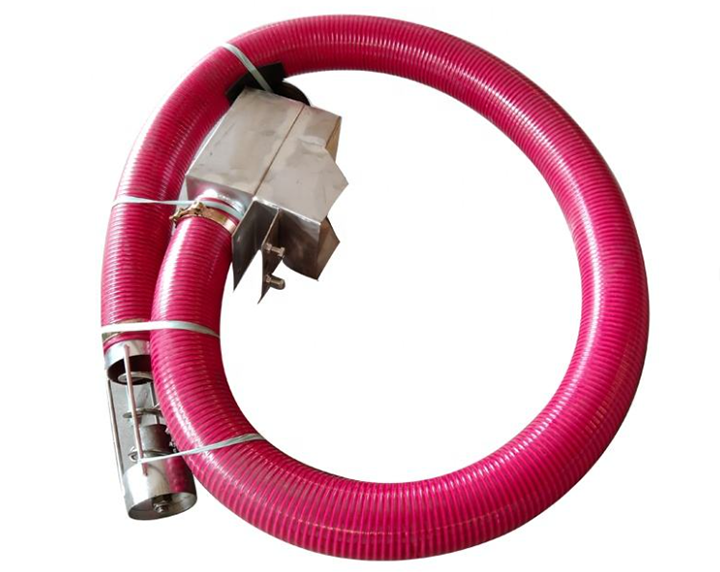

Flexible Screw Conveyor For Plastic Resin

Thursday December-11 2025 13:41:39

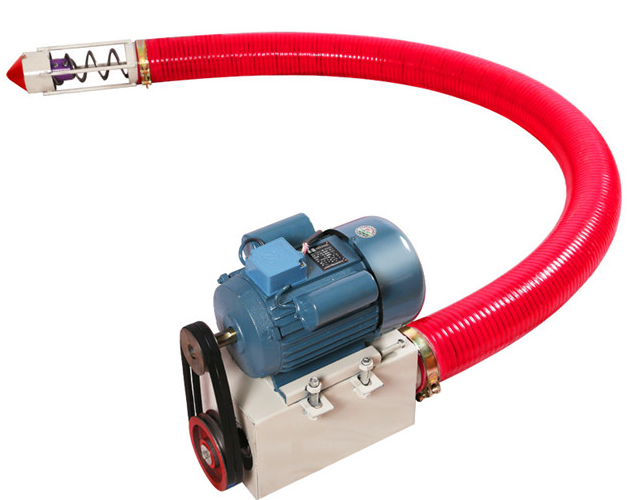

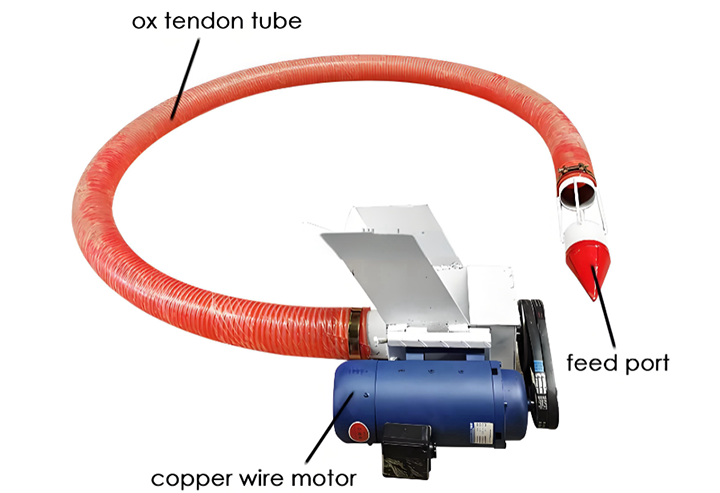

Flexible Screw Conveyor For Plastic Resin delivers plastic resin to the desired location via a curved, enclosed conduit. Plastic resin is typically in granular, powdery, or flake form, and is prone to static electricity and dust generation. Therefore, the spiral conduit is usually made of carbon steel, stainless steel, or an anti-static coating to ensure abrasion resistance and prevent resin adhesion.

