Slag powder Flexible Screw Conveyor

Thursday January-22 2026 16:12:55

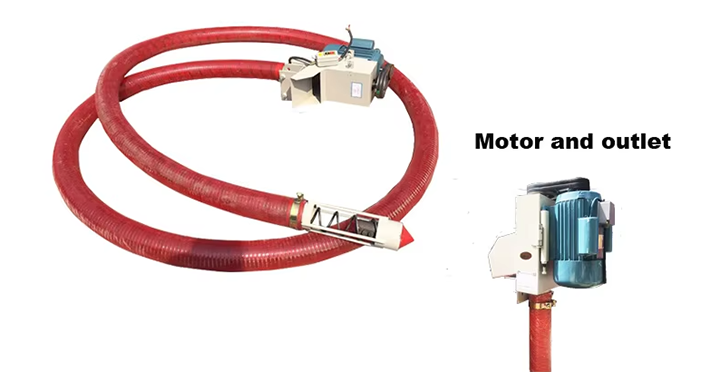

Slag powder Flexible Screw Conveyor uses a continuously rotating flexible screw to transport slag powder to the required location. The conveying capacity ranges from approximately 0.1 to 8 tons per hour. The equipment comes in two types: a flexible screw conveyor made of wear-resistant PVC material and an inclined flexible screw conveyor with a hopper. Both types have slightly flexible conveying pipes. The equipment uses PVC flexible hoses, resulting in low operating noise. The price is approximately $600-$2000.

How does the Slag Powder Flexible Screw Conveyor work?

At a mixing plant or cement plant, slag powder is first discharged from the hopper, or it can be manually poured into the hopper. After the Slag Powder Flexible Screw Conveyor starts, the motor drives the flexible screw inside the hose to rotate. The screw acts like a propeller, pushing the slag powder forward along the closed pipe. During the conveying process, the slag powder is in a completely sealed environment, preventing dust and leakage, and can be conveyed horizontally or at an incline around on-site equipment and pillars. Upon reaching its destination, the slag powder is steadily fed into a weighing scale, mixer, or intermediate silo, achieving continuous and controllable powder conveying.

Advantages of a Slag Powder Flexible Screw Conveyor

Slag powder presents challenges during conveying due to its fine texture, tendency to generate dust, high density, moderate flowability, abrasiveness, and susceptibility to agglomeration when damp. The Slag Powder Flexible Screw Conveyor features a sealed pipeline, preventing slag powder from scattering and impacting the surrounding environment. Furthermore, the sealed pipeline minimizes slag powder loss during transport. The flexible screw continuously breaks up agglomerated slag powder, propelling the less flowable powder forward until it is discharged from the outlet.

