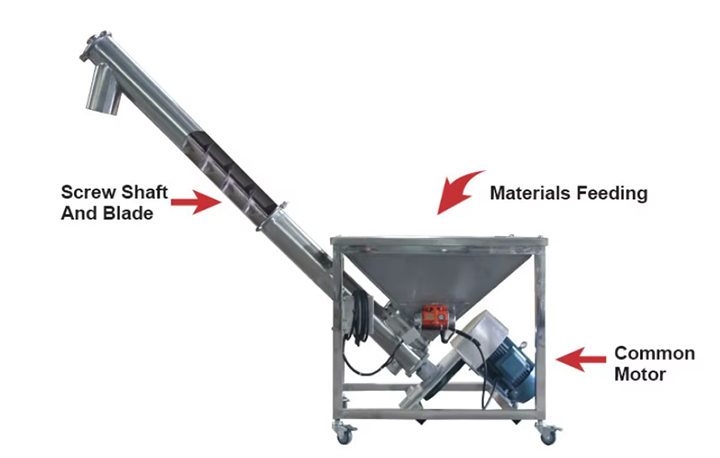

Hopper Vertical Stainless Steel Screw Conveyor

Tuesday January-06 2026 16:27:17

Hopper Vertical Stainless Steel Screw Conveyor uses a continuously rotating screw to transport material from a hopper through a stainless steel pipe from bottom to top to a designated location. The conveying capacity ranges from 1 to 30 m³/h, with screw diameters of 150mm, 200mm, 250mm, 300mm, and 400mm; a larger screw diameter results in a larger conveying capacity. The equipment is made of stainless steel, ensuring material cleanliness. The conveyor's inclination angle ranges from 0° to 45°, achieving a lifting height of 1-6m.

Hopper Vertical Stainless Steel Screw Conveyor Working Principle

Powered by a motor, material is conveyed from the hopper at the bottom through the pipe. The rotating screw blades spin at high speed within the enclosed pipe, generating centrifugal force that pushes the material against the pipe wall, creating a pressure difference. Under the combined action of the continuous pushing of the screw blades and the friction of the pipe wall, the material is forcibly lifted upwards along the screw track, achieving conveying from bottom to top. Finally, the material is discharged at the top outlet by gravity.

Why is a Hopper Vertical Stainless Steel Screw Conveyor needed?

The Hopper Vertical Stainless Steel Screw Conveyor is chosen as the material conveying equipment because it can transport materials at different inclination angles. This not only saves factory floor space but is also suitable for applications requiring the transport of materials from lower to higher levels. The conveyor is made of stainless steel, with a smooth surface that does not easily adhere to materials, preventing corrosion from acidic or alkaline materials. Stainless steel also has good wear resistance, allowing for long-term use. The conveyor's hopper acts as a receiving container, storing materials from upstream equipment, ensuring a uniform and stable material flow at the screw conveyor inlet, preventing material shortages or overloads. The screw blades propel materials in a relatively gentle manner, resulting in a low breakage rate for fragile particles. Furthermore, the conveying process takes place in a closed pipe, preventing material spillage and exposure to air and moisture.

Hopper Vertical Stainless Steel Screw Conveyor Specifications

| Parameter | Typical Value |

| Conveying Capacity | 500 – 3000 kg/h |

| Lifting Height | 1.5 – 6.0 m |

| Material Form | Powder / Granule |

| Bulk Density | 0.3 – 1.5 t/m³ |

| Moisture Content | ≤10% |

| Material Temperature | ≤80°C |

| Screw Diameter | Φ100 / Φ160 / Φ200 mm |

| Rotational Speed | 30 – 120 rpm (Frequency Conversion) |

| Material Contact Material | SUS304 (Optional 316L) |

| Surface Treatment | Polishing (Food Grade) |

| Hopper Capacity | 50 – 200 L |

| Motor Power | 1.1 – 4.0 kW |

| Driving Mode | Reduction Motor |

| Control Mode | Frequency Conversion Control |

| Power Supply | 380V / 50Hz / 3P |

| Installation Method | Fixed Type (Base) |

| Cleaning & Maintenance | Detachable Screw |

| Industry | Food / Chemical / Plastic |

Hopper vertical stainless steel screw conveyor for sale

The price range for the Hopper Vertical Stainless Steel Screw Conveyor is approximately $1850 to $8200. The LS-160 model, priced around $1850-$2300, is equipped with a 0.15 cubic meter hopper, a conveying capacity of up to 5 cubic meters per hour, a standard conveying height of 4-6 meters, and a 2.2 kW motor. The LS-200 model, priced around $2600-$3200, has a 0.25 cubic meter hopper, a conveying capacity of 8 cubic meters per hour, a conveying height of 6-8 meters, and a 3.7 kW motor.

Hopper Vertical Stainless Steel Screw Conveyor Applications

The Hopper Vertical Stainless Steel Screw Conveyor can convey materials such as flour, grains, feed, cement, fly ash, mineral powder, plastic granules, resin, sugar, salt, and additives. These materials originate from industries such as construction, food, chemicals, pharmaceuticals, feed, and plastics.

Hopper Vertical Stainless Steel Screw Conveyor Display

The Hopper Vertical Stainless Steel Screw Conveyor, as a conveying device, can be used in conjunction with cleanroom feeding stations, vibrating screens, mixers, packaging machines, and other equipment. When selecting a hopper, you can contact the manufacturer, Dahan Machinery, who can provide suitable models based on your material conveying needs to meet the required conveying capacity or integration requirements with other equipment.