Slag screw conveyor

Commonly used in steel mills, foundries and metal production facilities to handle and transport slag from smelting or refining processes. They efficiently convey slag from production areas, ensuring a clean, safe working environment.

Diameter: 200mm, 250mm, 300mm, 400mm, 500mm, 600mm

Length: 10-20 meters

Output: 134 cubic / hour

Speed: 13-75r/min

Introduction of Slag Screw Conveyor

The slag screw conveyor is used in the blast furnace slag micro-powder project. It is mainly a feeding device for the slag vertical mill. The equipment has good wear resistance and strong air lock function, which can indirectly reduce the excessive energy consumption of the vertical mill due to air leakage, thereby reducing energy consumption. The slag screw conveyor can be arranged horizontally or inclined according to the user's site requirements, and the inclination angle generally does not exceed 20°.

Application of Slag Screw Conveyor

The application of slag screw conveyors is mainly used in industries that generate slag as a by-product during the production process. Here are some common applications for slag screw conveyors:

Steel mills: Used to transport slag or slag from ladles to designated storage areas or disposal sites. These conveyors effectively handle the abrasive and granular nature of steel slag, ensuring smooth material flow and minimizing manual handling.

Foundry: Used to transport slag from the foundry area to a slag pit or recycling facility. By automating the material handling process, these conveyors increase operational efficiency and reduce the risk of manual handling injuries.

Power plants: Power plants using coal or biomass as fuel produce bottom ash and boiler slag as combustion by-products. Slag screw conveyors are used to transport slag material to ash handling systems such as ash storage silos or ash handling areas. Conveyors help to efficiently remove and dispose of slag, optimizing power plant operations.

Cement industry: For transporting slag from storage areas to mixing or grinding units. These conveyors ensure accurate and controlled addition of slag to the cement mix, facilitating the desired composition and quality of the final product.

Waste Management and Recycling: Transportation of slag to recycling facilities or designated disposal areas contributes to efficient waste management and resource recovery.

Construction: Used to transport slag to mixing or mixing plants where it is combined with other materials to form construction grade products. Conveyors help control the addition of slag, ensuring that the building material is of the desired composition and quality.

Video

Benefits of Slag Screw Conveyor

1. It adopts frequency conversion motor with a speed of up to 35 rpm, and can transport 105 tons of materials per hour.

2. A wear-resistant layer is added to the outer edge of the blade. This spiral blade is used as an anti-skid layer to prolong its service life.

3. The sealing performance is good, which can ensure the dust pollution of cinder in the process of conveying.

4. Multiple units can be connected in series according to the process requirements, and can also be used in conjunction with other equipment.

5. The heat insulation effect is good, and no cooling device is needed.

Working Principle of Slag Screw Conveyor

When the slag screw conveyor is started, due to the friction between the gravity of the slag material and the wall of the trough, the material can only move forward along the bottom of the conveyor trough under the thrust of the blades. Shipping is all about sliding. In order to make the screw shaft in a more favorable tension state, the driving device and the discharge port are generally placed on the same end of the conveyor, and the feed port is placed near the tail of the other end as much as possible.

Technical parameters

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

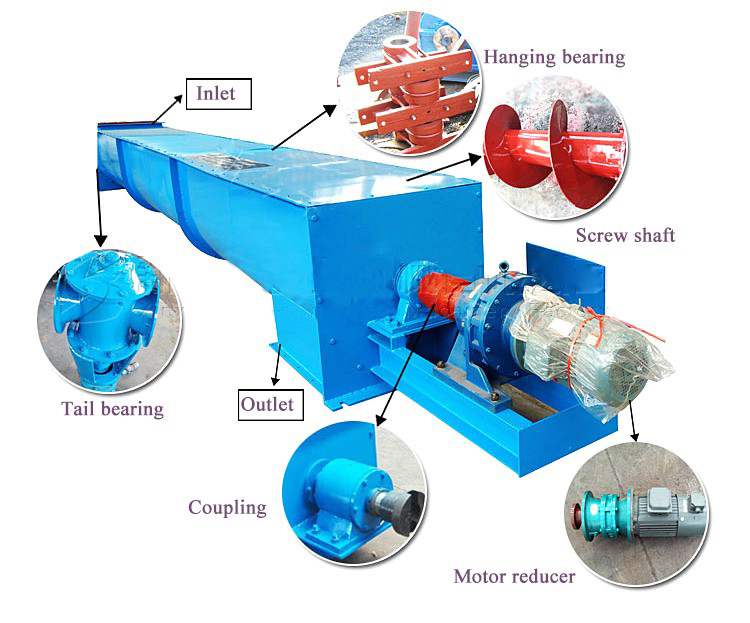

Structure of Slag Screw Conveyor

The structure of the slag screw conveyor generally consists of the following parts:

