Grain suction machine type material discharge equipment

Saturday May-24 2025 16:39:03

What is a grain suction machine type material discharge equipment

Grain suction machine type material discharge equipment is a machine specially designed for efficient handling of grains, taking into full consideration the physical properties and discharge requirements of grains. Grains usually have a small particle diameter and a light density, and are easily affected by environmental factors. Therefore, during the discharge process, the equipment must ensure that the material is not damaged.

The equipment uses the principle of negative pressure suction to suck grains from storage bins or transport vehicles through suction pipes, reducing the loss and waste of materials during the discharge process. Its efficient conveying system can quickly transfer grains to designated locations to ensure the continuity and efficiency of operations.

Applicable materials for grain suction machine type discharge equipment

Grain suction machine type discharge equipment is mainly suitable for conveying bulk materials in granular, powdery or small blocks. Its working principle is to convey materials in a closed pipe through the negative pressure (suction) or positive pressure (blowing) of the airflow.

All kinds of grains and beans, oilseeds and derivatives, animal feed raw materials and finished feed

Fine bulk, certain chemical materials (such as alumina, soda ash, etc.)

Other powdered or small granular materials (flour, sugar, salt, plastic granules, etc.)

Classification of grain suction machine type discharge equipment

There are three common types of grain suction machine type discharge equipment: handheld grain suction machine, vehicle-mounted grain suction machine, hose grain suction machine, covering its basic structure, applicable scenarios, conveying capacity and other core information:

|

Classification name |

Picture |

Structural features |

Applicable occasions |

Conveying capacity |

Advantages |

Limitations |

|

Handheld grain suction machine |

|

Portable design, handheld operation of the suction port |

Small-scale operation, grain warehouse cleaning, farmer's household grain bagging, temporary transportation |

Generally 1 to 5 tons/hour |

Small size, operation Flexible, low-cost, easy to move |

Short conveying distance, not suitable for continuous large-scale operations |

|

Car-mounted grain suction machine |

|

Install the grain suction system on the transport vehicle |

Unloading of bulk grain transport vehicles, loading of grain depots, long-distance discharge |

10-50 tons/hour |

High degree of automation, suitable for large-scale operations, strong adaptability |

