Hopper Feeder Range For Clinker Loading

Tuesday May-27 2025 14:45:59

The hopper feeder range for clinker loading is a type of feeding equipment designed for the characteristics of cement clinker such as high temperature, high hardness, and different particle sizes. Its main function is to transport the clinker stored in the hopper to the next process in a stable and controllable manner, such as conveyors, loading and shipping systems or storage bins. After cooling, clinker still has a certain temperature, often in block or granular form, and has a certain abrasiveness. The hopper feeder range achieves buffering, uniform speed, and quantitative delivery of materials through different methods such as plate chain, vibration, and spiral, avoiding material impact blockage or excessive delivery, and ensuring the continuous operation of the entire delivery process.

What are the core functions of the hopper feeder range for clinker loading?

The hopper feeder is a key equipment for achieving continuous and uniform material delivery in industrial production, especially in the clinker loading scenario, and its core value is reflected in three aspects.

Stable delivery: through vibration, gravity or mechanical transmission, ensure the smooth transition of materials from the silo to the downstream equipment to avoid blockage or interruption.

Controllable flow: supports stepless adjustment (such as vibration frequency, hopper speed) to meet different production rhythm requirements.

Strong adaptability: can handle powdery, granular, and small block materials (such as cement clinker), and some models support high temperature or corrosive materials.

What are the classifications of the hopper feeder range for clinker loading?

1.Plate feeder (heavy/medium)

The motor drives the sprocket to drive the chain and the slats installed on the chain to run, and the clinker in the hopper is transported from the feed port to the discharge port to realize the feeding process.

Scope of application: large pieces of high-temperature clinker

Structural features: equipped with a hopper or silo, and the material is transported forward by dragging the plate chain; strong bearing capacity, suitable for clinker above 150℃; variable frequency speed regulation can be set to achieve quantitative feeding.

Common parameters: Feeding particle size: ≤300mm; conveying capacity: 20~600 t/h; chain plate width: 500~1600 mm

Applicable scenarios: commonly used for clinker loading and conveying in mining, cement, construction and other industries, especially before the primary crushing equipment, it can continuously and evenly convey large pieces of material, and can control the feeding amount to match the processing capacity of the subsequent crushing and screening production line.

2.Vibrating feeder (electromagnetic or motor vibration)

The vibration force generated by the vibration motor is used to make the clinker in the hopper flow evenly to the discharge port under the action of vibration, thereby realizing the feeding function.

Scope of application: clinker powder or fine particles with smaller particle size

Structural features: The material is moved forward by driving the trough through the vibration source; equipped with a hopper or buffer bin, suitable for short-distance feeding; the feeding rate can be accurately adjusted, suitable for batching control.

Common parameters: feeding particle size: ≤120mm; conveying capacity: 5~150 t/h

3.Belt feeder

The belt feeder uses a belt (or belt) as a traction and load-bearing component, and drives the belt to run through a driving roller. The material falls from the hopper onto the belt and is transported to the specified position by the belt. The feeding amount is controlled by adjusting the belt speed or the hopper gate opening.

Scope of application: continuous clinker feeding process

Structural features: Through frequency conversion speed regulation or gate control, the feeding speed and flow rate can be accurately adjusted, and powder, granular and small block clinker (particle size is usually ≤100mm) can be conveyed, suitable for wet or dry materials.

