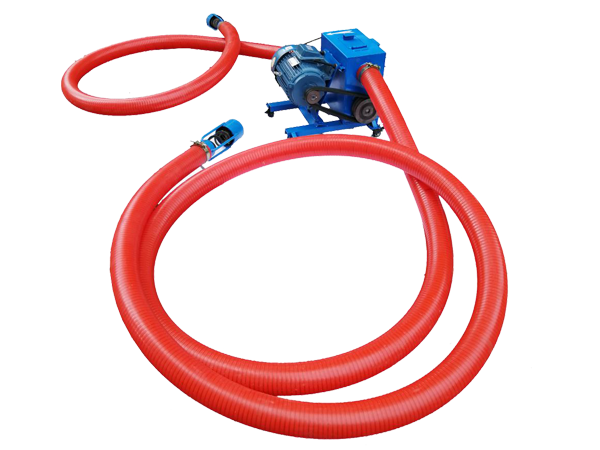

Graphite powder Flexible Screw Conveyor

Tuesday January-20 2026 17:54:48

Graphite powder Flexible Screw Conveyor is suitable for conveying powdered and granular graphite powder. Its conveying capacity varies with screw speed, pipe diameter, and material density, generally ranging from 100 to 2000 kg/h for continuous graphite powder conveying. The conveying distance and route are flexible, adaptable to straight lines, curves, and multi-point arrangements. Standard conveying lengths can reach 20-30 meters, with an inclination angle generally not exceeding 25°, although special designs can accommodate a maximum inclination angle of 40°. The equipment is suitable for conveying wear-resistant and conductive materials such as graphite powder. It has high requirements for the operating environment and should avoid high-temperature, humid, and flammable/explosive locations.

Graphite Powder Flexible Screw Conveyor Manual

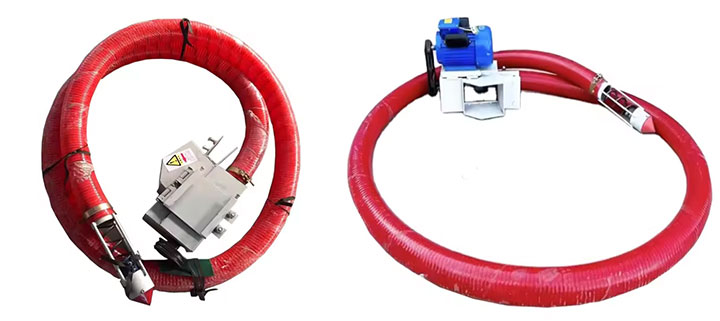

The Graphite Powder Flexible Screw Conveyor consists of a flexible screw mandrel, wear-resistant conveying pipe, drive unit, inlet and outlet ports, and support structure. The spiral mandrel uses wear-resistant steel with a special surface coating to reduce graphite powder adhesion; the smooth inner polymer sleeve prevents electrostatic adsorption of graphite powder; the stepless speed-regulating motor can adapt to different conveying volumes; the specially designed leak-proof interface ensures sealing; and the adjustable support allows for horizontal, inclined, and vertical conveying arrangements. Before starting the equipment, check that all interfaces are properly sealed. During startup, place the feed inlet in the graphite powder and then turn on the switch. Avoid frequent movement of the pipeline during operation to prevent congestion in the graphite powder conveying process.

Benefits of the Graphite Powder Flexible Screw Conveyor

Graphite powder dust is extremely fine and easily dispersed. Ordinary belt conveyors or open conveyors easily generate dust, polluting the environment and causing material loss and equipment contamination. The Graphite Powder Flexible Screw Conveyor provides a closed conveying system, preventing graphite powder from escaping. Graphite powder is highly lubricating but has unstable flow, easily slipping and bridging in the hopper. The equipment can continuously agitate the material in the pipeline during graphite powder conveying without clogging. Graphite powder is highly conductive, potentially causing short circuits or static electricity in dusty environments. The equipment's pipelines are sealed, and the conveying process is gentle. If graphite powder is contaminated with impurities, many applications will be rendered unusable. The Graphite powder Flexible Screw Conveyor prevents contamination with other materials, reducing cross-contamination.

Graphite powder Flexible Screw Conveyor Parameter Table

| Model | Capacity (t/h) | Inner Ø (mm) | Length (m) | Speed (rpm) | Motor (kW) | Explosion-Proof | Material |

| FSHC-80 | 0.5-2.0 | 80 | 5-10 | 1400 | 0.75-1.1 | Ex d IIB T4 | Q235 / SUS304 |

| FSHC-100 | 1.0-3.5 | 100 | 5-15 | 1400 | 1.1-1.5 | Ex d IIB T4 | Q235 / SUS304 |

| FSHC-125 | 2.0-5.0 | 125 | 5-20 | 960 | 1.5-2.2 | Ex d IIB T4 | Q235 / SUS304 |

| FSHC-150 | 3.0-8.0 | 150 | 5-20 | 960 | 2.2-3.7 | Ex d IIB T4 | Q235 / SUS304 |

| FSHC-200 | 6.0-12.0 | 200 | 5-25 | 960 | 3.7-5.5 | Ex d IIB T4 | Q235 / SUS304 |

| FSHC-250 | 10.0-18.0 | 250 | 5-30 | 720 | 5.5-7.5 | Ex d IIB T4 | Q235 / SUS316L |

| FSHC-300 | 15.0-25.0 | 300 | 5-30 | 720 | 7.5-11 | Ex d IIB T4 | Q235 / SUS316L |

Graphite powder flexible screw conveyor for sale

The price of the Graphite powder Flexible Screw Conveyor varies depending on the equipment length. Short-distance models (less than 3 meters) cost approximately $1200 to $3100, suitable for small-batch, short-distance conveying. Equipment with conveying distances between 3 and 10 meters typically costs around $3200 to $5500; this length is common for inter-workshop transfers. For long-distance conveying of 10 to 20 meters, the price is approximately $5,500 to $10,000, requiring a more powerful motor and a reinforced chassis structure. Besides length, materials, motor power, and control systems also affect the final quote.

Graphite Powder Flexible Screw Conveyor Case Study

A lithium battery company's graphite powder conveying workshop faced challenges such as dust pollution, high static electricity risks, dense equipment, and complex conveying routes. After adopting a customized Graphite powder flexible screw conveyor, the company controlled dust leakage to below 0.1 mg/m³ thanks to the equipment's fully enclosed piping. The machine body is made of anti-static material and equipped with a grounding device to release static electricity buildup and avoid the risk of explosion. The flexible hose design allows for cross-area conveying of 5 meters at a 60° angle without altering the existing factory layout. The equipment operates continuously in alternating indoor ambient temperature and outdoor -5°C low-temperature environments, achieving over 8,000 hours of trouble-free operation, ensuring operator health and production safety while saving space through a compact layout.

The Graphite Powder Flexible Screw Conveyor can be used in various graphite powder production applications. For example, in electrode preparation, it ensures precise proportions by conveying graphite powder, preventing impurities from affecting battery performance. Alternatively, it can quantitatively feed graphite powder into reactors or grinding mills, seamlessly integrating with automated production lines. When selecting equipment, components such as explosion-proof motors can be added to better convey graphite powders with different properties.