What is a silica sand flexible conveyor?

Tuesday May-20 2025 16:34:36

A silica sand flexible conveyor is a device specially used for conveying granular or powdered materials such as silica sand. It has flexible layout adaptability and is suitable for complex production environments. Equipment that transports silica sand from one place to another through a flexible structure or adjustable path is widely used in silica sand production, processing or application scenarios to meet non-linear paths, multi-point unloading or complex space requirements.

Applicability of silica sand

Silica sand is a non-metallic mineral with high hardness and different particle sizes. Whether the flexible conveyor is suitable for it needs to consider the following points:

1. Particle size range

Flexible conveyors are suitable for silica sand with a particle size between 0.1mm and 5mm, especially dry particles with good fluidity.

For materials that are too fine (such as powder) or have large differences in particle size, it is necessary to confirm that they will not cause "bridging" or blockage.

2. Moisture content

Silica sand with low moisture content (<2%) is more suitable for flexible conveying to avoid adhesion and increased conveying resistance.

It is recommended to use flexible screw conveyors with caution for high-humidity silica sand, and closed chain conveying equipment with scraper structure can be considered.

3. Abrasiveness

Silica sand has strong abrasiveness, and long-term conveying is prone to wear of screws, chains and other parts.

It is recommended to use wear-resistant materials (such as manganese steel, stainless steel 304/316, polyurethane lining) to improve durability.

The silica sand flexible conveyor is suitable for medium-fine silica sand with good fluidity, dryness, and small to medium production capacity and high layout flexibility requirements; process flow with closed conveying and environmental protection control requirements.

Comparison with rigid conveying equipment

|

Project |

Flexible conveyor |

Rigid conveyor (such as ordinary screw conveyor) |

|

Layout flexibility |

High |

General |

|

Installation difficulty |

Low |

High |

|

Cost |

Medium |

Low to Medium |

|

Life of wearing parts |

Medium |

High (rigid blades are wear-resistant) |

|

Maintenance convenience |

High |

General |

Working principle of silica sand flexible conveyor

The working principle of the flexible screw conveyor is similar to that of the traditional screw conveyor, which mainly relies on the rotating spiral blades to push the material forward in the closed tubular or U-shaped groove. Unlike the traditional screw conveyor, the spiral body of the flexible screw conveyor is usually made of a flexible shaft or special flexible material, which enables it to bend to a certain extent to adapt to different installation paths.

When the spiral blade rotates, the material is forced to move by the spiral blade, and continuous conveying is achieved under the action of gravity, friction and centrifugal force.

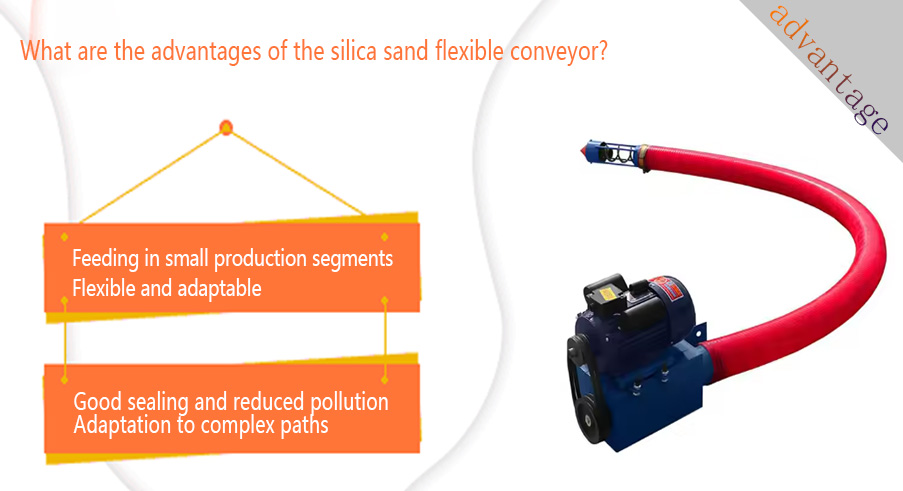

What are the advantages of the silica sand flexible conveyor?

Feeding in small production segments: For small and medium-sized systems with daily processing volumes ranging from several tons to tens of tons, flexible conveyors can achieve quantitative and stable feeding, and are easy to use with packaging machines, mixers and other equipment.

Flexible and adaptable: Due to the flexibility of the spiral body, the conveyor can be installed along a curved path, avoiding the need for a large number of corner devices, thereby reducing the footprint and potential blockage points. This makes it particularly suitable for occasions where space is limited or multiple points of inlet and outlet are required.

Good sealing and reduced pollution: Silica sand, as a fine particle material, is prone to dust during transportation. Flexible screw conveyors usually adopt a fully enclosed tubular structure, which can effectively prevent dust leakage, reduce environmental pollution, and protect the health of operators. For silica sand that requires high cleanliness.

Adaptation to complex paths: Flexible conveyors (such as flexible chain or pneumatic conveyors) can achieve curved, inclined or multi-point feeding/unloading, adapt to production lines with limited space or non-linear layout, and are particularly suitable for the complex environment of silica sand processing plants.

Recommended mesh number for silica sand flexible conveyor

|

Mesh number range (mesh) |

particle size range (mm) |

Applicable scenarios |

Precautions |

|

4-20 mesh |

4.75-0.85mm |

Glass, ceramics, building materials production, coarse-grained silica sand transportation |

Choose a large-diameter spiral or wear-resistant hopper to avoid blockage |

|

20-60 mesh |

0.85-0.25mm |

Photovoltaic, chemical, mineral processing, small and medium-sized silica sand transportation |

Preferentially use stainless steel to avoid pollution |

|

60-120 mesh |

0.25-0.125mm |

High-purity silica sand (photovoltaic, semiconductor), fine chemicals |

Pneumatic conveying is suitable for long distances |

|

120-325 mesh |

0.125-0.045mm |

Ultrafine silica powder, electronic materials, coating production |

High sealing and anti-static design are required |

|

>325 mesh |

<0.045mm |

High-purity silica powder, nano-level material transportation |

Low-speed pneumatic conveying is required to avoid particle crushing |

What can the silica sand flexible conveyor be used for?

Due to the abrasiveness, particle size and cleanliness requirements of silica sand, flexible screw conveyors have a wide range of uses in the production, processing, storage and application of silica sand, such as:

① High-purity silica sand production line: In the purification, drying, screening, rounding, packaging and other links of high-purity silica sand, silica sand needs to be transported from one process to the next process, and flexible conveyors can ensure the cleanliness and continuity of materials.

② Glass, ceramics, refractory materials, and building materials industries: These industries are the main application areas of silica sand. Flexible conveyors can be used for the transportation and batching of silica sand raw materials in these factories to achieve automated and continuous material supply.

③ Production lines that require flexible layout: For example, materials need to be lifted from the ground to a high silo, or transported from one floor to another.

In general, the silica sand flexible conveyor is an efficient, environmentally friendly and adaptable material transportation solution, especially suitable for handling granular, dusty and abrasive materials such as silica sand.