SS Auger Screw Conveyor

Thursday May-22 2025 11:53:58

What is SS Auger Screw Conveyor?

SS auger screw conveyor is a stainless steel screw conveying equipment widely used in food, pharmaceutical, chemical and other industries. Its main features include corrosion resistance, high temperature resistance, and easy cleaning. It is made of 304L or 316L stainless steel to ensure that the material is pollution-free and meets high hygiene standards. The equipment pushes powdered, granular or block materials along the pipe or trough through rotating spiral blades. The conveying capacity can reach 2.2-458m³/h, and the screw diameter is 100-1250mm. SS screw conveyors are divided into tubular, trough and shaftless types. The tubular type has good sealing and is suitable for powder materials; the trough type is suitable for horizontal or small angles. Conveying; shaftless handling of sticky or irregular materials.

Applicable materials for SS auger screw conveyors

SS auger screw conveyors are suitable for conveying various types of powdered materials, especially for working conditions with high requirements for material cleanliness or conveying environment. Since the whole machine is made of stainless steel, the surface is smooth and not easy to stick to the material, which can effectively avoid material residue and cross contamination, and is suitable for food-grade or pharmaceutical-grade powder conveying scenarios. Commonly applicable powders include:

Food powders such as flour, milk powder, starch, and seasoning powder; pharmaceutical raw materials such as medicinal powder, vitamin powder, and granular powder

Chemical raw materials such as lime powder, talcum powder, calcium carbonate powder, and alumina powder Powder; industrial fine powders such as washing powder, additives, plastic additives, metal powder, etc.

Classification of SS auger screw conveyors

SS auger screw conveyors can be divided into the following categories according to the different structural forms and screw shaft configurations:

1. Classification by shell structure

Trough screw conveyor (U-type): The conveyor is U-shaped or trough-shaped, with a cover or open design, which is easy to observe and maintain, and is suitable for horizontal or small-angle conveying. It is suitable for conveying powder or small particles that are not very sticky and not easy to raise dust. It is often used for conveying general industrial powders and building materials.

Tube screw conveyor (O-type): The conveyor shell is closed The circular tube structure, the spiral blades rotate in the tube to transport materials, with good sealing, suitable for conveying powder materials that are easy to generate dust, easy to pollute or have high requirements for the conveying environment, such as food, medicine or fine chemical products. Commonly used in vertical or inclined arrangements.

2. Classification by spiral shaft structure

Shafted screw conveyor: The spiral blades are fixed on the central shaft, with a stable structure, suitable for powdered, granular and dry materials with good fluidity, such as cement powder, coal powder, etc. A hanging bearing needs to be set in the middle to support long-distance transportation.

Shaftless screw conveyor: There is no central shaft, the spiral blades are rolled from thick plates, with high overall rigidity, suitable for It is suitable for conveying high-humidity, high-viscosity, and easily entangled materials, such as sludge, kitchen waste, etc. It is easy to clean and maintain and is suitable for special working conditions.

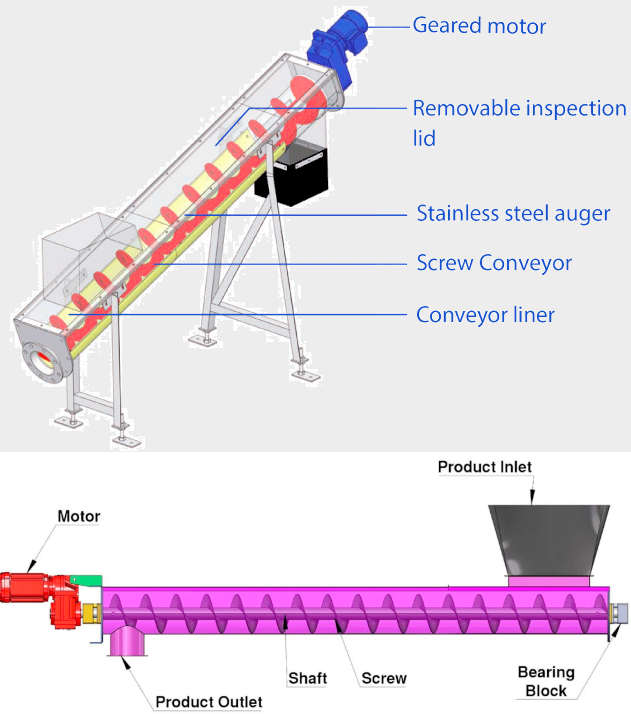

Structure and working principle of SS auger screw conveyor

SS screw conveyor (stainless steel screw conveyor) is mainly composed of core components such as screw shaft assembly (spiral blades, center), shell, bearing and drive device, feed port/discharge port, etc., and each component cooperates to realize the material conveying function.

The motor drives the screw shaft to rotate, and the spiral blade rotates accordingly. The friction thrust between the blade and the material is used to push the material along the axial direction of the casing. The material moves forward in the trough or tube body with the spiral movement. In horizontal conveying, the material friction is overcome mainly by the thrust of the spiral blades; in inclined conveying, the material needs to overcome the gravity force in addition to the spiral thrust, so the inclination angle is generally not more than 20° to avoid material return or blockage.

The material does not roll or mix during the conveying process, which is suitable for materials with good fluidity such as powders and fine particles. For highly viscous or easily entangled materials, it is recommended to use a shaftless structure to prevent blockage.

Application of SS auger screw conveyor

SS screw conveyor is mainly used in food, medicine, chemical industry, environmental protection, etc. In industries with requirements for material cleanliness or corrosivity, it is used to transport various types of powders, granules and small pieces of materials. In the food industry, it is often used to transport flour, sugar powder, milk powder, seasoning powder, etc. In the pharmaceutical industry, it can be used to transport high-cleanliness materials such as drug powder and additives to ensure a safe production environment; in the chemical industry, it is suitable for transporting corrosive powders such as calcium carbonate, lime powder, titanium dioxide, etc. SS auger screw conveyor has strong corrosion resistance; in the environmental protection industry, it is used to process sludge, waste, filter residue and other materials with a certain degree of humidity and viscosity. In particular, the shaftless structure is more suitable for transporting water-containing or easily entangled materials. The equipment can be used with silos, mixers, etc. The combination of the screw conveyor and the packaging machine forms an automated conveying system that can meet various process requirements and is suitable for various layout modes such as horizontal and inclined, with strong flexibility.

SS Auger Screw Conveyor has become the preferred equipment for material transportation in many industries due to its corrosion resistance, good sealing and strong adaptability. The selection should be combined with the material characteristics and process requirements, and regular maintenance should be carried out to ensure stable operation. If a specific model or customized solution is required, it is recommended to contact the manufacturer of Dahan Machinery for technical support. The company supports non-standard customization, and you can also choose materials for free trial in our factory. "Summarize briefly and summarize it into a paragraph