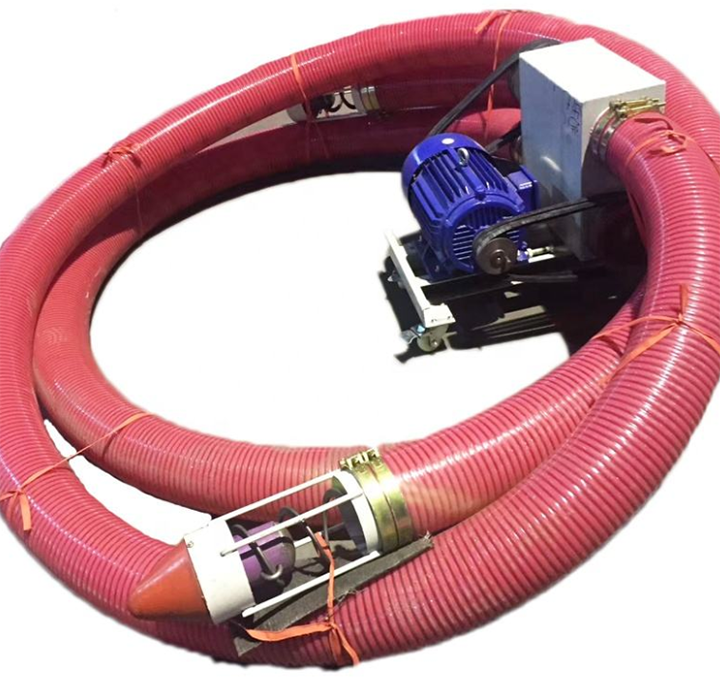

Mobile Hose Screw Conveyor

Monday December-22 2025 18:08:43

The Mobile Hose Screw Conveyor is a material conveying device integrating a screw conveyor, flexible hose, and movable structure. Driven by a motor, rotating screw blades push material within a closed hose, enabling horizontal, inclined, or vertical conveying. The conveying capacity typically ranges from 1 to 30 tons per hour, adjustable depending on the screw diameter and rotation speed. Single-unit conveying distances are generally 3–12 meters, with vertical lifting heights reaching 2–6 meters. The greater the inclination angle, the higher the motor power required. Applicable materials include powders, granules, and small lumps, with a suitable particle size range typically from 0.1 to 20 mm.

Mobile Hose Screw Conveyor Components

The Mobile Hose Screw Conveyor is mounted on a frame with casters or a mobile base, allowing it to be towed by vehicle or manually and moved between different work locations. The power system, transmission device, and support frame are integrated into the chassis. Flexible conveyor hoses are typically made of wear-resistant, tear-resistant reinforced rubber or special plastic composite materials. Their flexibility allows the conveying path to bend freely within a certain range and bypass obstacles, and the conveying distance and outlet position can be adjusted by extending or changing the hose length. Inside the hose is a shaft equipped with continuously spiral blades, driven by a motor or other power system to rotate the screw and continuously propel the material forward.

Advantages of Mobile Hose Screw Conveyor

Mobile Hose Screw Conveyors require no fixed installation and can be quickly deployed to various locations such as trucks, warehouses, docks, or production workshops, solving the problem of limited operating areas for stationary conveyors. The equipment is multi-functional and can be reused in different situations, improving equipment utilization and reducing installation costs. The flexible hose allows for adjustment in horizontal, inclined, and vertical directions, easily reaching deep into truck beds, bypassing equipment or building corners, and adapting to complex spaces. After operation, the hose can be retracted or coiled for convenient storage and transportation while reducing space occupation. The spiral conveying method provides good sealing, preventing dust spillage and protecting the surrounding environment.

How to Choose the Right Mobile Hose Screw Conveyor Model?

When selecting a mobile hoose screw conveyor model, consider the material characteristics, required conveying capacity, and conveying path. Below are three different models: lightweight, general-purpose, and heavy-duty.

Model LH-100E is electrically driven, with a power output of approximately 5.5kW and a conveying capacity of 10-15 m³/h. It comes with an 8-meter food-grade PVC hose. Lightweight, mobile, and affordable, it is suitable for intermittent loading and unloading operations in small farms or warehouses.

Model MH-200D is equipped with a diesel engine, with a power output of 15kW and a conveying capacity of 25-30 m³/h. It comes with a 10-meter abrasion-resistant rubber hose, which can be extended to 15 meters. Powerful and capable of handling various bulk materials such as feed and fertilizer, it is suitable for medium-sized processing plants and outdoor applications without a fixed power source.

The Model HD-300DT uses a high-horsepower diesel engine with a conveying capacity of 40-50 m³/h, equipped with a heavy-duty chassis and a 12-15 meter double-layer steel wire reinforced abrasion-resistant hose. Optional features include a hydraulic lifting system and dust collection interface. It is suitable for large-scale transfer of powdery and granular materials in industries such as ports and building materials, offering high durability.

Mobile Hose Screw Conveyor Price

The price of a Mobile Hose Screw Conveyor varies depending on factors such as conveying capacity, power type, hose material, and length. A basic small electric model with a conveying capacity of approximately 10-15 m³/h and a hose length of 6-8 meters typically starts at around $3,000 to $7,000. Medium-sized diesel-powered models are suitable for outdoor or unreliable power supply conditions, with a conveying capacity of 20-30 m³/h. Prices with longer or more abrasion-resistant hoses can range from $7,500 to $10,000. For large, high-capacity customized equipment using special materials or explosion-proof motors, the price may exceed $15,000.

What are the suitable applications for the Mobile Hose Screw Conveyor?

The Mobile Hose Screw Conveyor is suitable for various scenarios, including transporting grain from grain trucks to warehouses or processing equipment; handling grain silos for unloading and cleaning; feeding feed into mixers; loading and bagging finished feed; transporting granular or powdered raw materials from stockpiles to production lines; unloading materials from containers; loading and unloading bulk materials from small vessels; and rapid transfer of bulk cargo in logistics centers.

The Mobile Hose Screw Conveyor successfully fills the gap between stationary large-scale conveying equipment and completely manual handling, providing an economical solution for small- to medium-batch, multi-location, short-distance bulk material transport tasks. It demonstrates advantages in multiple industries and scenarios. Through scientific selection and reasonable application, it can not only improve material transport efficiency but also reduce production costs, making it a reliable choice for bulk material transport systems.