High cost, dependent on vehicle power, requires professional operators |

|

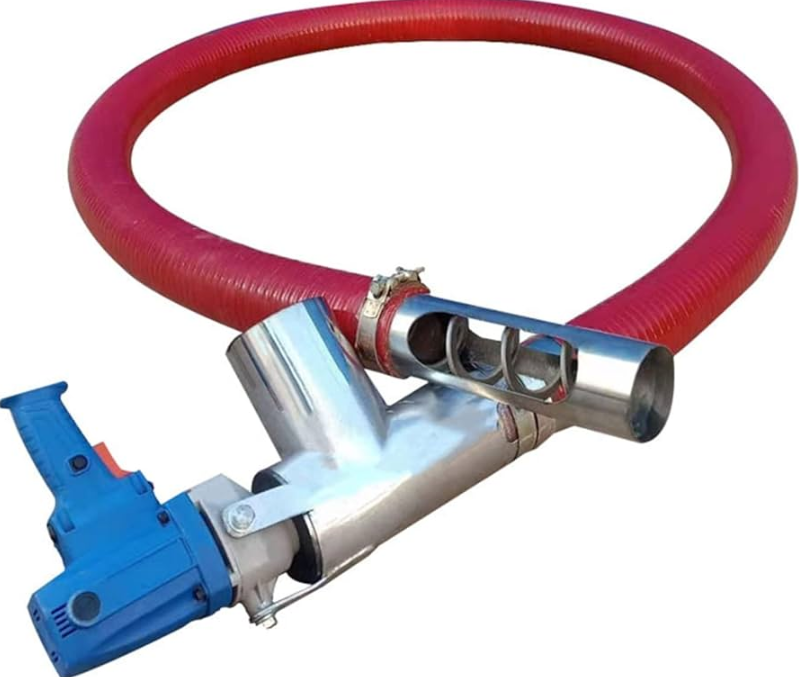

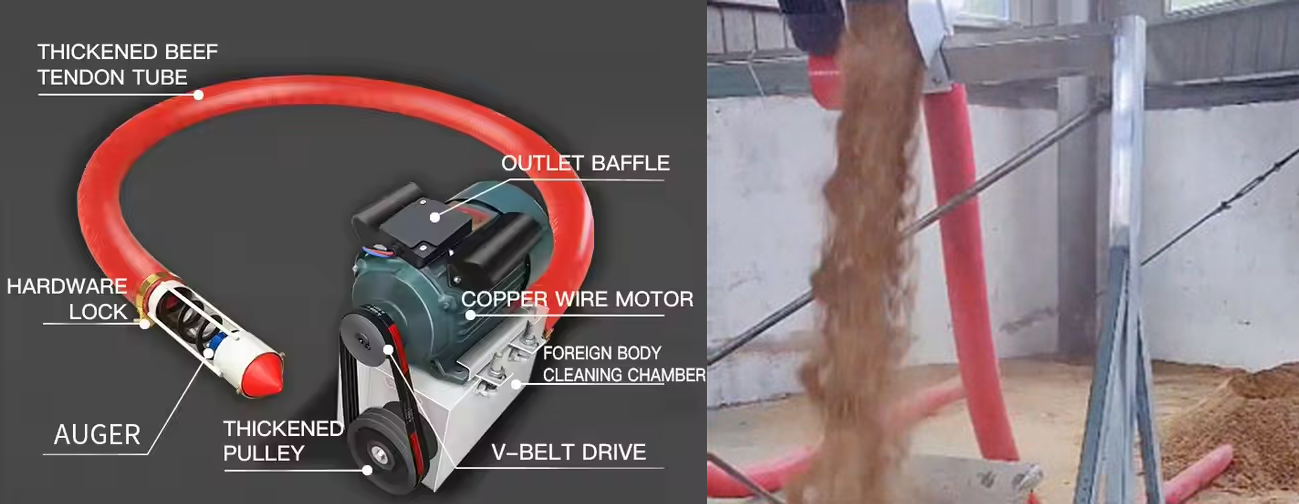

Hose grain suction machine |

|

Use flexible spiral to suck grain through a hose |

Suction of ground grain piles, cleaning of the bottom of the warehouse, loading before packaging, etc. |

5-20 tons/hour |

Flexible conveying direction, strong adaptability, multi-point grain suction, can be connected to hoppers or packaging equipment |

Fast wear, large particles or impurities are easy to clog |

Brief description:

Handheld: suitable for family farmers and small grain warehouses, small size but low efficiency.

Car-mounted: more common in large grain depots and transportation operations, especially suitable for discharge grain from vehicles without pits or unable to dump.

Hose type: suitable for diversified and complex space operations, such as warehouse corners and silo discharge ports.

What can a grain suction machine unloader be used for?

Grain suction machine unloaders are widely used in grain storage, processing, and transportation, and are particularly suitable for the spatial transfer, fixed-point loading, and closed discharge of bulk grain. In agricultural production, hose-type or handheld suction machines are suitable for farmers or small grain stations to suck grain from simple grain storage containers into transport vehicles or packaging equipment, especially for places with low material stacking heights or limited working space. In the vehicle-mounted grain suction system, the equipment is installed on the transport vehicle to quickly suck grain from the ground or storage area and load it onto the vehicle. It is often used in grain purchasing stations, agricultural and sideline product distribution centers, and large-scale grain trade logistics. The equipment can adapt to suction paths of different lengths and curvatures, and is suitable for cross-floor, wall-penetrating pipelines, or long-distance arrangements.

Overall, grain suction machine type material discharge equipments can protect the integrity of grain to the greatest extent. Because grains are fragile and have different moisture contents, traditional mechanical conveying (such as screw conveyors) may cause breakage and dust. The suction machine reduces mechanical extrusion and friction through the gentle action of airflow, significantly reducing the breakage rate of grains during transportation. In the discharge process, whether it is direct loading, storage, or transfer to processing equipment, it can achieve fast and clean operations, which is particularly suitable for frequent batch transfer, storage cleaning and process processing.