Fly ash flexible screw conveyor

Friday January-09 2026 17:56:28

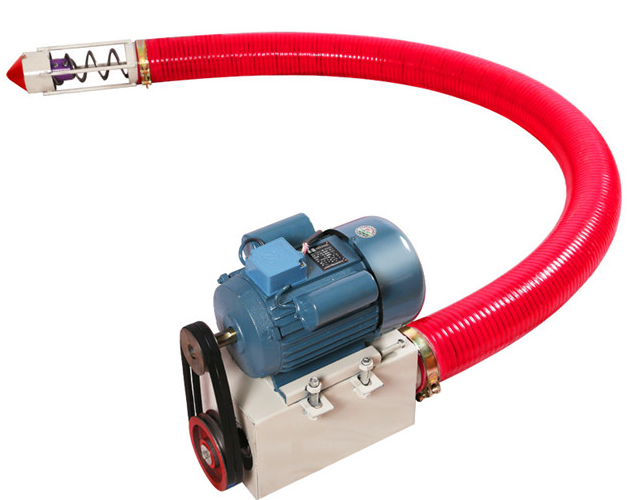

Fly ash flexible screw conveyor uses an internally rotating helical spring to flexibly and dust-free transport fly ash within a sealed, wear-resistant flexible hose. Its single-unit conveying capacity is typically 1-30 cubic meters per hour, with a conveying distance of 15 meters horizontally or 6 meters vertically, and it can achieve multi-angle bending layouts from 0-90 degrees. Handheld or dual-head models are available to meet different application needs. For fly ash with fineness and slight abrasiveness, the screw can be made of spring steel or alloy steel, and the conveying pipe can be made of carbon steel, stainless steel, or wear-resistant plastic to make the machine more wear-resistant.

How does the Fly ash flexible screw conveyor work?

After starting, the motor drives the flexible helical steel wire to rotate in the pipe. The fly ash is filled between the helical blades and the pipe wall. As the screw rotates, the material is continuously pushed forward by the combined action of axial thrust and friction. The fly ash is not thrown up, but rather slowly rolls and slides forward along the inner wall of the pipe, flowing in a spiral motion. When the conveying pipeline bends or tilts, the flexible screw adapts to the pipeline shape while maintaining continuous pushing, allowing fly ash to smoothly pass through bends. Finally, it is conveyed out from the outlet.

What are the advantages of a fly ash flexible screw conveyor?

Fly ash flexible screw conveyors offer advantages such as preventing dust spillage, preventing fly ash from getting damp, adjustable speed, easy installation, and flexible angles.

The outer shell of the fly ash flexible screw conveyor is a flexible tube, and the screw shaft is also flexible. It can bypass obstacles, tilt upwards, downwards, or bend horizontally for installation, eliminating the need for multiple devices to be joined at right angles like traditional rigid screw conveyors, saving space and installation costs.

Flexible screw conveyors are typically controlled by variable frequency motors, enabling variable speed conveying. By adjusting the speed, workers can control the amount of fly ash added, ensuring consistent quality of concrete or bricks.

When the central screw shaft of the flexible screw conveyor rotates, in addition to pushing the material forward, it also provides a certain amount of vibration and kneading action, preventing fly ash bridging and blockage. It handles slightly damp or fibrous fly ash mixtures well.

Flexible screw conveyors typically only require loosening a few bolts to pull out the screw tube. When changing the type of material being conveyed or performing regular cleaning, maintenance personnel can quickly remove fly ash accumulated in corners, reducing the risk of equipment corrosion and aging.

