Tubular shaftless screw conveyor manufacturers

Monday December-15 2025 12:50:26

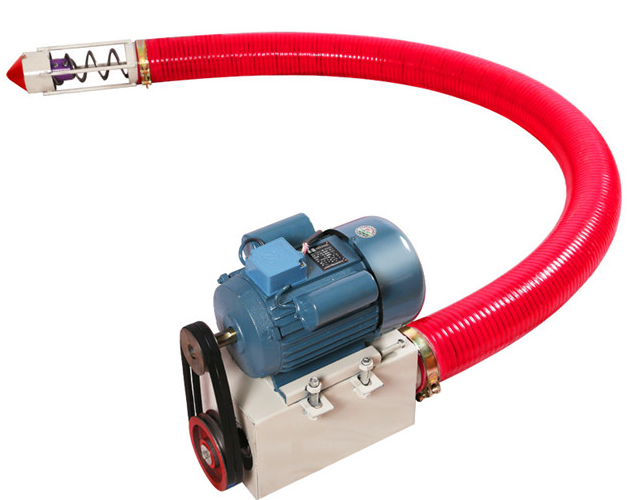

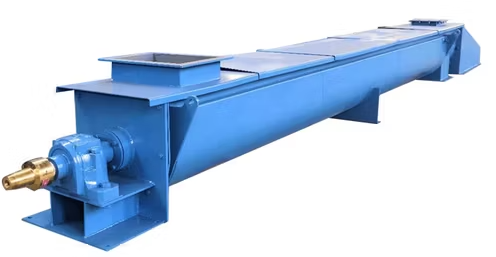

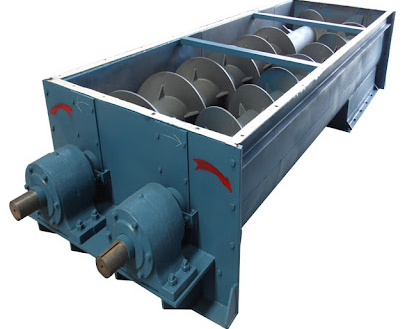

Tubular shaftless screw conveyor manufacturers are located in countries such as the United States, the United Kingdom, Germany, and China. These manufacturers produce machines that reduce clogging when conveying viscous and irregular materials, and utilize wear-resistant materials such as wear-resistant steel and stainless steel to extend machine life. Screw diameters range from Ø150 to Ø600 mm, with conveying capacities from 0.5 m³/h to 45 m³/h, meeting conveying needs from small batches to large volumes. The following introduces suppliers from aspects such as manufacturer characteristics, technical parameters of their models, applicable scenarios, and precautions.

Characteristics of Tubular Shaftless Screw Conveyor Manufacturers

Tubular shaftless screw conveyor manufacturers each have their own characteristics in manufacturing them. Some produce machines with higher precision, some offer a wider variety of models, and some excel in customized designs. The following is an analysis of the characteristics of manufacturers from different countries.

The United States has manufacturers specializing in shaftless screw conveyors for waste disposal and food processing, emphasizing on-site maintainability and anti-winding design. Specifically designed for transporting difficult-to-transport materials such as waste, food scraps, and kitchen waste, these conveyors emphasize easy disassembly and inspection, blade replacement, and anti-winding design.

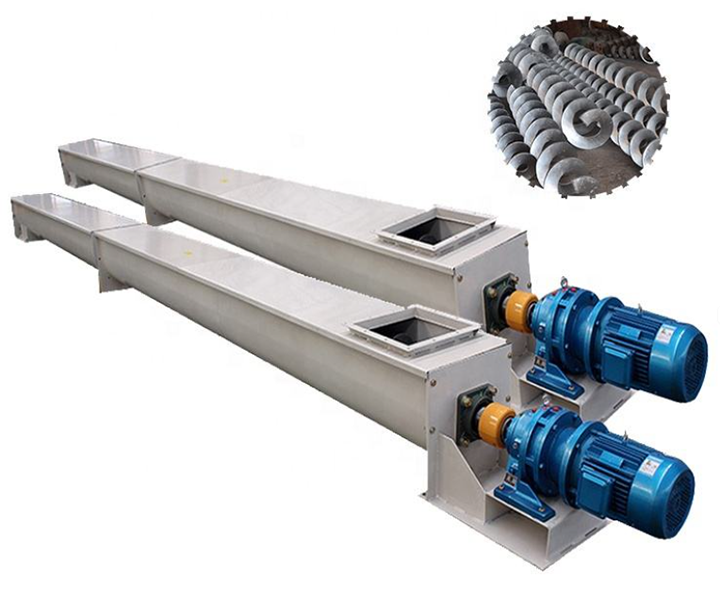

China's Dahan Machinery manufactures a variety of Tubular shaftless screw conveyors, including tubular, U-shaped, and dual shaftless types. They offer fast delivery and can customize materials, liners, and blade specifications according to customer requirements. Their prices are usually more competitive, making them a good choice for those with limited budgets or those needing rapid delivery.

