horizontal Conveying Type: Used for horizontal or slightly inclined conveying of grains. This method offers the longest conveying distance and allows for the connection of two or more units to achieve even longer distances, depending on the layout. It typically conveys 1-50 tons of grain per hour.

Inclined Conveying Type: Can convey grains to equipment or silos at different heights within a certain angle range, generally suitable for conveying needs with angles not exceeding 30°. It effectively saves ground space and is a compact alternative to bucket elevators, conveying 0.5-30 tons of grain per hour.

Vertical Conveying Type: Suitable for vertically conveying or lifting grains to the top of silos. It has the smallest footprint and is the ideal choice for lifting grains in space-constrained situations. It can integrate horizontal feeding sections and vertical lifting sections to achieve "L" or "Z" shaped conveying, with a conveying capacity of 0.3-20 tons per hour.

Flexible Screw Conveyor for Grains Parameter Table

| Parameter | Description |

|---|---|

| Pipe Diameter | 100 mm / 150 mm / 200 mm |

| Hose Length | 2 m - 20 m (Customizable) |

| Conveying Distance | 5 m - 20 m |

| Vertical Conveying Height | 0 m - 8 m |

| Conveying Capacity | 1 - 10 t/h (Take grain as an example) |

| Rotation Speed | 20 - 100 rpm (Adjustable) |

| Motor Power | 0.75 kW - 3 kW |

| Power Supply | 380 V / 50 Hz (Three-phase) |

| Material Applicability | Wheat, corn, rice, beans and other grains |

| Pipe Material | Polyurethane hose / Stainless steel spiral blade / Aluminum alloy flange |

Flexible Screw Conveyor for Grains Application Scenarios

Flexible Screw Conveyor for Grains is used in flour mills to transport bulk wheat from the unloading point to the cleaning room, or flour from the collector to the baler; in feed processing plants, it is used for lifting and distributing finished feed after mixing, conveying various pelleted feeds and powders; and for flexible conveying and transfer between silos and between trucks unloading to the top of the silo.

A medium-sized feed mill uses a 100mm diameter flexible screw conveyor with a capacity of 15 tons/hour to vertically lift mixed pelleted feed 6 meters from the bottom mixing outlet, then horizontally bend and convey it 8 meters to the top of the pelleting silo, achieving convenient conveying.

Flexible Screw Conveyor for Grains is suitable for conveying free-flowing pellets such as wheat, corn, rice, beans, and oats. It can also handle malt, feed pellets, and premixes. For materials with extremely high moisture content, prone to clumping, excessively high oil content, or extremely fragile materials, careful selection of equipment type is necessary, as it may lead to blockages, adhesion, or product damage. Grains with high hardness or high moisture content require more wear-resistant hoses and spirals. Flexible spirals are bendable, allowing for flexible design of conveyor lines based on plant layout and silo location. The appropriate feed hopper style, size, and discharge port orientation and connection method should be determined based on the interfaces of upstream and downstream equipment.