Flexible Screw Conveyor For Titanium Dioxide

Friday December-05 2025 17:20:12

Flexible Screw Conveyor For Titanium Dioxide utilizes a flexible screw design suitable for conveying easily dispersed and agglomerated titanium dioxide. Its conveying capacity ranges from 1 to 50 tons per hour. The equipment can cover a horizontal distance of up to 15 meters and lift vertically up to 12 meters, while allowing a maximum tilt angle of 60 degrees. Larger tilt angles can cause material slippage, bottom accumulation, and conveying interruptions. Motor power typically ranges from 0.5 to 15 kilowatts, resulting in low energy consumption. Parts in contact with the material can be treated with food-grade or anti-corrosion coatings to ensure the purity of the titanium dioxide.

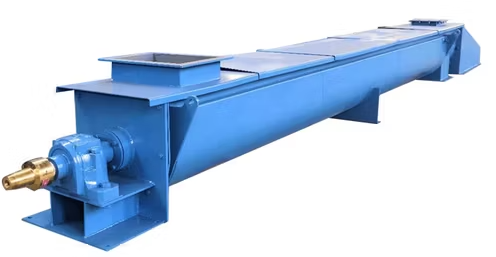

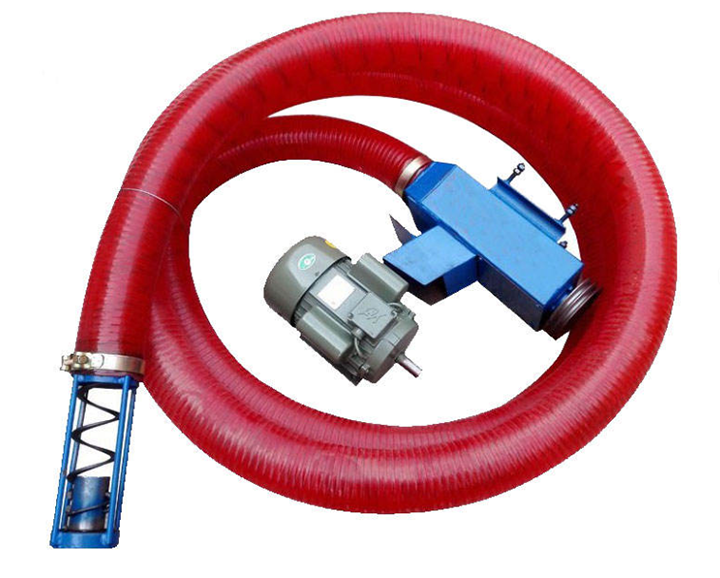

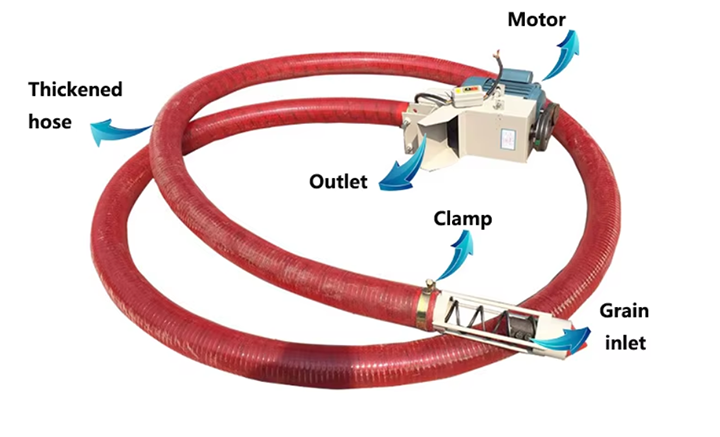

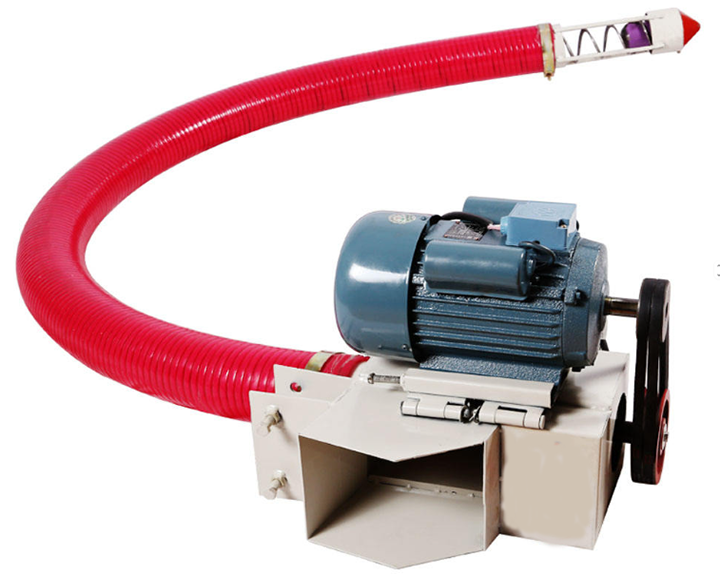

Flexible Screw Conveyor for Titanium Dioxide Structure

The Flexible Screw Conveyor for Titanium Dioxide is constructed from flexible metal wire, allowing for flexible bending and multi-angle conveying routes to suit various site layouts. It typically uses food-grade or industrial-grade nylon tubing, PU tubing, or special plastic tubing with smooth inner walls to reduce titanium dioxide adhesion. The drive system consists of a motor, reducer, and drive head, featuring a compact structure and stable torque output.

