Sand Grain Suction Machine

Friday May-23 2025 16:45:15

Sand has the characteristics of small particle size, light weight, good fluidity but easy to raise dust, and is used in large quantities in industries such as construction and casting. In order to efficiently convey sand, a sand grain suction machine came into being. Its working principle is to use a fan to generate negative pressure, form a mixed flow of sand and air through a pipe, and quickly suck sand from one place to another, effectively avoiding the inefficiency and dust pollution of manual handling.

Working principle of sand grain suction machine

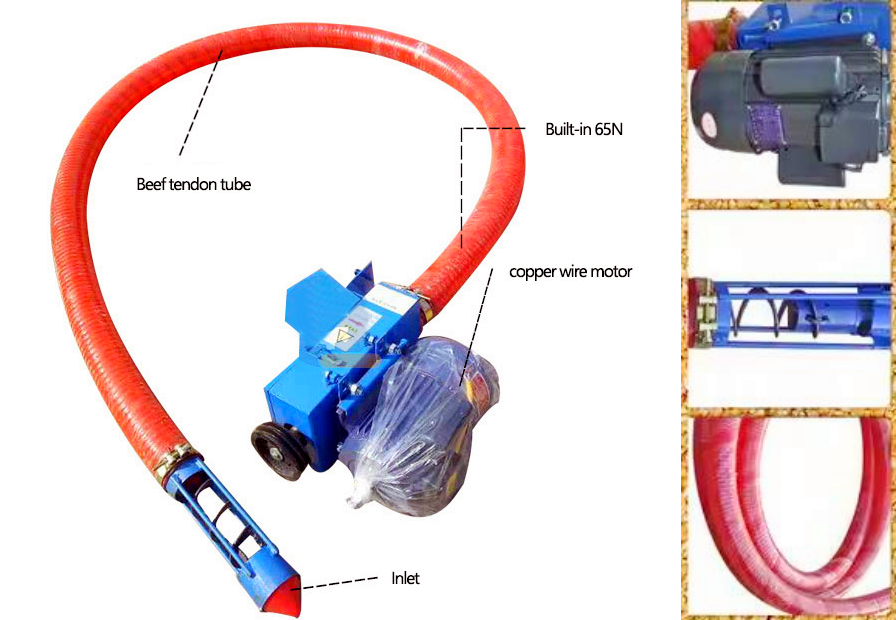

The sand grain suction machine uses a vacuum pump or fan to generate negative pressure to form a high-speed airflow, and sucks sand from the silo, ground or container into the conveying pipeline through the suction port. Sand (usually 0.1-5mm in diameter) has good fluidity but high hardness, and is transported to the target location, such as a silo or processing equipment, along the wear-resistant pipeline driven by the airflow.

The system usually includes a suction nozzle, a conveying pipeline, a separator and a dust removal device. The separator separates the sand from the air by gravity or the cyclone principle, and the sand falls into the collection container. The gas is discharged after dust removal and filtration. To avoid clogging with high-humidity sand, some equipment is equipped with a vibrating screen or drying device. The conveying efficiency of the suction machine is affected by the mesh size of the sand (20-200 mesh), the bulk density and the airflow velocity. The typical conveying capacity is 300-1000kg/h. Suitable for continuous or intermittent sand delivery.

What are the advantages of the sand grain suction machine?

Solve the problem of sand conductivity: Many carbon sand particles (such as conductive carbon black and graphite) are conductive. During pneumatic conveying, friction between particles and friction with the pipe wall can easily cause static electricity accumulation. Non-metallic parts such as pipes and filter bags that come into contact with materials should be made of conductive or antistatic materials, and the equipment design and manufacturing should meet the corresponding explosion-proof standards.

Solve the problem of large differences in sand density: Different types of carbon sand particles have different densities, from light carbon black to heavy coke, which requires the suction machine to have a wide range of adaptability. Improve the sealing of each connection of the equipment to prevent moisture from entering and affecting the quality of the carbon sand particles. Improve the sealing of each connection of the equipment to prevent moisture from entering and affecting the quality of the carbon sand particles.

