RLS100 Flexible Screw Conveyors

Monday May-19 2025 17:36:09

What is RLS100 Flexible Screw Conveyor?

RLS100 flexible screw conveyor is a light mechanical equipment used for the transportation of powder and granular materials. It is a common model in the flexible screw conveyor series. The device pushes the material forward in the flexible pipe through the rotation of the internal spiral spring (helix). It is suitable for bulk material transportation in various industries and scenarios. Its "flexible" feature is that the conveying pipe can be bent, so that it can adapt to complex conveying paths and space restrictions.In "RLS100":

"RLS" is usually the code name for equipment such as "flexible screw conveyor", which comes from its English name; "100" generally represents the diameter of the conveying pipe is 100 mm, that is, φ100mm.

Applicable materials for RLS100 Flexible Screw Conveyors

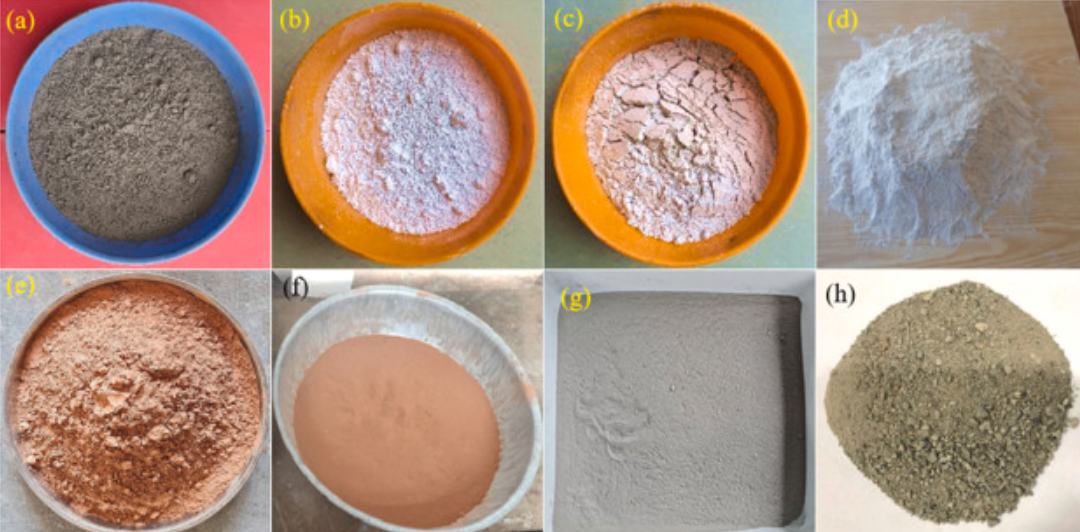

RLS100 flexible screw conveyor is suitable for conveying the following materials:

Dry powder: such as flour, milk powder, starch, calcium carbonate, aluminum oxide, flour, additives, etc.;

Small particles: such as coffee beans, feed particles, plastic particles, grains;

Lightweight materials: such as foam particles, wood chips;

Scenarios that have requirements for the conveying path and need to bypass obstacles.

Working Principle of RLS100 Flexible Screw Conveyors

The spiral body adopts a flexible spiral body, which is usually made of stainless steel wire or other flexible metal materials. It has good flexibility and strength, can adapt to different bending angles and paths during the conveying process, and ensure the stable conveying of materials. The conveying pipe is generally a flexible hose, such as a rubber hose or a plastic hose, with an inner diameter of 100mm. This hose can not only be bent, but also effectively reduce the leakage of materials during the conveying process. The drive device is equipped with a motor with suitable power, such as a single drive motor, the power is generally 3kW, and the spiral body is driven to rotate through transmission parts such as a reducer to provide power for material conveying.

The RLS100 flexible screw conveyor uses the rotation of the spiral to push the material. When the motor drives the flexible spiral body to rotate in the conveying pipe, the material will be pushed by the blades of the spiral body and move forward along the direction of the conveying pipe, thereby realizing the conveying of the material. Due to the flexibility of the spiral body and the conveying pipe, the conveyor can be flexibly arranged in different spatial positions to adapt to various complex conveying routes.

What are the advantages of RLS100 Flexible Screw Conveyors?

