Tie the rope to put urea into the hopper of the screw conveyor

Monday September-15 2025 14:03:22

What is Tie the rope to put urea into the hopper of the screw conveyor?

Tie the rope to put urea into the hopper of the screw conveyor . By securing and pulling the rope, the screw conveyor ensures stable speed control, prevents spillage, and accurately feeds urea during transfer to the screw conveyor hopper. This prevents urea loss or clogging of the hopper entrance due to improper handling, reduces operational risks associated with direct human contact with urea, and lays the foundation for subsequent automated conveying.

Urea, a granular fertilizer that is easily hygroscopic and prone to agglomeration, requires special attention to moisture and clogging prevention during storage and transportation. This equipment is typically constructed of carbon steel, stainless steel, or wear-resistant alloys to withstand the corrosive and abrasive properties of urea. Typical models have an hourly conveying capacity of 1 to 10 cubic meters.

Tie the rope to put urea into the hopper of the screw conveyor Advantages

Tie the rope to put urea into the hopper of the screw conveyor offers significant advantages. First, it's cost-effective. Compared to purchasing dedicated automatic loading equipment, the rope-tying method requires no complex mechanical devices, only basic ropes and lifting tools. This reduces equipment investment costs by over 60%. Maintenance is also simple, making it suitable for small and medium-sized fertilizer production or use companies.

Second, it offers operational flexibility. The rope can be adjusted to suit the urea packaging format, such as bagged or bulk. Whether feeding small batches or transporting large quantities, the feed rate can be adjusted by controlling the rope's untying speed. This allows for adaptability to screw conveyor hoppers of varying sizes, solving the problem of limited adaptability for fixed-loading equipment.

Finally, it offers high safety. Rope tying effectively secures the urea, preventing injuries caused by the material slipping during manual handling. It also reduces the time the urea spends in direct contact with air, reducing the likelihood of moisture absorption and agglomeration. This indirectly ensures safe and stable subsequent transportation and storage, and reduces equipment failures caused by material problems.

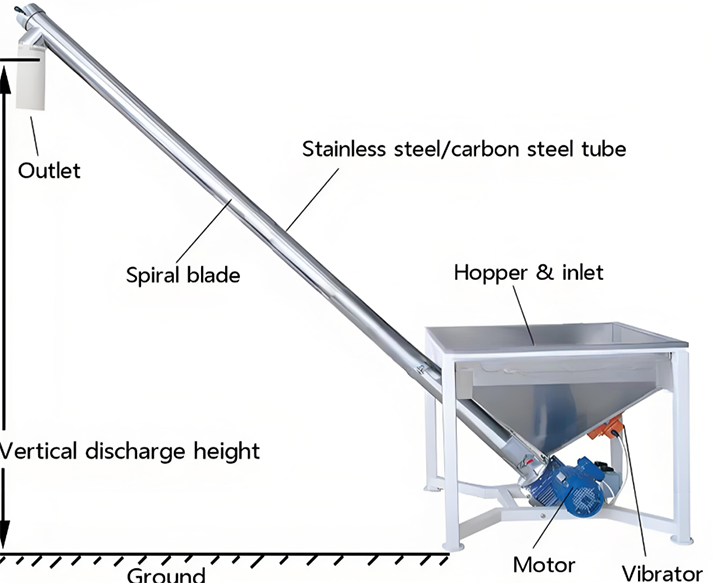

Tie the rope to put urea into the hopper of the screw conveyor structure diagram

Urea Conveying System

In the urea conveying system,Tie the rope to put urea into the hopper of the screw conveyor is a crucial step in connecting raw material handling with automated transportation. By tying the rope to the urea bags and hanging them above the hopper, workers can control the speed and direction of urea delivery, preventing dust and waste. The conveying system typically consists of a hopper, a screw conveyor, a drive unit, and a discharge port. The spiral blades rotate within a sealed pipe, moving the urea forward smoothly while preventing the ingress of foreign matter. The system can also be equipped with a vibration device to prevent blockage caused by urea clumping due to moisture absorption.

Urea Storage System

The stable operation of the urea storage system also depends onTie the rope to put urea into the hopper of the screw conveyor. Urea storage silos are typically located at the end of screw conveyors. Before being transported to the silo via the conveyor, urea must first be temporarily stored and buffered in a hopper. Directly pouring urea into the silo can easily cause lumps and dust to form inside the silo due to impact. However, using a rope to slowly control the urea's drop into the screw conveyor hopper allows the material to enter the conveying pipeline at a steady rate, minimizing collisions with the silo walls.

Tie the rope to put urea into the hopper of the screw conveyor Application

In the agricultural sector, small and medium-sized farms use this method to feed urea into the hopper of a screw conveyor. The conveyor then transports the urea to a fertilizer spreader, achieving precise fertilization and avoiding the unevenness of manual spreading. In fertilizer processing plants, bagged urea needs to be transferred to storage silos after production. Ropes are used to tie the urea into the hopper of a screw conveyor, reducing breakage during manual handling. In wastewater treatment, urea, a key denitrification agent, requires continuous, proportional addition. Operators use ropes to slowly drop urea into the hopper of a screw conveyor. Combined with the conveyor's quantitative delivery function, this ensures accurate dosing of the agent in the wastewater treatment system and ensures that treated water quality meets standards.

Tie the rope to put urea into the hopper of the screw conveyor fully combines the physical properties of urea with the advantages of a screw conveyor with a hopper, achieving a balance between cost and efficiency while ensuring operational safety and material quality. It embodies the combination of humanized design and mechanized efficiency in industrial processes, ensuring smooth and safe urea transportation from storage to delivery. Whether it is fertilization and feeding in agricultural production or urea processing and treatment in the industrial field, this operation has become a key link in the urea treatment process of some companies due to its flexibility, economy and practicality.