Conveying lengths are typically flexibly configured between 3 and 15 meters, with vertical lifting heights up to 6 meters and horizontal conveying distances up to 12 meters. The selection of the bending radius is crucial; too small a radius may lead to blockages or material abrasion. It is recommended that the radius be at least 2.5 times the pipe diameter. Common spiral conduit diameters include 50mm, 63mm, 75mm, 90mm, and 115mm, with a processing capacity of 0.5 to 30 cubic meters of plastic resin per hour, depending on the pipe diameter, rotational speed, and material characteristics.

Flexible Screw Conveyor for Plastic Resin Design

The motor for the Flexible Screw Conveyor for Plastic Resin can be either a three-phase induction motor or an explosion-proof motor; the flexible sleeve is typically made of food-grade or industrial-grade polyurethane or stainless steel braided hose, lined with a smooth, wear-resistant material to reduce friction; the auger is made of wear-resistant spring steel with a smooth surface to prevent material entanglement, and its flexibility ensures it can be bent; the feed inlet can be equipped with a grid or screen to prevent foreign objects or agglomerated materials from entering and damaging the auger; the discharge outlet is typically a fixed or rotatable elbow, which can be directly connected to the top of a dryer, injection molding machine hopper, or mixer.

Advantages of Flexible Screw Conveyor for Plastic Resin

Some resins are prone to wear and buildup in ordinary rigid conveyor pipes, generating static electricity and affecting conveying efficiency. Flexible Screw Conveyor for Plastic Resin gently moves materials without causing strong compression of particles, reducing loss and dust. The machine can bend and bypass obstacles, unlike rigid screws which can only be used in straight lines or with large radii of bend. It can directly convey materials from the hopper to injection molding machines, mixers, etc., without the need for additional conveying equipment or complex modifications. It can convey horizontally, inclined, and vertically over short distances without the need for additional lifting equipment or complex machinery.

Flexible Screw Conveyor for Plastic Resin Type Selection

For fine powder resins with a particle size <0.5mm, a smaller pipe diameter of 50-63mm is recommended to prevent separation and dust generation. For standard granular resins with a particle size of 2-4mm, a pipe diameter of 75-90mm is most commonly used to balance conveying efficiency and energy consumption. Large particles or irregularly shaped resins require a pipe diameter of 90-115mm or even larger to avoid clogging.

In terms of conveying capacity, a 50mm pipe diameter can handle approximately 0.5-1.5 cubic meters of resin per hour, a 63mm pipe diameter increases the conveying capacity to 1-3 cubic meters per hour, a 90mm pipe diameter can convey 4-12 cubic meters per hour, and a 115mm pipe diameter can reach a maximum conveying capacity of 8-30 cubic meters per hour. The conveying capacity is affected by factors such as resin density, moisture content, and system tilt angle. For resins with poor flowability, a design with a larger screw pitch can be selected; while for resins prone to static electricity, models with anti-static coatings or grounding systems should be selected.

Flexible Screw Conveyor for Plastic Resin Price

The price of a flexible screw conveyor varies depending on specifications, materials, and configurations. A standard 100mm diameter, 5-meter length, carbon steel flexible screw conveyor costs approximately $1,500–$2,500 USD. For conveying resins that are static-sensitive or require high cleanliness, stainless steel materials or anti-static coatings are necessary, typically increasing the price to $3,000–$4,500. For solutions with large throughput, conveying distances exceeding 10 meters, or requiring custom hoppers, variable frequency motors, or other special configurations, the price may exceed $6,000.

Flexible Screw Conveyor for Plastic Resin Applications

Plastic resins can be used to manufacture a variety of everyday products, including food packaging boxes, straws, trash cans, flooring, headlight covers, mobile phone cases, and conduits. In the manufacturing process of these products, the Flexible Screw Conveyor for Plastic Resin transports bagged or bulk PE, PP, ABS, and other resin granules from the unloading station to storage silos, dryers, or main production line hoppers; it also transports resins of different colors and types, or additives, to mixers; and it collects crushed scraps and other recycled plastics from collection points to crushers or remixing silos, among other production scenarios.

The Flexible Screw Conveyor for Plastic Resin can be flexibly matched to material characteristics, supporting various conveying requirements in terms of length, height, and bending radius. If a suitable model is not found among the above, you can contact Dahan Machinery for personalized customization of the conveyor pipe length, width, additional functions, etc. As a source manufacturer, we also have price advantages and are a high-quality supplier for various fields such as packaging and agriculture.