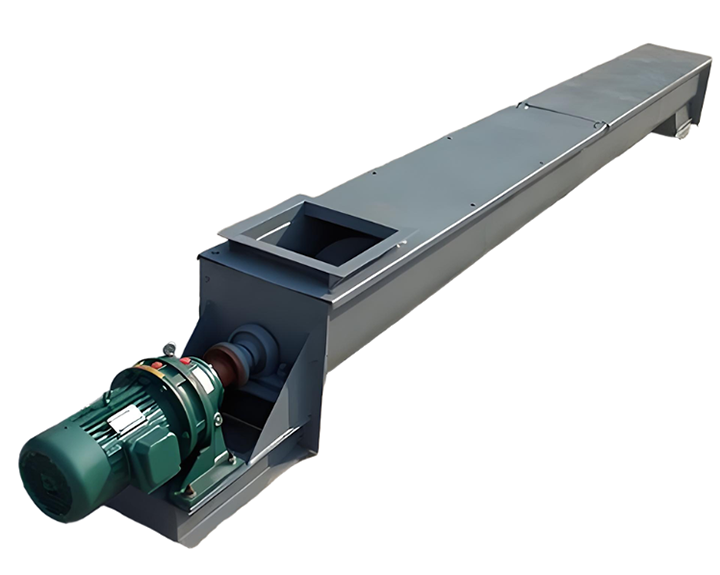

High Temperature Screw Conveyor for Powder Delivery

Thursday November-20 2025 16:15:17

In some industries, it is often necessary to transport powdered materials in high-temperature environments. Ordinary conveying equipment is prone to deformation, wear, and seal failure under such conditions. High Temperature Screw Conveyor for Powder Delivery, however, ensures structural strength by using high-temperature resistant special alloy steel for its core components. In terms of structural design, it typically employs high-temperature bearings, thermal expansion compensation structures, and auxiliary cooling systems to ensure the equipment operates reliably at high temperatures. These conveyors can typically withstand continuous high temperatures from 200°C to 800°C, and some special designs can even handle instantaneous temperatures up to 1000°C. In terms of conveying capacity, it can be customized according to process requirements, ranging from 2 to 15 tons per hour.

High Temperature Screw Conveyor for Powder Delivery Design

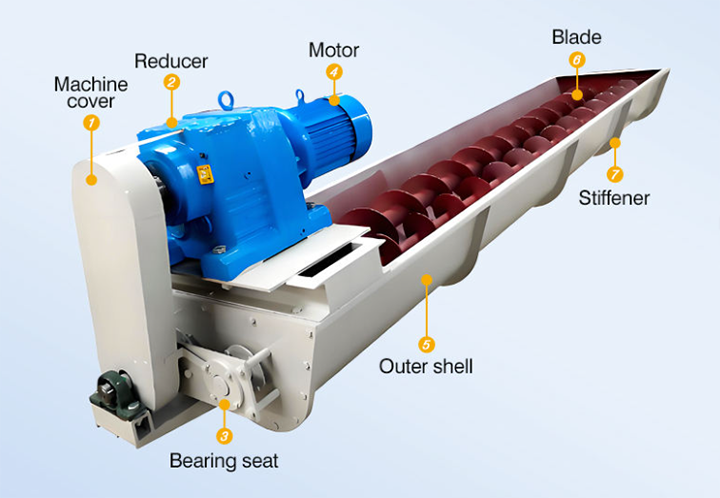

While the structure of the High Temperature Screw Conveyor for Powder Delivery is similar to that of a traditional screw conveyor, the design of each component incorporates high-temperature resistance considerations. It mainly consists of a drive unit, inlet, U-shaped trough shell, spiral blades, intermediate hanger bearings, outlet, and tail-end bearing housing.

Spiral Blades and Shaft: As core conveying components, the blades and shaft are in direct contact with the high-temperature powder. They are made of heat-resistant steel to ensure sufficient strength and creep resistance at high temperatures. The blade surface can be hardened to enhance its wear resistance.

