How to choose a feed pellet belt conveyor?

Thursday May-22 2025 18:05:50

What is a feed pellet belt conveyor

Feed pellet belt conveyor is a continuous conveying equipment dedicated to conveying granular feed materials. It is mainly used in farms, feed mills, and other places. Feed pellets have the characteristics of uniform particle size, small size and brittle texture. They are easily squeezed, broken or generate dust during transportation. Therefore, this type of conveyor usually uses a flat belt or patterned belt with a compact structure and smooth operation to prevent materials from slipping and damage.

Applicable materials for feed pellet belt conveyors

Feed pellet belt conveyors are suitable for conveying a variety of granular or small-block feed materials. Common applicable materials include:

Compound feed pellets: finished pellets such as pig feed, chicken feed, duck feed, fish feed, etc. processed by a pelletizer;

Premix pellets: uniform composition, small particles, suitable for medium and short distance transportation;

Expanded feed pellets: light and fragile, suitable for smooth transportation;

Additive pellets: such as nutritional additives, trace element mixed pellets, etc., require anti-pollution transportation;

Grain raw materials: such as corn crushed, wheat grains, sorghum grains, soybean meal pellets and other feed raw materials;

Other small-block or granular materials: such as grass pellets, straw pellets, cottonseed hull pellets and other pressed feeds.

In general, this conveyor is suitable for non-sticky feed materials with a particle size between 5mm and 20mm, good fluidity, and certain protection requirements during the conveying process.

Feed pellet production: Which type of conveyor should be used?

In feed pellet production, the selection of conveyors needs to comprehensively consider factors such as particle characteristics (such as particle size, hardness, humidity), conveying distance, height, production capacity and environmental protection requirements.

1. Belt conveyor

Low-speed operation with anti-slip belt design is suitable for fragile pellet feeds with a particle size of 2-12mm (such as livestock and poultry feed, aquatic expanded feed), which can reduce the crushing rate. When conveying horizontally or at a small inclination (≤15°), the production capacity is high (up to 50-200 tons/hour), which is suitable for medium and long-distance horizontal transmission in the production line.

Applicable scenarios: horizontal or slightly inclined conveying of dry pellets (moisture content <15%).

2. Scraper conveyor

Can be conveyed vertically, inclined (≤45°) or horizontally, suitable for large conveying volume (especially suitable for large particles or mixed materials, such as pellets containing crushed materials).

Applicable scenarios: vertical lifting of pellet feed (such as from the ground to the second-floor silo), and transportation of wet pellets (water content ≤ 20%).

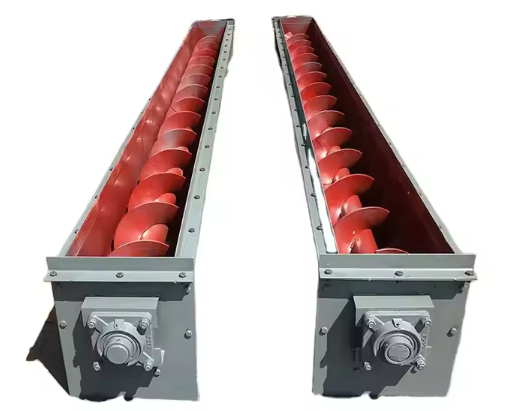

3. Screw conveyor

It occupies a small area and is suitable for vertical or horizontal transportation in narrow spaces (such as unloading at the bottom of the silo). The fully enclosed pipeline design can prevent pellet leakage and dust spillage.

Applicable scenarios: short-distance transportation (<10 meters) of small particles (particle size ≤ 6mm) or powder mixtures, such as mixed transportation of additives and pellets, and trace ingredient links.

4. Bucket elevator

Vertical lifting is achieved through the hopper with material (height can reach more than 20 meters), which is suitable for high-altitude transportation of pellet feed. The low-speed operation of the hopper is combined with the slow feeding design at the bottom, which has little damage to the pellets and is suitable for fragile pellets such as aquatic feed and pet food.

Applicable scenarios: vertical lifting of a single pellet, especially suitable for production lines with large production capacity and high-altitude warehouse layout.

Selection suggestions

Prefer belt conveyor: If the horizontal conveying of dry and fragile particles is the main purpose (such as long-distance transportation of finished particles), belt conveyor is the first choice for cost-effectiveness, taking into account both efficiency and particle integrity.

Wet particles or vertical lifting: If you need to convey freshly granulated hot and wet particles or vertically lift particles, you can choose scraper conveyor or bucket elevator. The former is suitable for large inclination angles and humid environments, and the latter is suitable for high-altitude vertical transportation.

Small space or mixed materials: If the production line space is narrow or mixed particles containing powder need to be conveyed, the screw conveyor can be used as a short-distance supplement, but the hardness and humidity of the particles need to be controlled.

Combination use: In complex production lines, a variety of conveyors (such as "belt conveyor + bucket elevator" combination) can be used to achieve horizontal + vertical efficient transportation, while reducing the load of a single device.

Application of feed pellet belt conveyor