Flexible screw conveyor for wheat

Saturday September-28 2024 10:30:40

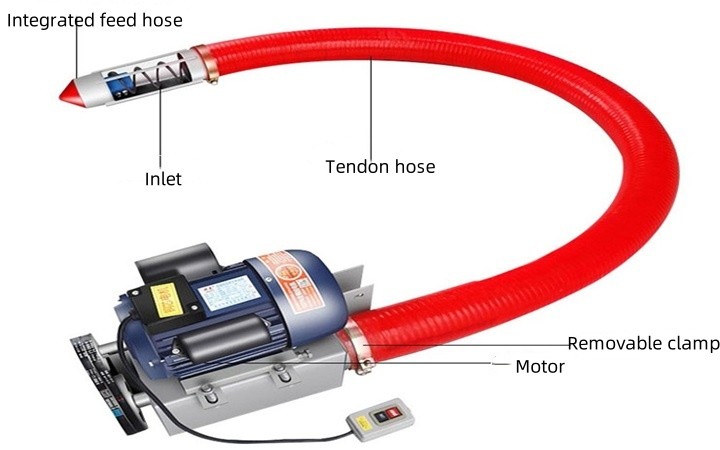

Flexible screw conveyor for wheat is a kind of equipment specially used for conveying granular materials such as wheat. It has been widely used in grain processing, warehousing and other fields due to its flexibility, high efficiency and reliability.

1.Principle of Wheat Flexible Screw Conveyor

Flexible screw conveyor for wheat is an efficient and flexible conveying equipment, widely used in grain processing, warehousing and other industries. Its working principle is relatively simple, but it can achieve efficient material transportation. The following is its principle:

Rotation of spiral blades: The core component of the flexible screw conveyor is the flexible spiral blade. When the spiral blade drive shaft rotates, the blade rotates in the conveying trough.

Material push: The rotating spiral blade lifts the material (such as wheat) and pushes it forward. Due to the friction between the material and the wall of the conveying trough, the material can only move forward with the spiral blade, and will not rotate with the blade.

Continuous conveying: As the spiral blade continues to rotate, the material is continuously conveyed from the feed port to the discharge port.

2.Application of Wheat Flexible Screw Conveyor

Flexible screw conveyor for wheat are widely used in the wheat processing industry. Here are some application scenarios of wheat flexible screw conveyors:

Wheat processing production line: In wheat processing production lines, wheat flexible screw conveyors are often used to transport wheat particles from warehouses to processing equipment such as cleaning, grinding, drying, or to transport processed wheat powder to packaging areas.

Warehousing and logistics: Wheat flexible screw conveyors can also be used in warehouse logistics systems to help transport wheat particles from warehouses to loading and unloading areas or other equipment to improve material handling efficiency.

Food processing factories: In food processing factories, wheat flexible screw conveyors can be used to transport wheat particles to different processing links such as flour production lines and bread production lines.

Agricultural field: In the agricultural field, wheat flexible screw conveyors can also be used to transport wheat particles to different processing equipment, such as equipment for feed processing or seed processing equipment.

Packaging industry: Wheat flexible screw conveyors can also be used to transport wheat powder to packaging machinery to help automate the packaging process and improve production efficiency.

3.Advantages of Wheat Flexible Screw Conveyor

Wheat flexible screw conveyor has many advantages that make it widely used in wheat processing and other industries. Here are some advantages of wheat flexible screw conveyor:

Flexibility: Wheat flexible screw conveyor adopts flexible pipe design, which can bend and adjust the shape as needed to adapt to different production scenarios and layout requirements.

Space saving: Due to the characteristics of flexible pipe, wheat flexible screw conveyor can be flexibly arranged in a limited space, saving production space, and can convey materials along complex paths.

High conveying efficiency: The spiral blade design of the screw conveyor can efficiently push wheat particles along the pipeline, reduce energy consumption and improve production efficiency.

Wide applicability: In addition to wheat particles, wheat flexible screw conveyor can also convey various granular materials such as powder, granules, etc., which is suitable for the production needs of many industries.

Cost-effectiveness: Wheat flexible screw conveyor can reduce labor costs, improve production efficiency, and reduce energy consumption, thus bringing cost-effectiveness.

Reliability: The screw conveyor has a simple structure, reliable operation, low maintenance cost and a long service life.

4.Selection suggestions for wheat flexible screw conveyor

When choosing a flexible screw conveyor for wheat, there are several factors to consider to ensure that the right equipment is selected. Here are some recommended selection points:

Processing capacity: Determine the required wheat conveying volume based on production needs. Make sure the selected flexible screw conveyor for wheat can meet the expected processing capacity.

Conveying distance: Consider where the wheat needs to be transported from and to, and determine the conveying distance to select a conveyor of appropriate length.

Material properties: Consider the material properties of wheat such as density, particle size, viscosity, etc., and select a conveyor model that suits these characteristics.

Layout requirements: Consider the layout and space limitations of the production site, and select a suitable flexible screw conveyor to meet actual needs.

Environmental requirements: Consider factors such as temperature and humidity in the environment where the flexible screw conveyor for wheat is located, and select equipment that can adapt to the environment.

Maintenance and cleaning: Consider the maintenance and cleaning requirements of the equipment, and select a design that is easy to maintain and clean to ensure long-term stable operation of the equipment.

In short, the wheat flexible screw conveyor plays an important role in the grain processing industry with its unique advantages. When purchasing, you need to consider various factors and choose the equipment that suits your needs.