Shell: The conveying trough is typically designed with a double-layer jacket structure, allowing cooling water or air to pass through, forming an effective heat barrier to protect the external structure and operator safety, while reducing the impact of heat loss on the production environment.

Bearing System: The drive-end bearing is kept as far away from the high-temperature zone as possible and may be equipped with a cooling jacket. The tail-end bearing adopts a floating or hinged design as a thermal expansion compensation point, allowing the entire spiral shaft to move freely when heated, avoiding shaft bending or bearing seizure due to thermal stress. Intermediate hanger bearings are essential for long-distance conveying; they also use high-temperature resistant materials and self-lubricating designs, and their number is minimized to reduce potential failure points. Sealing System: Employs special high-temperature resistant sealing materials such as ceramic fibers to prevent powder leakage and air ingress, ensuring system tightness.

High Temperature Screw Conveyor for Powder Delivery Types

In high-temperature powder conveying scenarios, the material selection of the High Temperature Screw Conveyor for Powder Delivery directly determines the equipment's heat resistance, wear resistance, service life, and cost. It can be mainly divided into the following categories:

Carbon Steel

This is the most common and economical choice, such as Q235 steel. Its advantages include low cost, mature processing technology, and high strength. However, under high-temperature environments, carbon steel is extremely prone to oxidation and rust, forming oxide scale that flakes off and contaminates powdery materials. Simultaneously, its strength and hardness decrease, making it unsuitable for conditions with strict cleanliness requirements or long-term exposure to temperatures exceeding 350℃. It is generally only used in areas with less stringent temperature requirements or non-core high-temperature sections.

Stainless Steel

This is the mainstream choice for high-temperature powder conveying, especially represented by 304, 316, 321, and 310S. 304/316 Stainless Steel: Offers good corrosion resistance and moderate heat resistance, suitable for applications below 500℃. 316, containing molybdenum, exhibits enhanced resistance to pitting corrosion.

321 Stainless Steel: With the addition of titanium, it possesses excellent resistance to intergranular corrosion and can withstand temperatures up to approximately 800℃, making it a common high-temperature grade.

310S Stainless Steel: An austenitic chromium-nickel stainless steel with excellent oxidation resistance and creep strength, it is a professional high-temperature material capable of withstanding continuous operating temperatures up to 1150℃, making it the first choice for extreme high-temperature environments, but with a higher cost.

Special Alloys

For powders requiring even higher temperatures or exhibiting greater abrasion or corrosion, special high-temperature alloys such as Inconel alloys are used, or nitriding or spraying with hard alloy coatings such as tungsten carbide are applied to the carbon steel surface to significantly improve the surface's heat resistance, wear resistance, and corrosion resistance while maintaining core strength.

What are the applications of a High Temperature Screw Conveyor for Powder Delivery?

The High Temperature Screw Conveyor for Powder Delivery can be used in various industries, including cement, metallurgy, chemicals, and food. It is used for conveying high-temperature clinker at the tail of rotary kilns and after cooling; conveying sintered ore, high-temperature alumina powder, and metal powders; in catalyst production, carbon black conveying, and high-temperature discharge after plastic granule drying; conveying raw materials in the high-temperature sintering process of lithium battery positive and negative electrode materials; and conveying high-temperature flour, starch, or other powdered food additives after drying.

The High Temperature Screw Conveyor for Powder Delivery solves the core pain points in high-temperature powder conveying, ensuring production continuity, safety, and economy. Conveying highly abrasive powders requires thicker or more wear-resistant blade materials; viscous powders require larger blade spacing and faster rotation speeds to prevent clogging. Horizontal, inclined, or vertical conveying can be selected depending on the conveying distance. Dahan Vibration Machinery can customize the most suitable model for you, including determining the screw diameter, screw speed, motor power, special material list, and optimized cooling and thermal compensation solutions.