White Sugar Flexible Screw Conveyor

Thursday January-15 2026 17:27:25

White sugar flexible screw conveyor can continuously transport granulated and powdered white sugar. Its flexible hose inner diameter ranges from 50–200 mm, and the conveying length is typically between 3–15 meters, which can be increased depending on space requirements. Its conveying capacity ranges from 0.5–20 tons/hour, suitable for both small-scale production lines and larger-scale conveying needs. The equipment can perform horizontal conveying over a maximum distance of 15 meters, as well as vertical conveying up to 10 meters in height. All core components that come into direct contact with the material are made of food-grade 304 or 316 stainless steel, preventing contamination and corrosion of the sugar. Two models are available: a stainless steel inclined screw conveyor and a flexible hose screw conveyor.

White Sugar Flexible Screw Conveyor Components

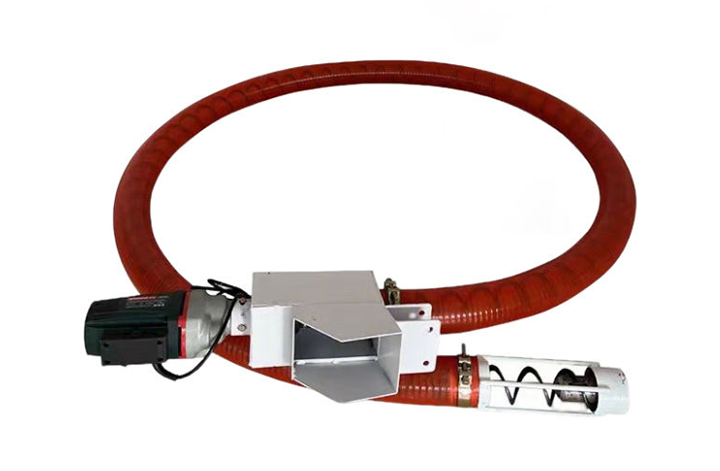

For the clean transport characteristics of white sugar, the components of the white sugar flexible screw conveyor include a flexible screw made of stainless steel that does not contaminate the sugar during transport; it can be equipped with a sealed hopper to isolate moisture and prevent sugar from clumping; it can be equipped with a variable frequency drive motor to adjust the conveying speed according to the properties of the sugar, avoiding clumping due to excessive heat during transport; the rounded discharge chute eliminates dead corners and reduces discharge residue.

Advantages of the White Sugar Flexible Screw Conveyor

White sugar has fluidity, and the rotating screw of the white sugar flexible screw conveyor can propel this material. The continuous rotation of the screw prevents the sugar from clumping due to slight moisture, ensures uniform sugar granules, and has a low breakage rate of sugar crystals, maintaining the integrity of the granules. The flexible screw conveyor is sealed from feeding to discharging, preventing external dust, insects, etc., from contaminating the sugar, preventing sugar powder from escaping, avoiding cross-contamination, and reducing sugar waste. The machine can be connected with quick-release clamps, has no internal bearings or lubrication points, and can be dry-cleaned or rinsed. Flexible conveyors can transport materials horizontally, inclined, or vertically, and can bypass obstacles. Their conveying pipes are flexible, which is advantageous when factory space is limited or when it's necessary to bypass equipment or pipelines.

White Sugar Flexible Screw Conveyor Type

Due to the hygroscopic and clumping properties of white sugar, the choice of conveying equipment depends on the sugar's condition: a stainless steel inclined screw conveyor or a flexible screw conveyor.