German manufacturers prioritize engineering fit, material selection, and long-term reliability. They commonly use wear-resistant liners, replaceable liners, and standardized testing, making them suitable for heavy-duty, entangled, or sandy/gravelly-containing conditions. They have strong engineering capabilities and can provide complete solutions and on-site commissioning. Their prices are relatively higher.

Tubular shaftless screw conveyor manufacturers - Technical Specifications

| Manufacturer | Typical Model | Screw Diameter (mm) | Outer Diameter (mm) | Maximum Length (m) | Typical Capacity (t/h or kg/h) | Motor Power (kW/HP) | Maximum Inclination Angle (°) | Material |

| Dahan Machinery |

WLS150/WLS200/ WLS250/WLS300/ WLS400/WLS500 |

150/184/ 237/284/ 365/470 |

180/219/ 273/351/ 402/500 |

Single Section: Up to 12-25 m (Varies by Model) |

2.4/7/9/13/ 18/28 (t/h, Based on Model) |

L ≤ 7m: 1.5/2.2/3/5.5/ 11/11 (kW); L > 7m: Equipped with Larger Motor Separately |

0-30° | Commonly Used for Sludge Conveying, Equipped with Sealed Structure Configured According to Model |

| WX Conveyor | Tube Type Shaftless (Example) | Ø Screw as per Example ~326 | Outer Casing Tube Ø326×6mm | 3.37m | 15,000kg/hr (Approx. 15t/h) | Configured According to Example Project | Commonly Used for Horizontal or Low-Inclination Applications | Outer Casing Example: 316L Stainless Steel; Screw: Continuous Welded Type, Suitable for Sealed Sanitary Conveying |

| BEMA | Tube Type Inclined Shaftless Conveyor | Ø191/Ø240 | Carbon Steel | 4.5-5.0m | Customized According to Project | Configured According to Project | Inclined Conveyor for Project (Customizable on Demand) | Screw Material Example: Hardox-450; Casing: Carbon Steel, Painted in Customer-Specified Color |

| RATAJ (Czech Republic, Explosion-Proof/Special Model) | RL Series/Special Shaftless Model | Multiple Specifications (Based on Model) | Multiple Specifications (Based on Model) | Available in Extended Length with Special Explosion-Proof Design | Explosion-Proof Specifications for Coal Handling, Etc. (Parameters Based on Model) | Explosion-Proof/Special Grade Motor Configured as Required | Designed for Explosion-Proof Applications (Example Data: 1.0MPa Explosion-Resistant Structure) | ATEX/Explosion-Proof Versions Available; Material and Dimensions Customized According to Working Conditions |

| INOTEK (Inotek) | Shaftless Screw Conveyors (Standard Series) | Multiple Specifications | Multiple Specifications (Based on Order) | Standard Version Supports Multi-Section Splicing | Highlighted Features: High Filling Rate & Shaftless Advantages (Capacity Calculated Based on Material Type) | Configured According to Machine Type/Length | Suitable for Common Conveying Inclination Angles (Recommended ≤ 30°) | Zero-Clearance Installation Recommended; Wear-Resistant Lining or UHMW Bushing Commonly Adopted to Extend Service Life |

Tubular shaftless screw conveyor manufacturers - Application Scenarios

Tubular shaftless screw conveyor manufacturers' models are used in urban wastewater treatment and sanitation projects, paper and wood processing industries, building materials and chemical production, energy, environmental protection and biomass fields, ports and shipping, and other scenarios.

For conveying fibrous, easily entangled screenings, dewatered sludge, kitchen waste, and municipal solid waste, its shaftless design prevents clogging, and its sealed structure prevents sewage and odor leakage. For conveying long-fiber materials such as sawdust, pulp, and waste paper, traditional shafted screw conveyors are prone to fiber entanglement and jamming, but the shaftless design solves this problem. For conveying cement raw materials, fly ash, ceramic slurry, and viscous chemical raw materials, its fully enclosed structure provides dust and moisture protection. In biomass power plants and biogas projects, it is used to convey irregular biomass fuels such as straw and wood chips, or fermented biogas residue, and its anti-entanglement capability ensures stable feeding. It is also suitable for conveying viscous, unevenly sized bulk materials such as coal and ore slag in ship holds and docks; the equipment can operate in inclined or horizontal positions, adapting to complex loading and unloading environments.

What should you consider when choosing a Tubular shaftless screw conveyor manufacturer?

When choosing a Tubular shaftless screw conveyor manufacturer, you should consider aspects such as technology, quality, and experience. The choice of materials for the shaftless screw conveyor and the tubing, as well as the overall machining precision, welding quality, and anti-corrosion treatment, determine the equipment's service life and operational stability. You can request successful case studies from manufacturers that match or are similar to your application scenario. Inquire whether the manufacturer provides installation guidance, commissioning support, spare parts supply speed, response time, and other services. Use this information to select a suitable manufacturer.

Tubular shaftless screw conveyor manufacturers are located globally. Choose the appropriate manufacturer based on your specific needs. If you require precision manufacturing, durability, and a high degree of automation, choose a European manufacturer. If you prioritize fast market response, strong customization capabilities, and high cost-effectiveness, choose a Chinese manufacturer.