Flexible Screw Conveyor for Titanium Dioxide Types

Flexible screw conveyors for titanium dioxide can be categorized into three types based on their hose materials. The different materials offer varying degrees of abrasion resistance and temperature resistance. Details are as follows:

Food-grade Polyurethane:Abrasion-resistant, oil-resistant, and tear-resistant, meeting FDA/USDA standards. Suitable for food-grade or cosmetic-grade titanium dioxide. Temperature range is typically -20℃ to +80℃, with hardness options from 60A to 95A. Suitable for conveying high-purity, contamination-free materials.

Polyethylene or Polypropylene: Lower cost, chemically resistant, smooth surface, easy to clean. Temperature range is generally 0℃ to +60℃. Suitable for industrial-grade titanium dioxide and moderately abrasive environments.

Stainless Steel Braided Reinforced Hose:Externally coated with stainless steel wire mesh, resistant to high pressure and tensile strength. Suitable for long-distance or high-negative-pressure environments. Suitable for systems requiring high mechanical strength or complex wiring.

Flexible Screw Conveyor for Titanium Dioxide Specifications

|

Model |

Conveying pipe diameter |

Conveying length |

Conveying capacity (t/h) |

Motor power (kW) |

|

Φ75 hose machine |

75mm |

3-8 meters |

3-6 |

1.5-3.0 |

|

Φ100 hose machine |

100mm |

3-10 meters |

5-10 |

2.2-4.0 |

|

Φ125 hose machine |

125mm |

4-12 meters |

8-15 |

3.0-5.5 |

Advantages of Flexible Screw Conveyor for Titanium Dioxide

The advantage of the Flexible Screw Conveyor for Titanium Dioxide in conveying titanium dioxide lies in its structural design, which is highly compatible with the properties and conveying requirements of titanium dioxide. It solves pain points such as easy dust generation, equipment wear, and fluctuating flowability, while also meeting the requirements of cleanliness and adaptability to complex working conditions. Specifically:

Titanium dioxide is an ultrafine powder with a large specific surface area and is easily dispersed, causing not only material loss but also pollution of the workshop environment. The flexible screw conveyor uses a fully enclosed pipeline with sealed joints at both ends, ensuring material conveying within a closed space without dust leakage.

The inlet of the Flexible Screw Conveyor for Titanium Dioxide can be sealed and connected to equipment such as silos and packaging machines, and the outlet can be equipped with a sealed discharge device, eliminating any open sections and thus solving the dust generation problem.

The screw has a flexible structure, maintaining contact with the inner wall of the pipeline during operation. Flexible contact, without rigid impact, reduces equipment wear and tear and prevents material breakage, ensuring the original particle size and purity of titanium dioxide.

The flexible screw's helical blades have a continuous spiral structure, generating both pushing and stirring effects during operation, breaking up slightly agglomerated titanium dioxide particles and preventing blockages. The conveying capacity of the flexible screw conveyor is adjusted by changing the screw speed, meeting different needs from small-batch experiments to large-scale production.

Traditional rigid screw conveyors cannot bend, while flexible screw conveyors can bypass obstacles and turn freely, making them more adaptable to complex factory spaces.

Flexible Screw Conveyor for Titanium Dioxide Case Study

In a titanium dioxide production project, titanium dioxide needed to be conveyed from the first-floor storage silo to the third-floor packaging line, a distance of approximately 10 meters with a height difference of 8 meters. Traditional pneumatic conveying systems are energy-intensive and suffer from material grading, while rigid screw conveyors cannot adapt to curved paths. After installing two Flexible Screw Conveyors for Titanium Dioxide with a conveying capacity of 20 tons/hour, the system has been operating stably for over three years, with maintenance frequency reduced by 70%. At a titanium dioxide R&D center, small, flexible screw conveyors are used for material transfer between the laboratory and pilot production line. Their rapid cleaning capabilities allow researchers to complete product changeovers within half an hour, accelerating the R&D process.

Flexible Screw Conveyor for Titanium Dioxide Application Scenarios

In upstream processes, the Flexible Screw Conveyor for Titanium Dioxide can be used to transport titanium dioxide from storage silos to reactors or mixing equipment. During production, it is suitable for cooling and conveying calcined products and transferring surface-treated titanium dioxide. Downstream, it is used to supply finished titanium dioxide to packaging machines, tablet presses, or bulk trucks.

With its unique flexible design, enclosed conveying environment, and excellent adaptability, the Flexible Screw Conveyor for Titanium Dioxide has become a reliable choice for material handling in the titanium dioxide industry. Dahan Machinery, as a manufacturer of titanium dioxide conveying equipment, not only provides standard-compliant material certifications but also recommends suitable configurations based on the specific material's bulk density, flowability, corrosiveness, and other characteristics, offering standardized manufacturing or non-standard customization to meet diverse needs.