Common parameters: belt width: 500~1400 mm; conveying capacity: 5~300 t/h

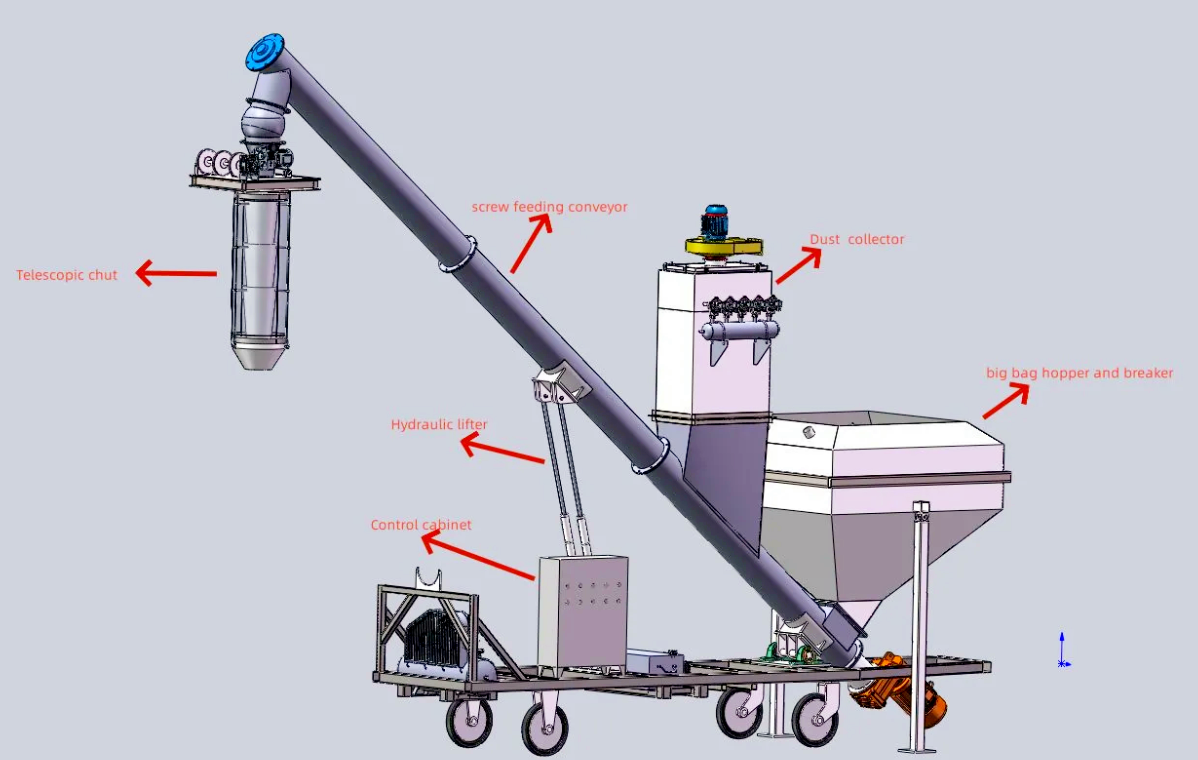

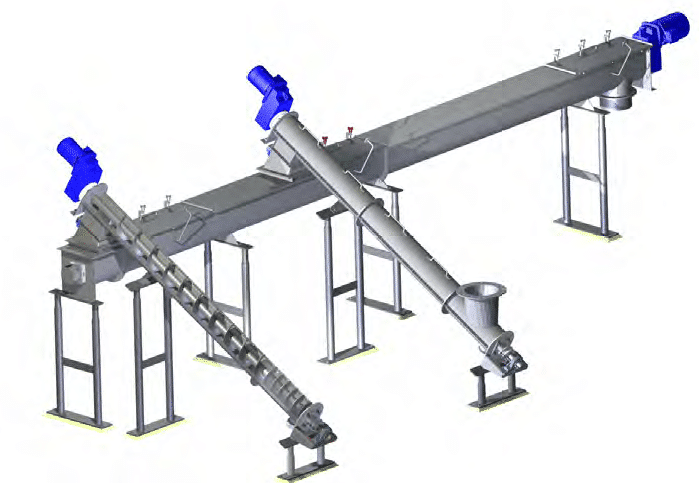

IV. Screw feeder (closed type)

The screw feeder is driven by the drive device to rotate the screw shaft, and the spiral blades push the clinker in the hopper to move along the axial direction of the casing and discharge from the discharge port. Quantitative feeding is achieved by controlling the screw speed or adjusting the feed gate.

Scope of application: Powdered or granular clinker, closed conveying is required

Structural features: Multiple matching hoppers are used to achieve horizontal or small angle tilt feeding; basically sealed during the conveying process to reduce dust; the spiral body can be made of wear-resistant alloy or stainless steel.

Common parameters: Conveying capacity: 1~80 m³/h; Screw diameter: 100~500 mm; Conveying distance: up to 20 m

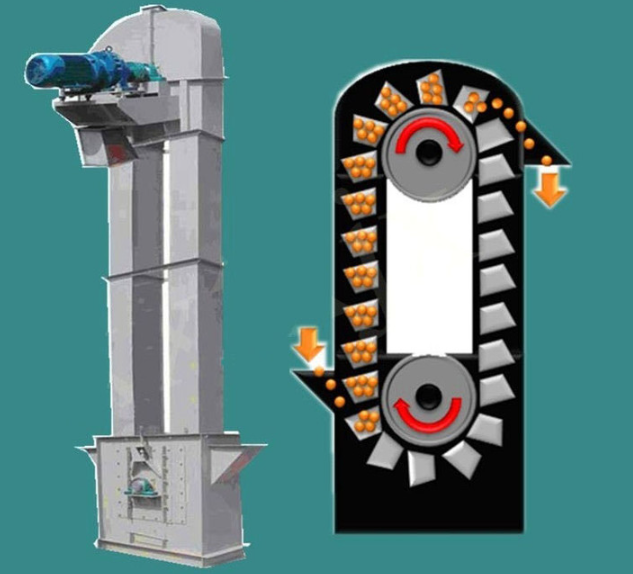

V. Bucket elevator + feeding valve combination

Use the traction chain or tape around the head and bottom of the elevator to drive the hopper installed on it to make a circular motion. After the hopper is loaded at the bottom, it is lifted to the top, and then the material is discharged to complete the feeding process.

Scope of application: Clinker lifting and accurate unloading to loading equipment

Structural features: The upper part is equipped with a slide pipe and an electric flow control valve to control the unloading speed; connected to the hopper to achieve centralized control of feeding.

What can the hopper feeder range for clinker loading be used for?

The hopper feeder range for clinker loading is widely used in bulk material handling systems in cement, building materials, metallurgy and other industries, and mainly undertakes the quantitative feeding and transportation tasks of cement clinker. Its typical application scenarios include the transfer of clinker between the sintering system and the storage system in the cement production line, the quantitative feeding of clinker from the grate cooler outlet to the belt conveyor, bucket elevator or loading system, and the buffering and steady flow operation before bagging or bulk loading. According to the different material particle size, temperature and process requirements, plate feeders can be used to convey high-temperature block clinker, or spiral, vibration and other feeding equipment can be used to achieve sealed or continuous feeding to ensure that the clinker is processed or shipped under efficient and stable conditions.

In the process of clinker loading, the selection of hopper feeding equipment needs to comprehensively consider the material characteristics (particle size, temperature, viscosity, etc.), the process (transportation, loading, warehousing, etc.) and the control accuracy requirements. You can choose the hopper feeder range for clinker loading that best suits the specific clinker loading requirements. If you need a more complete equipment comparison or specific model recommendation (such as for a certain packaging or loading system), you can continue to provide detailed requirements, and we can help you further analyze and customize the equipment.