Titanium dioxide flexible screw conveyor

Monday January-26 2026 16:31:27

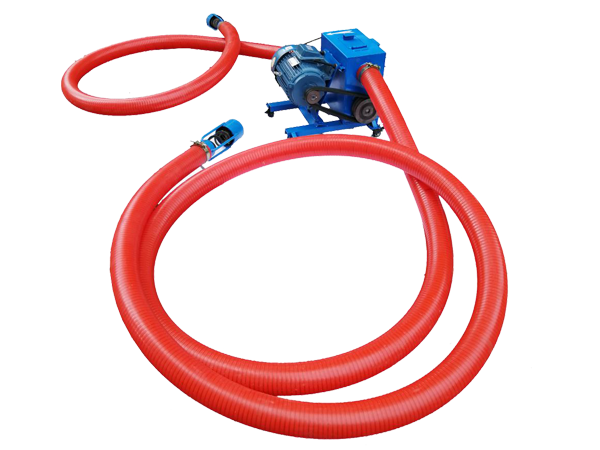

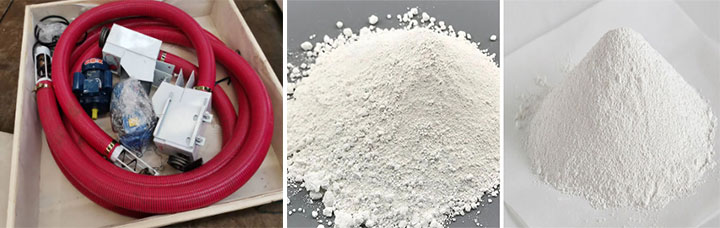

Titanium dioxide is a white powder. Titanium dioxide flexible screw conveyor can transport titanium dioxide to silos, mixing tanks, and other equipment to produce coatings, cosmetics, and other products. Before conveying, the equipment can be equipped with pipes of various diameters, such as 76mm, 102mm, 127mm, and 152mm. The conveying capacity ranges from approximately 0.5 to 15 m³/h, varying depending on the material characteristics. The equipment can be fixed in one location, handheld, or moved to different positions according to the production environment, offering high flexibility.

Components of the Titanium Dioxide Flexible Screw Conveyor

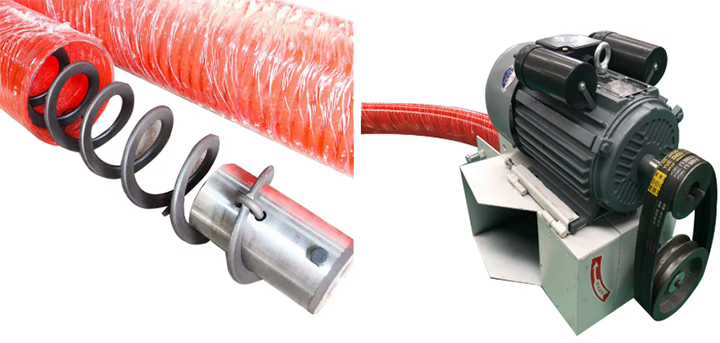

The built-in spiral of the Titanium Dioxide Flexible Screw Conveyor is made of stainless steel, which is wear-resistant and corrosion-resistant. It uses flange connections or quick-release connections for easy disassembly and cleaning. The conveying pipe is a wear-resistant, thickened flexible hose, which can be customized in lengths of 3m, 5m, 10m, and 20m to facilitate the conveying of titanium dioxide over different distances. Because both the hose and spiral are flexible, the equipment can convey titanium dioxide at various angles, including horizontal, inclined, and vertical, providing great flexibility for titanium dioxide transport. The equipment can use a three-phase asynchronous geared motor or an explosion-proof motor to suit the titanium dioxide production environment.

What are the advantages of a titanium dioxide flexible screw conveyor?

The titanium dioxide flexible screw conveyor is flexible, supporting any combination of horizontal, vertical, and inclined configurations without the need for complex steering mechanisms. When conveying titanium dioxide, the screw propels the material while slightly mixing it, preventing clumping. The small gap between the screw and the pipe wall reduces titanium dioxide adhesion as the screw rotates. The equipment can be equipped with frequency converter control to achieve continuous or batch quantitative conveying, meeting the batching requirements of different working conditions.

Titanium dioxide flexible screw conveyor parameters

| Item | Parameter |

| Equipment Name | Titanium dioxide flexible screw conveyor |

| Material Bulk Density | 0.8 — 1.6 t/m³ |

| Conveying Capacity | 0.5 — 20 m³/h |

| Conveying Length | 1 — 10 m (customizable up to 15 m) |

| Conveying Angle | 0° — 45° |

| Screw Diameter | Ø76 / Ø89 / Ø114 / Ø102/ Ø127/ Ø152 mm |

| Hose Inner Diameter | Ø90 — Ø140 mm |

| Screw Speed | 200 — 1400 rpm (adjustable) |

| Motor Power | 0.75 — 7.5 KW |

| Voltage | 380V / 50Hz (customizable) |

| Hose Material | Food-grade PU or wear-resistant rubber |

| Screw Material | Spring steel or carbon steel |

| Frame Material | Carbon steel / Stainless steel (optional) |

| Working Temperature | -10℃ to +80℃ |

| Installation Type | Mobile / Fixed |

| Dust-proof Design | Fully enclosed conveying |

| Control Mode | On/Off or frequency control |

Titanium dioxide flexible screw conveyor applications

The titanium dioxide flexible screw conveyor can transport titanium dioxide from a powder mixer to a granulator. When conveying the mixed titanium dioxide composite powder, it gently propels the powder without disrupting particle dispersion, preventing agglomeration that could affect the color uniformity of the finished plastic product. The equipment can also transport titanium dioxide from a silo to a metering scale, achieving quantitative feeding to match the proportion of fillers added in papermaking, avoiding excessive or insufficient amounts that could affect paper whiteness and strength. The equipment can also transport titanium dioxide from the ton bag unpacking station in the storage area to the workshop silo, solving the problem of cross-area transportation between storage and production workshops. The flexible pipe can bypass workshop equipment, eliminating the need for replanning the factory layout.

When selecting a titanium dioxide flexible screw conveyor, everything from the pipe diameter and length to the material can be customized according to the titanium dioxide conveying needs or production scenario. The flexible screw conveyor provides an excellent conveying solution for the production of products such as coatings, plastics, papermaking, printing inks, and cosmetics by transporting titanium dioxide to designated locations.