What types of belt conveyors are there?

Friday May-23 2025 16:03:49

According to the belt structure, there are ordinary flat belt conveyors, sidewall belt conveyors, trough belt conveyors and corrugated sidewall belt conveyors, of which the latter three are suitable for large-angle or even vertical conveying. In addition, there are telescopic conveyors, which are often used for loading and unloading goods. In general, there are various types of belt conveyors. It is necessary to select the appropriate model according to factors such as material characteristics, conveying distance, and spatial structure to improve efficiency and reduce energy consumption.

①Classification by installation method:

Fixed belt conveyor: Usually installed in a preset fixed position, with a solid structure, suitable for granular materials with high density such as ore, coal, sand and gravel, fertilizer, cement, and grain (such as wheat and corn grains), with a granular size of generally between 0.5-100mm, and continuous conveying of powdered materials such as cement and fertilizer.

Conveying speed: Generally between 0.8-3.15 m/s. In the production lines of mines, ports, and large factories, it can stably and efficiently complete long-distance and large-volume material transportation.

Conveying capacity: up to 2,400 tons/hour (grain)

Mobile belt conveyor:The bottom usually has wheels or tracks, which can be easily moved between different operating points, with high flexibility and adaptability. They are often used in situations where the working position needs to be changed frequently. The equipment can also be used to transport grains, corn, beans, wood chips, waste and other small-particle bulk materials, and can adapt to the loading and unloading needs of different materials.

Conveying capacity: Usually small and medium-sized, the designed conveying capacity is usually small, but it can meet most needs within its application range. The specific conveying capacity depends on the model, belt width and conveying speed.

Conveying speed: Generally around 0.5-2 m/s.

② Classification by conveying line:

According to the form of the conveying line, belt conveyors can be divided into horizontal belt conveyors, inclined belt conveyors, vertical belt conveyors, turning belt conveyors and combined belt conveyors. They are designed according to the terrain and process requirements and have different structures and usage characteristics.

|

Type |

Picture |

Suitable for conveying materials |

Conveying capacity (t/h) |

Conveying speed (m/s) |

Characteristic description |

Uniqueness |

|

Horizontal belt conveyor |

|

Granular, blocky, packaged materials, such as grain, coal, ore, etc. |

50~2000 (depending on the width of the belt) |

0.8~2.5 |

Simple structure, stable operation, wide application, suitable for occasions where there is no height difference in the conveying path |

Low cost, convenient maintenance, and the basic form of belt conveyor |

|

Inclined belt conveyor |

|

Powdered and granular materials that are easy to slip or have good fluidity |

30~1500 |

1.0~2.0 |

Anti-slip belts can be designed according to the inclination angle, suitable for continuous conveying with a certain height difference |

Space saving, often used in construction, mining and other occasions where materials need to be lifted |

|

Vertical belt conveyor |

|

Powdered, small particles, such as quartz sand, fertilizer, flour, etc. |

10~500 |

0.2~1.0 |

Mostly use skirt baffle belts, which can achieve nearly 90° lifting and good continuity |

Small footprint, strong vertical lifting capacity, one of the alternatives to bucket elevators |

|

Turn belt conveyor |

|

Packaging, small particles, light industrial products |

5~300 |

0.5~1.5 |

Can realize the change of conveying direction, commonly used in assembly lines and automated logistics systems |

Support 30°~180° turning, flexible layout, adapt to narrow or special-shaped spaces |

|

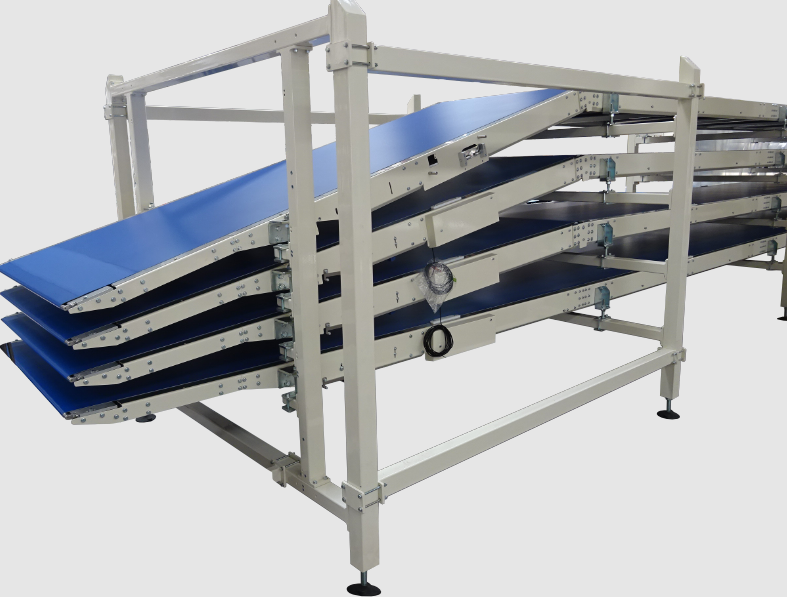

Combined belt conveyor |

|

All kinds of powders and block materials, adapt to various process requirements |

50~1500 (comprehensive type) |

0.5~2.0 (depending on the section) |

Composed of a combination of various line types, can cross multiple layers, turn, and variable slope conveying |

Flexible layout, adapt to complex space and variable conveying needs, common in large industrial systems |

③Classification by belt structure:

1.Ordinary flat belt conveyor

Structural features: The belt runs on a flat frame, usually equipped with upper and lower rollers. Suitable for conveying block, granular or piece materials.

Applicable scenarios: Suitable for horizontal or small-angle (generally <20°) material transportation, widely used in food, chemical, building materials, light industry and other industries.

2.Sidewall belt conveyor (generally refers to sidewall belt)

Structural features: Fixed sidewalls are installed on both sides of the belt to prevent materials from rolling down during inclined transportation. A cross partition can be added to form a bucket-shaped structure to improve the material lifting capacity.

Applicable scenarios: Suitable for conveying occasions with an inclination of 20° to 45°, commonly used in construction, metallurgy and other industries, used to convey sand, gravel, coal and other materials that are easy to roll down.

3.Corrugated sidewall belt conveyor (large-angle belt conveyor)

Structural features: The conveyor belt has a wavy flexible sidewall and a transverse partition (skirt belt + cross partition), which can achieve large inclination or even vertical transportation.

Applicable scenarios: Suitable for conveying powdery, small particles or small block materials, often used in limited space layout occasions, instead of bucket elevators.

4.Trough belt conveyor (also called trough belt conveyor)

Structural features: The conveyor belt forms a "trough" through the roller frame to increase the material carrying capacity. The middle roller forms a certain angle (generally 10°~35°).

Applicable scenarios: Suitable for long-distance, large-capacity continuous transportation, widely used in coal, mining, electricity and other industries.

5.Telescopic belt conveyor

Structural features: The length can be adjusted within a certain range. It is usually composed of one or more sections of telescopic structure, with strong flexibility and easy movement.

Applicable scenarios: Commonly used in warehousing, loading, docks and other occasions to improve material loading and unloading efficiency and reduce manual handling.

These different types of belt conveyors jointly build the arterial system of modern industry and logistics to ensure the efficient, safe and economical flow of materials. In practical applications, the choice of which type of conveyor needs to comprehensively consider multiple factors such as material characteristics, conveying volume, conveying distaance, on-site space, investment budget, etc.