Auger: It is a helical metal blade that rotates in a slot. Usually made of a durable material, such as hardened steel, to withstand the wear and tear of slag.

Chute: The chute is usually U-shaped to prevent spillage and ensure efficient material transport. It is made of materials capable of withstanding slag corrosion, such as stainless steel or wear-resistant steel.

Drive Assembly: The drive assembly powers the rotation of the auger. It usually includes an electric motor, a gearbox or a belt drive system, and a coupling mechanism. The drive assembly provides the necessary torque and speed to rotate the auger and move the slag along the conveyor.

Material inlet and outlet: There is an inlet at one end of the slag screw conveyor for receiving slag materials, and an outlet at the other end for discharging materials. The inlet is designed to facilitate smooth and controlled entry of slag into the conveying system. The outlets may include features such as discharge chutes or sliding doors to direct the slag material to the desired location.

Support Structure: Keeps it stable and properly aligned. Support structures can vary according to specific application and installation requirements. It may include outriggers, brackets or frames to provide stability and ensure smooth operation of the conveyor.

Covers and Guards: To increase safety and protect the operator from contact with moving parts, slag screw conveyors are often fitted with covers and guards.

Screw conveyor in slag powder process

1. Raw material system

The slag raw material is transported to the slag pile by train, and after preliminary dehydration, the slag is sent to the receiving bin, and then transported to the drying room feeder by the conveyor.

2. Drying system

The slag in the silo of the drying room is fed into the dryer by the vibrating feeder for drying, the hot air required for drying is supplied by the coal-fired hot air stove in front of the dryer, and the dried slag passes through the screw conveyor, bucket It is sent to a steel bin by a type elevator, and then sent to a mill after iron removal by a belt conveyor.

3. Grinding system

The dried slag enters the mill for grinding, and the slag powder from the grinding is screened by the powder classifier, and the slag powder is sent back to the mill by the screw conveyor to continue grinding, forming a closed loop with the mill The qualified slag powder is sent to the finished product warehouse by the screw conveyor.

4. Finished product system

The slag powder production line has a finished product warehouse, and the finished slag powder is transported by a screw conveyor, and can be packaged and transported to the manufacturers in need.

Solutions by Industry

Here are three customer cases that highlight the application of slag screw conveyors in different industries:

-

Client: Steel Mill

Industry: Steel Manufacturing

Application: processing steel slag

A steel plant in Russia has adopted a slag screw conveyor in its production process to handle the steel slag produced in the smelting process. Screw conveyors efficiently transport abrasive slag from the furnace area to designated storage pits, ensuring a clean, safe working environment. A custom slag screw conveyor from a conveyor manufacturer improves material handling efficiency, reduces manual labor, and optimizes the entire steel production process.

-

Client: Power Plant

Industry: Power Generation

Application: Treatment of Boiler Slag

A power plant in Romania uses a screw conveyor to process boiler slag from the combustion process. Screw conveyors efficiently transport boiler slag from the boiler area to the ash handling system, where it is safely stored or disposed of. The robust design and wear-resistant components of the slag screw conveyor ensure reliable and continuous operation, contributing to the seamless operation of the power plant and compliance with environmental laws

-

Client: Waste Management Facility

Industry: Waste Management and Recycling

Application: Treatment of industrial waste

A waste management facility manufacturer in Vietnam uses a slag screw conveyor to process industrial waste for proper disposal and recycling. Screw conveyors efficiently transport slag from waste processing areas to designated recycling units or disposal areas. Custom slag screw conveyors from conveyor solutions provider improve waste management practices, reduce manual handling risks and increase operational efficiencies for facilities handling industrial waste.