Types of Slag Powder Flexible Screw Conveyors

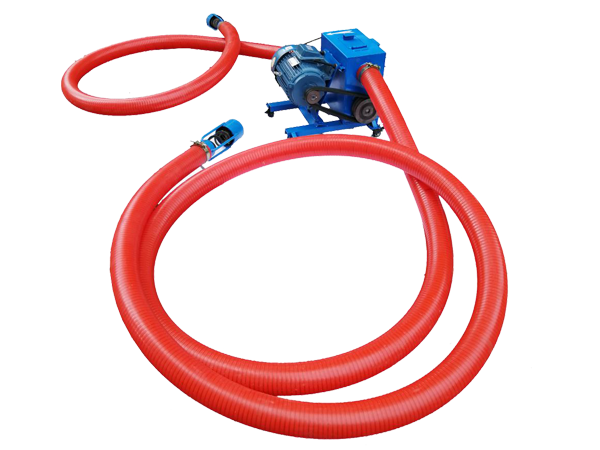

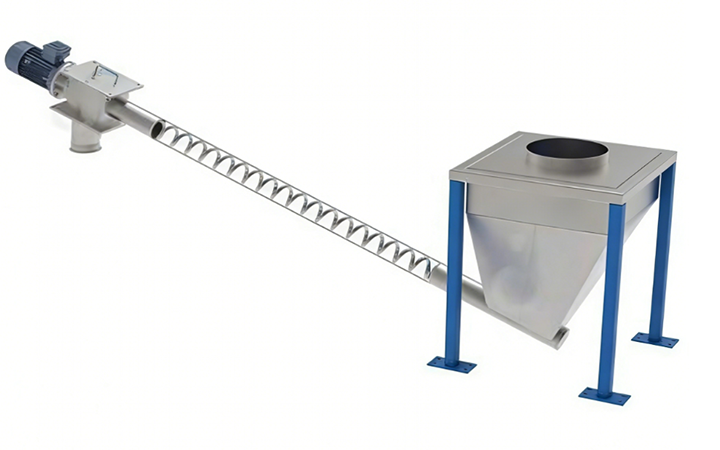

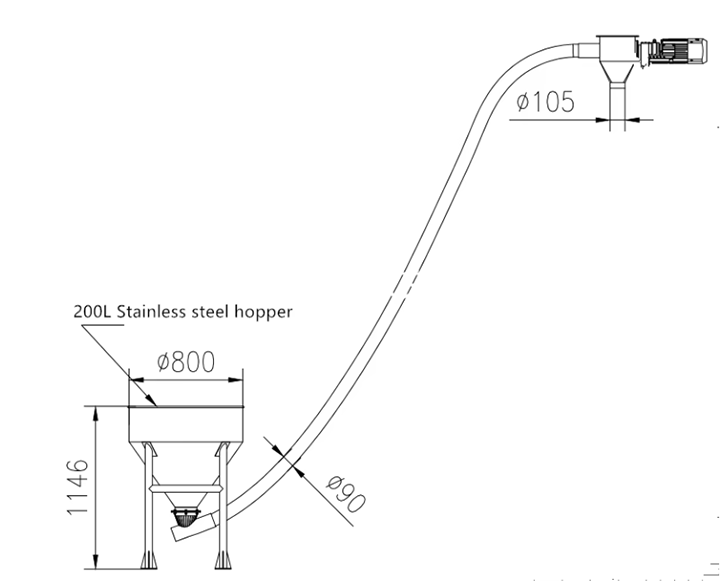

Slag powder flexible screw conveyors are available in two types: wear-resistant PVC flexible screw conveyors and inclined flexible screw conveyors with hoppers. The flexible screw conveyor made of wear-resistant PVC has a flexible pipe that can be bent, allowing it to convey slag powder horizontally, inclined, or vertically. The inclined flexible screw conveyor with a hopper also has a flexible pipe, and this equipment can be linked with upstream and downstream equipment to create a closed slag powder production line. The left image below shows a wear-resistant PVC flexible screw conveyor, and the right image shows an inclined flexible screw conveyor with a hopper.

Slag Powder Flexible Screw Conveyor Parameters

| Parameter Item | Wear-Resistant PVC Flexible Screw Conveyor | Inclined Hopper-Type Flexible Screw Conveyor |

| Conveying Form | Flexible screw + wear-resistant PVC hose | Flexible screw + hopper + inclined conveying |

| Hose Material | Wear-resistant PVC | Wear-resistant PVC / PU |

| Screw Material | Spring steel / high carbon steel | Spring steel / high carbon steel |

| Conveying Direction | Horizontal / inclined / curved | Mainly inclined |

| Conveying Angle | 0-45° | 15-60° |

| Conveying Length | 2-12 m (customizable) | 3-15 m (customizable) |

| Conveying Capacity | 0.5-5 t/h | 1-8 t/h |

| Hopper Configuration | None | 0.2-1.5 m³ |

| Feeding Method | Manual feeding / upstream equipment | Hopper gravity feeding |

| Discharging Method | Direct discharge / flange connection | Flange connection / flexible connection |

| Driving Method | Motor + reducer | Motor + reducer |

| Motor Power | 0.75-3 kW | 1.5-5.5 kW |

| Sealing Performance | Good | Excellent |

| Installation Method | Mobile / fixed | Fixed |

| Maintenance Difficulty | Low | Medium |

| Typical Application | Short distance, flexible arrangement | Continuous feeding, automated production lines |

Slag Powder Flexible Screw Conveyor Price

The price of a slag powder flexible screw conveyor depends on the configuration and length. The wear-resistant PVC flexible hose type has a simple structure and typically costs between $500 and $1,800. The inclined type with a hopper, due to the need for a stainless steel hopper, a powerful motor, and a support frame, typically costs between $1,500 and over $3,000. Factors such as the conveyor length, screw diameter, drive motor power, control system, and materials will affect the price; a customized quote can be provided based on actual working conditions.

Applications of Slag Powder Flexible Screw Conveyors

Wear-resistant PVC Slag powder flexible screw conveyors are suitable for conveying slag powder in confined spaces, with complex paths, and requiring multiple feeding points. Examples include non-linear curved connections within workshops, feeding from storage hoppers to mobile packaging machines, or serving as temporary bypass conveyors where the discharge port needs frequent changes. Inclined Slag powder flexible screw conveyors with hoppers, through the buffering effect of the hopper and the lifting action of the screw, are suitable for situations requiring overcoming gravity to convey slag powder from low to high places or at specific angles. Examples include lifting bulk or bagged slag powder from the ground to high storage hoppers, the top inlet of mixers, or as an automated feeding system at the front end of a production line requiring manual dumping of raw materials and possessing inclined lifting capabilities.

Slag powder, produced during industrial smelting, can be used in various production processes such as concrete admixtures, cement production, and special engineering materials. A flexible screw conveyor for slag powder is an intermediate device that transports slag powder to the production location through a closed, continuous conveying system, thus accelerating material production. When selecting a conveyor, two different types can be chosen based on the slag powder production scenario: a wear-resistant PVC flexible screw conveyor or an inclined flexible screw conveyor with a hopper. Alternatively, customized equipment can be provided based on pipe diameter, length, and other specifications.