Types of Fly Ash Flexible Screw Conveyors

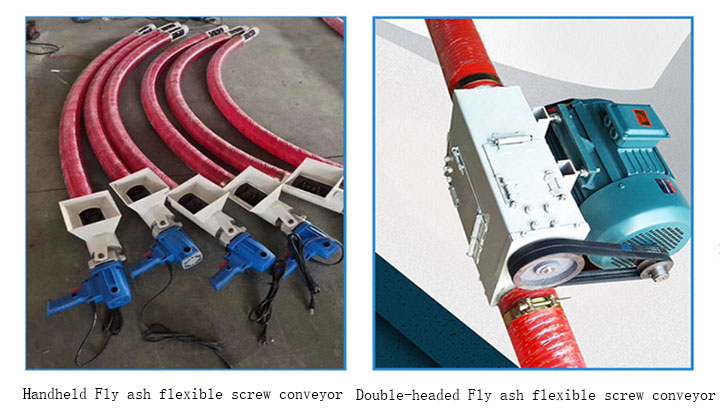

The type of fly ash flexible screw conveyor can be selected based on the actual application of the fly ash being conveyed: handheld or dual-head type. Each type has its own characteristics, which are described below.

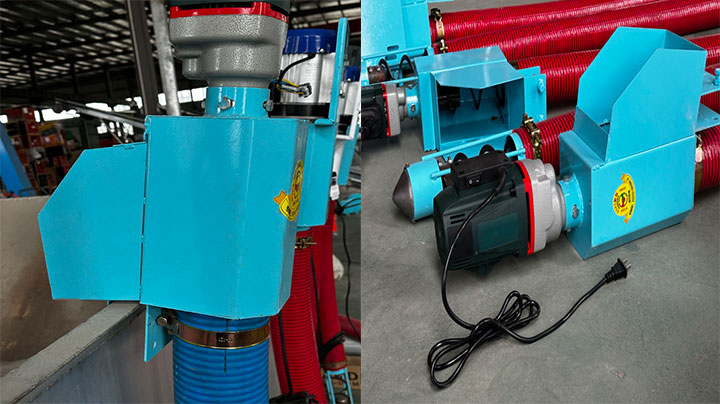

Handheld types are mostly used for temporary or small-batch fly ash transfer. The equipment is lightweight and can be moved and quickly positioned by a single person. Common conveying lengths are approximately 1–4 meters, suitable for point-to-point feeding. The motor is generally a 0.75–2.2 kW single-phase or three-phase geared motor, with low speed, fast start-up, and simple maintenance. Installation methods are mostly ground support or movable brackets.

Dual-head types are suitable for fixed installations and continuous production lines, enabling bidirectional or segmented conveying. The conveying length is typically 5–12 meters, with intermediate support frames to prevent bending. The motor is a 3–7.5 kW three-phase geared motor, offering higher torque and suitable for high-load, long-term operation. It can be mounted on a fixed base or with factory-installed pipe connections for connection to silos or boilers.

Fly ash flexible screw conveyor parameters

| Parameter Category | Parameter Range |

| Pipe Diameter (mm) | 40 / 50 / 65 / 75 / 90 / 110 / 130 |

| Conveying Capacity (m³/h) | 0.2 – 25 |

| Conveying Distance (m) |

Horizontal: 2 – 20 Vertical: 2 – 8 |

| Working Pressure (MPa) | ≤ 0.3 (Low pressure or micro-pressure) |

| Hose Material | Food-grade PU / Industrial-grade PU / Rubber composite tube |

| Hose Service Life | 1 – 5 years |

| Screw Material | Spring steel / Stainless steel (304/316) |

| Screw Rotating Speed (rpm) | 300 – 1400 |

| Driving Power (kW) | 0.75 – 11 |

| Conveying Angle | 0° – 90° |

| Working Temperature (℃) | -10 ~ +60 (Standard PU) |

Applications of the Fly ash flexible screw conveyor

The Fly ash flexible screw conveyor can transport fly ash from the ash collection hopper to the ash storage silo, or from the ash storage silo to the mixer. It can uniformly and continuously feed fly ash from large silos into weighing systems or concrete mixers.

Fly ash, as an industrial solid waste, can be used appropriately to improve concrete performance, for roadbed filling, soil improvement, and the manufacture of fly ash bricks, among other applications. The Fly ash flexible screw conveyor transports fly ash to where it is needed in these applications.