Coal screw conveyor

Commonly used in mining, power generation and cement industries. They can be used to move coal from one part of a facility to another, or to move coal from storage bins to boilers or other processing equipment.

Conveying length: 10-20 meters

Delivery capacity: 9-134m³/h

Inclination: horizontal or tilted below 20 degrees

Customization: material (carbon steel or stainless steel), screw shaft (with/without shaft, single shaft/double shaft), import and export distance, feed port size, etc. (customized on demand)

Introduction of coal screw conveyor

The coal screw conveyor can be used in power plants, rotary kilns or other scenes that require coal for coal transportation or the treatment of coal slag after coal combustion. It has good sealing performance and will not cause coal leakage or coal dust pollution. Compared with ordinary screw conveyors, the coal screw conveyor takes into account the special properties of coal transportation and adopts explosion-proof motors to ensure the safety of transportation. It can also be used in chemical plants , stone plant, etc. for the transportation of lime, cement, stone, etc.

Applications

Coal screw conveyors are commonly used in a variety of industries and applications, including:

Mining: Typically used in mining operations to transport coal from mines to processing plants or transport systems such as trains or barges.

Power generation: It can be used in power plants to transport coal from storage bins to boilers or other processing equipment. They can also be used to transport fly ash or other by-products of coal combustion.

Cement Production: Typically used in cement production facilities to transport coal from storage silos to kilns or other processing equipment.

Chemical processing: Used to transport solid fuels such as coal or biomass in chemical processing facilities.

Product advantages

1. Good sealing performance, avoiding the leakage of coal ash during the transportation process and causing production environment pollution or production accidents;

2. The conveying capacity is large, up to 142m³/h, which can meet the needs of coal processing or use;

3. There are various forms of transportation, which can be carried out horizontally, inclined or vertically, and can meet various forms of factory layouts such as coal-fired plants and power plants;

4. Explosion-proof motors are used, with high safety standards to ensure production safety.

Video

Product number

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

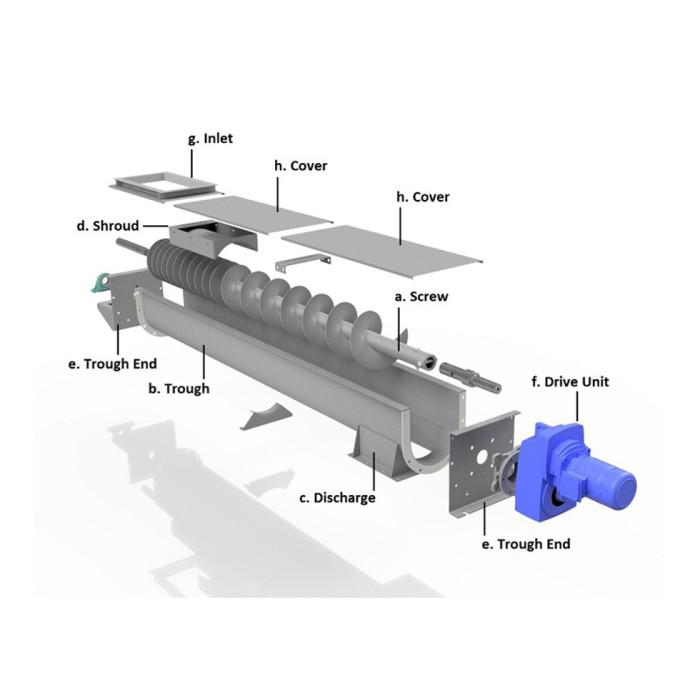

product structure

Coal screw conveyors typically consist of multiple components, including:

Auger or Auger: The Auger or Auger is the central piece of the conveyor and is responsible for moving the coal along the length of the conveyor. It usually consists of helical blades attached to a rotating shaft.

Trough: A trough is a structure that contains a screw or auger and guides the coal along the length of the conveyor. It is usually made of steel or another durable material designed to withstand the weight and abrasiveness of coal.

Drive unit: The drive unit is the mechanism that powers the screw or auger and usually consists of an electric motor, gearbox and coupling.

Bearings: Bearings are used to support the rotating shaft of a screw or auger so that it rotates smoothly.

Inlet and Outlet: Inlet is the point where coal enters the conveyor and outlet is the point where coal leaves the conveyor. These can be designed to suit the specific needs of the application, such as loading hoppers or discharge chutes.

Covers: Covers can be added to the conveyor to enclose the screw or auger and prevent the release of dust or other contaminants into the environment.

Solutions by Industry

Here are three customer cases of coal screw conveyors:

-

Coal Mining Operations

Coal mining operations use coal screw conveyors to transport coal from the mine to the processing plant. Screw conveyors are designed to handle the abrasive and heavy nature of coal and operate continuously to keep up with the production rates of mining operations. Coal is transported to processing plants where it is sorted, crushed and washed before being transported to power plants or other destinations.

-

Coal-fired Power Plant

Coal-fired power plants use coal screw conveyors to move coal from storage silos to boilers or other processing equipment. Screw conveyors are designed to handle the high temperatures and pressures of a power plant environment and run continuously to maintain a steady supply of boiler fuel. Coal is burned in boilers to produce steam, which is used to generate electricity.

-

Cement Production Facility

Cement production facilities use coal screw conveyors to transport coal from storage silos to kilns or other processing equipment. The screw conveyor is designed to handle the high temperature and abrasiveness of the coal and operates continuously to maintain a steady supply of fuel to the kiln. Coal is burned in kilns to provide heat for the cement production process.