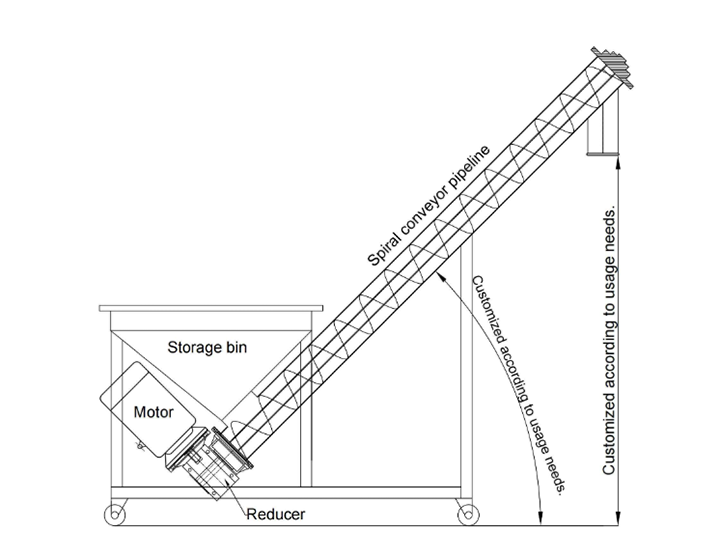

White sugar is prone to hygroscopic clumping, so a stainless steel inclined screw conveyor can be used when conveying wet sugar. This type is made of SUS304 stainless steel, which is corrosion-resistant and easy to clean. Its rigid screw provides a pushing and agitating force during inclined conveying, breaking up clumps of sugar and preventing blockages and adhesion during transport.

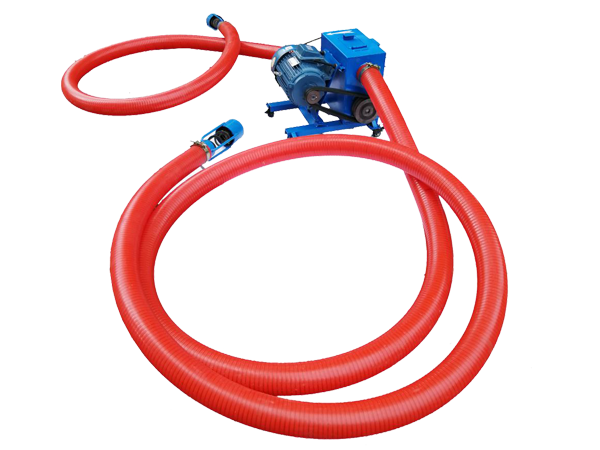

A flexible screw conveyor can be used when conveying dry sugar. This type of equipment is lined with food-grade PU or PVC flexible tubing, and the screw is a stainless steel spring. The tubing can be flexibly arranged in multiple directions, and the entire machine is lightweight and has a small footprint. It effectively protects the integrity of the sugar crystals, preventing breakage.

White sugar flexible screw conveyor for sale

Prices for white sugar flexible screw conveyors vary depending on the model. Stainless steel inclined screw conveyors with a conveying capacity of 1-5 tons/hour, a length of 3-5 meters, and a power of 2-4 kW cost between $2,500 and $4,500. Conveying capacities of 5-20 tons/hour, lengths of 5-10 meters, and power configurations of 4-7.5 kW cost approximately $4,000 to $6,000. Screw conveyors with a 100mm diameter hose, a length of 3-6 meters, and made of food-grade PVC hose cost between $1,500 and $2,700 and can be used handheld for short-distance transport of white sugar.

Operation of White Sugar Flexible Screw Conveyor

For stainless steel inclined screw conveyors, run them unloaded for about 2 minutes before starting to ensure there are no abnormal noises and the speed is normal. Then, slowly and evenly add white sugar to avoid overloading or clogging due to excessive feeding at once. Before stopping, stop feeding and wait until all the white sugar has been conveyed before shutting down. For flexible screw conveyors, align the feed hopper with the white sugar raw material, connect the power, and run unloaded to confirm the correct conveying direction and smooth operation before adding material. The feeding process should be slow and continuous. When moving equipment, stop the machine and disconnect the power first. After use, empty any remaining white sugar from the hose to prevent it from drying out and clumping.

The white sugar flexible screw conveyor can convey various types of white sugar, including granulated sugar, powdered sugar, refined sugar, and crystalline sugar. The machine can smoothly and continuously transport sugar from storage bins, hoppers, or packaging bags to mixers, packaging machines, or batching systems. This reduces the time and labor required for manual conveying and also reduces sugar spillage.