Titanium dioxide screw conveyor

Friday January-16 2026 17:29:35

Titanium dioxide screw conveyor can transport powdered or finely granulated titanium dioxide. It uses rotating helical blades to stably convey titanium dioxide from the feed end to the discharge end within a closed conveyor housing. Its conveying capacity typically ranges from 0.5 to 30 tons per hour. Screw diameters are available in various sizes, including 102mm, 159mm, 219mm to 400mm. Motor power is generally 1.5–11 kW. Single-unit length ranges from 2 to 12 meters, and custom lengths are available. The machine's tilt angle typically does not exceed 30°. The equipment supports quantitative conveying and can be equipped with frequency converter control to adjust the conveyor speed according to the conveying conditions, thereby controlling the conveying volume.

How does the Titanium dioxide screw conveyor work?

The Titanium dioxide screw conveyor uses a motor-driven reducer to continuously rotate the helical shaft. After the titanium dioxide powder enters through the feed inlet, it moves axially under the push of the helical blades. For fine-sized titanium dioxide particles, a small-pitch, low-speed design can be used to reduce dust and material compaction. Adding anti-bridging devices, anti-static designs, or surface polishing treatments can also improve titanium dioxide conveying.

Titanium Dioxide Screw Conveyor Types

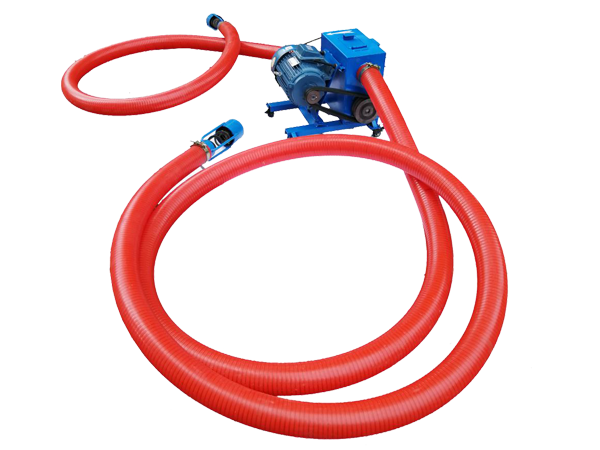

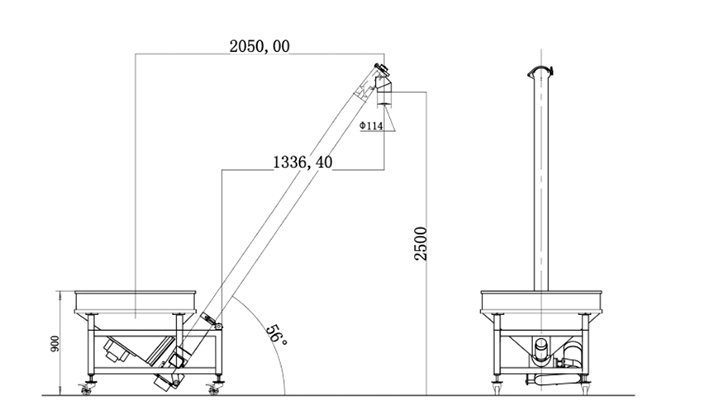

For titanium dioxide conveying, two types of screw conveyors are available: flexible hose screw conveyors and stainless steel screw conveyors. If space is limited, a flexible hose screw conveyor can be chosen; if it needs to be used in conjunction with other equipment, a stainless steel screw conveyor is preferable.

Flexible hose screw conveyors have a conveying capacity of approximately 0.5~3 m³/h, suitable for short-distance, light-load conveying. This type uses a flexible hose as the conveying channel, allowing for flexible conveying, low noise, and minimal damage to the material. The machine can convey horizontal distances up to 15 meters and vertical heights up to 6 meters, and can be used for titanium dioxide transfer or quantitative feeding.

Stainless steel screw conveyors have a conveying capacity of 5~20 m³/h. The hopper can temporarily store a certain amount of titanium dioxide, ensuring continuous supply. It can directly lift and transport titanium dioxide from the ground or lower levels to the feed inlet of higher process equipment. Made of stainless steel, it is corrosion-resistant and non-adhesive, suitable for conveying hygroscopic and easily agglomerated titanium dioxide powder. It is suitable for batch conveying, lifting, storage docking, or uniform feeding before packaging on production lines.

Titanium dioxide screw conveyor price

For the basic model with a pipe diameter ≤165mm and a length of 3-5 meters, the price of a titanium dioxide screw conveyor is $160-$880 per unit. This type of model has a compact structure and is suitable for small-scale chemical applications. For the standard model with a pipe diameter of 219-323mm and a length of 6-10 meters, with a conveying capacity of 49-110 tons/hour, the price is $1580-$3500 per unit. This type is mostly made of stainless steel, which has strong corrosion resistance and can handle heavier titanium dioxide conveying needs.

Titanium dioxide screw conveyor manufacturers

Titanium dioxide screw conveyor manufacturers are located in China, Europe, and North America. Dahan Machinery in China has advantages in customization and price, capable of customizing machines based on the characteristics of titanium dioxide, and has successful case studies of titanium dioxide conveying. European and North American manufacturers have extensive experience in high-end sealing, automation, and long-term stability. For machines offering high cost-performance and good customization capabilities, Chinese manufacturers are recommended; for machines with stable function and more precise manufacturing, manufacturers in Europe and other countries are preferable.

Titanium dioxide screw conveyor case study

A paint manufacturing company faced problems with material agglomeration, bridging, and dust leakage when conveying titanium dioxide powder in the batching process. The company later selected a 120mm diameter, 8m long stainless steel flexible screw conveyor, and installed a vibration anti-bridging device and a nitrogen-sealed dustproof structure. The titanium dioxide screw conveyor is installed between the titanium dioxide storage silo and the batching scale. During operation, the silo opening vibration device breaks up agglomerated materials and prevents blockage. After the equipment was put into use, the titanium dioxide conveying efficiency increased by 30%, solving previous production problems.

The titanium dioxide screw conveyor can be flexibly customized in terms of conveying capacity, structural form, and control method according to different process requirements. Flexible screw conveyors and inclined stainless steel screw conveyors with hoppers can be selected according to specific working conditions. Whether conveying titanium dioxide from storage tanks to mixers, to slurry preparation systems, or as a raw material or intermediate in continuous production processes, this machine can stably complete the conveying of titanium dioxide.