Model 400 Auger Conveyor

Saturday September-13 2025 15:18:36

What is the Model 400 Auger Conveyor?

Model 400 Auger Conveyor uses the rotation of spiral blades to propel materials along the conveyor pipe, thereby conveying materials. The conveying capacity of the equipment is related to the rotational speed. For example, at a rotational speed of 71 rpm, the conveying capacity is 62 cubic meters per hour. The lower the rotational speed, the lower the conveying volume. It can convey powdered, granular, or small-block materials, such as cement, grain, and coal. Common materials include ordinary carbon steel and stainless steel. The equipment is available in inclined, vertical, and U-shaped configurations, enabling horizontal, inclined, and vertical conveying of materials.

Model 400 Auger Conveyor Materials

The materials used in the Model 400 Auger Conveyor vary depending on the structure. U-shaped screw conveyors primarily convey materials horizontally, while inclined and vertical screw conveyors can convey materials at an angle or vertically.

The U-shaped Auger Conveyor consists of a U-shaped trough, a hollow shaft with spiral blades, drive and end bearing housings, hanger bearings, a motor reducer, and an inlet and outlet. Rotating blades propel materials along the trough, either horizontally or at an angle, for conveyance.

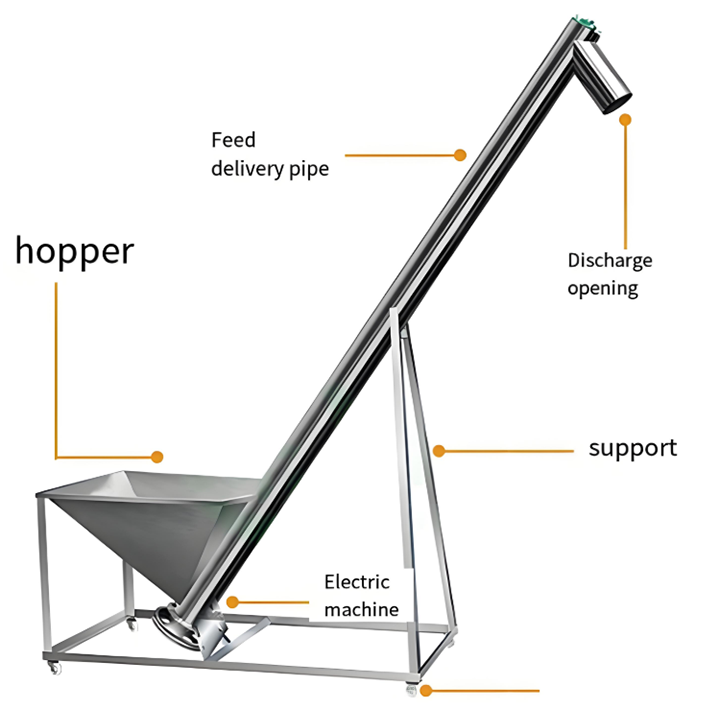

The core components of both the inclined and vertical Auger Conveyors are the same, consisting of a motor-reducer-driven screw shaft, housing, bearing assembly, and inlet and outlet ports, ensuring stable material conveyance at various angles.

Model 400 Auger Conveyor Parameters

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 |

Model 400 Auger Conveyor Types

The Model 400 Auger Conveyor is divided into three types based on the direction of material conveying: the inclined type saves space and is suitable for conveying at medium and high angles; the vertical type takes up little space and is used for lifting at large angles; and the U-type type facilitates cleaning and is suitable for applications prone to residue.

The inclined Model 400 Auger Conveyor is suitable for granular and small-block materials such as grain, plastic pellets, coal slag, and ore fragments. It can handle moderately moist, non-sticky materials and effectively prevents material from slipping or sticking to the auger due to the inclined angle. When the angle is ≤30°, the conveying capacity is approximately 20-45 m³/h. As the angle increases, the conveying capacity gradually decreases. It enables material transfer between different heights, significantly saving horizontal space and is ideal for vertically connecting small and medium-sized production lines.

Vertical Model 400 Auger Conveyor: Suitable for dry powders (such as flour and cement) and fine granular materials. High material flowability and agglomeration are required to prevent clogging of the spiral channel. Stable conveying capacity ranges from 15-35 m³/h. Its vertical conveying height can reach 3-8 meters, offering extremely high space utilization. It can be equipped with anti-blocking devices and a discharge port cleaning mechanism, making it suitable for applications requiring vertical material lifting in tight spaces, such as silo refilling.

U-Shaped Model 400 Auger Conveyor: Suitable for conveying granular, powdered, and small-block materials. It can also handle slightly sticky materials (such as wet sand and distiller's grains). The U-shaped trough design facilitates the cleaning of residual material. When conveying horizontally, the conveying capacity can reach 30-50 m³/h, over distances up to 20 m, and conveying efficiency is minimally affected by material uniformity. It primarily transports horizontally or at low angles. The open design of the trough allows for easy inspection and monitoring of material conditions, making the equipment easy to maintain and suitable for industries such as the food and chemical industries, which require frequent equipment cleaning.

Model 400 Auger Conveyor Applications

In the construction industry, the Model 400 Auger Conveyor can be used in concrete mixing plants to transport powdered materials such as cement and fly ash, and can also transport granular materials such as sand and gravel on construction sites. In the food industry, it can transport raw materials such as grain and flour, as well as finished products and packaging materials in candy and vegetable production lines. In the chemical and pharmaceutical fields, it can transport fertilizers and powdered medicines. Furthermore, it can reliably perform conveying operations in agricultural grain storage, mining ore transfer, and waste disposal.

The Model 400 Auger Conveyor is an ideal conveying device for conveying small particles, powders, and pastes. It can be configured as either horizontal or inclined, depending on the material being conveyed. The Model 400 Auger Conveyor is available with a diameter of 400 mm. For other models, please contact us. We can customize them based on factors such as length and functionality.