Flexible spiral blade structure reduces the risk of material blockage: some powders or wet particles are prone to block pipes and arches during transportation, resulting in interruption of transportation. RLS100 adopts an elastic spiral structure, and the spiral blades have a certain degree of self-adjustment, which can adapt to slight changes in material accumulation. Some models are equipped with a variable pitch spiral design, which can effectively prevent material accumulation at the end of the conveying. Continuous rotation during the conveying process also has a certain "self-cleaning" effect, reducing the probability of material agglomeration.

Reduce the risk of material moisture absorption and deterioration: some materials such as powdered sugar, milk powder, flour, etc. are prone to moisture absorption and agglomeration, affecting the conveying effect. The RLS100 flexible screw conveyor is fully enclosed during the conveying process to reduce the possibility of moisture entering the air. Stainless steel or anti-stick coating conveying pipes can be selected according to needs to reduce the problem of material agglomeration and wall adhesion.

Ease the conveying process and protect the integrity of material particles: some particles are easily broken or worn during rigid spiral or pneumatic conveying, affecting material performance. The flexible spiral conveying method is relatively gentle and does not rely on high-speed impact or pneumatic traction, so the risk of particle breakage is relatively small. The conveying speed is adjustable. According to the material properties, the appropriate running speed is selected to control the conveying rhythm.

Flexible path arrangement to adapt to complex spatial structure: The production site is small or there are obstacles between equipment, and traditional rigid conveying equipment is difficult to deploy. The RLS100 conveying pipe is made of flexible material, and the spiral blade can also be bent, supporting multi-angle bending (≤90°), which can be arranged around obstacles and space return. It can combine horizontal, inclined, vertical and other conveying path methods without changing the existing process layout.

How far can the conveying distance of the RLS100 flexible screw conveyor reach?

The conveying distance of the RLS100 flexible screw conveyor will be affected by many factors. Under normal circumstances, the horizontal conveying distance of a single conveyor can reach about 10 meters, and the vertical conveying height can reach about 6 meters.

If multiple RLS100 flexible screw conveyors are used in series, longer distance conveying can be achieved. In addition, the conveying distance is also related to factors such as the characteristics of the material (such as particle size, humidity, fluidity, etc.), the speed of the spiral body, the inner diameter and material of the conveying pipe. In practical applications, it is necessary to determine the optimal conveying distance and conveying parameters through calculation or experiment according to the specific materials and working conditions.

Application of RLS100 Flexible Screw Conveyors

Grain conveying: This is one of the main applications of RLS100. It can efficiently and gently convey various grains, such as wheat, corn, rice, soybeans, sorghum, etc. It is widely used in the feeding and unloading of granaries, conveying grains from the unloading point to the granary, or from the granary to the processing equipment or loading point; material transfer within the farm, conveying grains between different agricultural machinery or processing equipment; feed processing plants, conveying grain raw materials to feed production lines.

Feed processing industry: RLS100 flexible screw conveyors can be used for raw material conveying. In addition to grains, they can also convey feed raw materials such as soybean meal, bran, and corn flour; finished product conveying is to convey the mixed feed to the packaging machine or other equipment.

Food industry: It can convey powdered food raw materials such as flour, starch, powdered sugar, milk powder, etc.; convey granular materials such as coffee beans, cocoa beans, cereal foods, etc.; materials that need to be gently conveyed to avoid material breakage or deterioration during the conveying process.

Chemical and building materials industry: conveying powdered and granular chemical raw materials, such as plastic particles, powdered additives, etc. The conveying of materials with high sealing requirements can reduce dust leakage and protect the environment and the health of operators. When conveying powdered materials such as cement, fly ash, and lime, the conveyor transfers and batches materials during the production process. Conveying mortar, dry mixes, etc. is suitable for production lines with a high degree of automation.

In short, the RLS100 flexible screw conveyor effectively solves the problems of limited conveying paths, material residues, easy breakage, dust leakage, low efficiency and difficult maintenance encountered in the traditional material conveying process through its flexible structure, closed conveying, gentle conveying and possible special designs, providing users with a flexible, efficient and economical material conveying solution, especially suitable for the conveying of bulk materials such as grains.