Deal with poor fluidity or easy bridging problems: Some carbon sand particles, especially those with uneven particle size or containing a certain amount of humidity, may have bridging in the silo or pipeline, resulting in poor material flow or even complete blockage, affecting continuous production. In some cases, a fluidizing plate can be set at the bottom to allow a small amount of air to pass through the micropores to fluidize the material and increase its fluidity.

The sand particles are highly abrasive: Carbon sand particles (such as graphite, carbon black, coke, etc.) often have high hardness and edges, causing serious wear on equipment parts, shortening equipment life and increasing maintenance costs. The use of a large curvature radius of the gentle elbow design reduces the impact angle and number of materials and elbow walls, reducing wear.

Recommended mesh number for sand grain suction machine

|

Sand type |

Particle size range (mm) |

Corresponding mesh number (approximately) |

Applicable suggestions |

|

Coarse sand |

1.0 - 2.0 |

10 - 18 mesh |

A high-power suction machine is required to prevent particle blockage, suitable for casting, floor sand, etc. |

|

Medium sand |

0.5 - 1.0 |

18 - 35 mesh |

Suitable for general suction machine, smooth conveying, commonly used in building materials, quartz sand, etc. |

|

Fine sand |

0.25 - 0.5 |

35 - 60 mesh |

It is recommended to use equipment with good sealing and dust removal system to avoid dust |

|

Extra fine sand/quartz powder |

0.075 - 0.25 |

60 -200 mesh |

Small particle size is easy to raise dust, and pipeline blockage needs to be prevented |

The mesh number refers to the number of mesh holes per inch on the screen. The larger the value, the finer the particle size.

The selection of suction machine needs to be considered comprehensively in combination with factors such as the dryness of the sand, the conveying distance and the processing volume.

It is not recommended to use standard sand grain suction machines for ultrafine powders with a mesh size of more than 200 (particle size less than 0.075mm). Special powder vacuum conveying equipment can be considered.

What are the applications of sand grain suction machines?

Sand suction machines are widely used in industrial scenarios that require efficient and clean sand conveying, especially in casting, building materials, glass, refractory materials and chemical industries. They have strong practical value. In the foundry workshop, carbon sand, resin sand and other molding sand need to be frequently transported between different workstations, such as sucking sand from the sand storage bin and then transporting it to the sand mixer or molding line. Traditional manual handling is inefficient and dusty. Suction machines can achieve fully automatic closed transportation, reduce labor intensity and keep the workshop clean.

In the building materials industry, such as cement floor construction, mortar mixing and other links, suction machines can quickly transport dry sand to construction points high on the floor, solve the problem of high-altitude feeding and improve construction efficiency. In glass manufacturing, the dust and moisture content of quartz sand must be strictly controlled during the transportation process. The suction machine can quantitatively feed dry sand into the mixture in a closed state to ensure product quality. In the refractory industry, a large amount of granular sand needs to be mixed in proportion and transferred at a high frequency. The suction machine is linked with the batching system to achieve accurate and fast multi-point feeding. In addition, in the packaging process of fine particles such as quartz sand and talcum powder, the material can also be directly transported to the automatic packaging machine through the suction machine to avoid dust pollution and material waste. In general, the sand grain suction machine replaces the traditional handling mode in various sand processing scenarios through efficient and closed conveying methods, improves the level of production automation, and is especially suitable for high-frequency and large-volume sand transfer process.

In summary, the sand grain suction machine is an automated material conveying equipment designed for sand materials (such as quartz sand, corundum, foundry sand, machine-made sand, etc.), which is mainly used to achieve efficient, environmentally friendly and safe transmission of sand, and solve the problems of low efficiency and dust pollution in traditional manual or mechanical conveying.